Granular flow involves the movement of discrete solid particles that interact through collisions and friction, exhibiting behaviors such as jamming and segregation absent in fluid flow. Fluid flow refers to the continuous movement of liquids or gases governed by viscosity and pressure gradients, characterized by laminar or turbulent regimes. Understanding the distinctions between granular and fluid flow is essential for optimizing processes in industries like pharmaceuticals, agriculture, and materials handling.

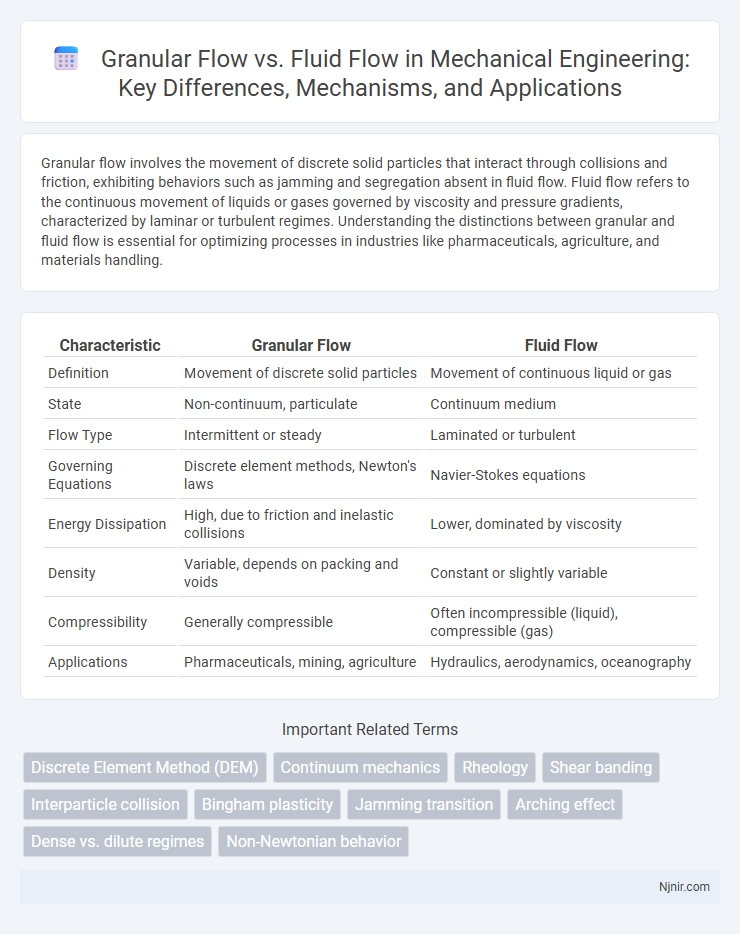

Table of Comparison

| Characteristic | Granular Flow | Fluid Flow |

|---|---|---|

| Definition | Movement of discrete solid particles | Movement of continuous liquid or gas |

| State | Non-continuum, particulate | Continuum medium |

| Flow Type | Intermittent or steady | Laminated or turbulent |

| Governing Equations | Discrete element methods, Newton's laws | Navier-Stokes equations |

| Energy Dissipation | High, due to friction and inelastic collisions | Lower, dominated by viscosity |

| Density | Variable, depends on packing and voids | Constant or slightly variable |

| Compressibility | Generally compressible | Often incompressible (liquid), compressible (gas) |

| Applications | Pharmaceuticals, mining, agriculture | Hydraulics, aerodynamics, oceanography |

Introduction to Granular and Fluid Flow

Granular flow involves the movement of discrete solid particles such as sand, grains, or powders, exhibiting solid-like and fluid-like properties depending on the load and confinement. Fluid flow, characterized by the continuous motion of liquids or gases, follows well-defined principles governed by viscosity, pressure, and velocity fields described by the Navier-Stokes equations. Understanding granular flow requires consideration of particle interactions, size distribution, and frictional forces, contrasting with the continuum assumptions valid in fluid flow dynamics.

Fundamental Differences Between Granular and Fluid Flow

Granular flow consists of discrete solid particles interacting through contact forces and friction, whereas fluid flow involves continuous deformation of a medium with negligible shear strength. Granular materials exhibit behaviors such as jamming, dilatancy, and force chains, which are absent in fluid dynamics governed by Navier-Stokes equations. Unlike fluids, granular flow lacks constitutive relations based on viscosity and pressure fields, making modeling and prediction fundamentally distinct.

Physical Properties Affecting Each Flow Type

Granular flow is characterized by discrete solid particles interacting through friction, cohesion, and inelastic collisions, resulting in complex flow behaviors influenced by particle size, shape, and packing density. Fluid flow depends on continuous media properties such as viscosity, density, and surface tension, dictating laminar or turbulent regimes. The physical properties like grain stiffness and interstitial fluid presence differentiate granular flow from fluid flow, affecting their respective momentum transfer and energy dissipation mechanisms.

Governing Equations and Mathematical Models

Granular flow is governed by discrete element methods (DEM) that model particle interactions through Newton's laws and contact forces, emphasizing collision and friction, whereas fluid flow follows continuum mechanics described by Navier-Stokes equations accounting for viscosity and pressure fields. Mathematical models for granular flow often incorporate constitutive relations for stress based on particle packing and shear rates, contrasting with fluid flow models that use constitutive equations like the Newtonian or non-Newtonian fluid assumptions. Numerical simulations for granular media require coupling between particle dynamics and continuum fields in multiphase flows, differing fundamentally from single-phase fluid simulations relying primarily on partial differential equations of momentum and mass conservation.

Flow Regimes in Granular Versus Fluid Systems

Flow regimes in granular systems differ significantly from fluid flow due to particle interactions and discrete nature, exhibiting solid-like, liquid-like, and gas-like states based on particle concentration and velocity. Granular flow regimes include dense, collisional, and kinetic stages, influenced by factors such as particle size, shape, and inter-particle friction, whereas fluid flows are often characterized by laminar, transitional, and turbulent regimes determined by Reynolds number. Understanding these distinctions aids in optimizing industrial processes like hopper discharge, sediment transport, and pneumatic conveying, where granular behavior diverges from classical fluid dynamics principles.

Influence of Particle Size and Shape

Particle size and shape critically influence granular flow behavior by affecting packing density, friction, and flowability, while in fluid flow these factors impact viscosity and turbulence differently. Larger or irregularly shaped particles increase inter-particle friction and reduce flow rate in granular materials, contrasting with fluid flow where particle dimensions primarily alter flow resistance and Reynolds number. Understanding these distinctions is essential for optimizing processes in materials handling, pharmaceuticals, and chemical engineering.

Applications in Mechanical Engineering

Granular flow and fluid flow exhibit distinct behaviors critical to mechanical engineering applications such as powder handling, bulk material transport, and hydraulic systems. Granular flow manages particulate materials in processes like hopper discharge, pharmaceutical tablet manufacturing, and additive manufacturing, where particle interactions and friction dominate. Fluid flow principles govern cooling systems, lubrication mechanics, and aerodynamic designs, emphasizing continuous media properties and viscosity for efficient energy transfer and heat dissipation.

Experimental Techniques for Flow Analysis

Experimental techniques for analyzing granular flow often include Particle Image Velocimetry (PIV) and discrete element methods (DEM) to capture particle motion and interactions, while fluid flow analysis frequently relies on Laser Doppler Anemometry (LDA) and Computational Fluid Dynamics (CFD) for velocity field measurements and flow visualization. Granular flow experiments emphasize tracking individual particle dynamics and force chains, contrasting with fluid flow methods that focus on continuum properties like pressure and velocity gradients. High-speed imaging and tomographic reconstruction are pivotal in both domains for resolving complex flow patterns and validating numerical models.

Common Challenges and Limitations

Granular flow and fluid flow share challenges such as turbulence modeling and flow instability, but granular flow is further complicated by particle interactions, friction, and inelastic collisions that are absent in fluids. Unlike continuous fluid flow governed by Navier-Stokes equations, granular flow requires discrete element methods to capture heterogeneous particle dynamics and jamming phenomena. Limitations in computational resources and measurement techniques restrict accurate prediction of granular behavior under varying shear rates and packing densities.

Future Research Directions in Granular and Fluid Flow

Future research in granular and fluid flow emphasizes advanced computational modeling integrating discrete element methods with continuum fluid dynamics to capture complex interactions in multiphase systems. Investigations into non-Newtonian fluid behavior coupled with granular media under varying stress and shear conditions aim to improve predictive accuracy for industrial processes such as pharmaceuticals and geotechnical engineering. Emerging techniques leveraging machine learning and high-resolution imaging focus on real-time monitoring and control of flow regimes, enhancing efficiency and safety in pipeline transport and additive manufacturing.

Discrete Element Method (DEM)

Discrete Element Method (DEM) simulates granular flow by modeling individual particle interactions and contact forces, contrasting fluid flow models that treat fluids as continuous media governed by Navier-Stokes equations.

Continuum mechanics

Granular flow exhibits discrete particle interactions and nonlinear contact forces distinct from fluid flow's continuous stress-strain relationships modeled by continuum mechanics.

Rheology

Granular flow exhibits complex rheological behavior characterized by yield stress and shear-thickening, contrasting with fluid flow's continuous viscosity variations governed by Newtonian or non-Newtonian principles.

Shear banding

Shear banding in granular flow occurs due to discrete particle interactions and localized deformation, contrasting with fluid flow where shear bands form from continuous viscosity variations in the fluid.

Interparticle collision

Interparticle collisions in granular flow significantly differ from fluid flow due to energy dissipation and frictional interactions that dominate particle dynamics.

Bingham plasticity

Granular flow exhibits characteristics similar to Bingham plasticity, where yield stress controls deformation, unlike Newtonian fluid flow which lacks a yield threshold.

Jamming transition

Granular flow exhibits a jamming transition characterized by a sudden loss of mobility and rigidity onset, unlike fluid flow which remains continuous and deformable under shear stress.

Arching effect

The arching effect in granular flow occurs when particles interlock and form stable vault-like structures that impede movement, unlike fluid flow where molecules slide past each other smoothly without obstruction.

Dense vs. dilute regimes

Granular flow in dense regimes exhibits solid-like behavior with enduring particle contacts, while dilute regimes resemble fluid flow dominated by binary collisions and kinetic theory.

Non-Newtonian behavior

Granular flow exhibits complex Non-Newtonian behavior characterized by shear thinning, yield stress, and rate-dependent viscosity unlike typical fluid flow which often follows Newtonian principles.

Granular flow vs fluid flow Infographic

njnir.com

njnir.com