Additive manufacturing builds components layer by layer, enabling complex geometries and material efficiency that traditional subtractive methods cannot easily achieve. Subtractive manufacturing involves removing material from a solid block, which often results in higher material waste but offers superior surface finish and dimensional accuracy. Choosing between these processes depends on part complexity, production volume, and material considerations specific to mechanical engineering applications.

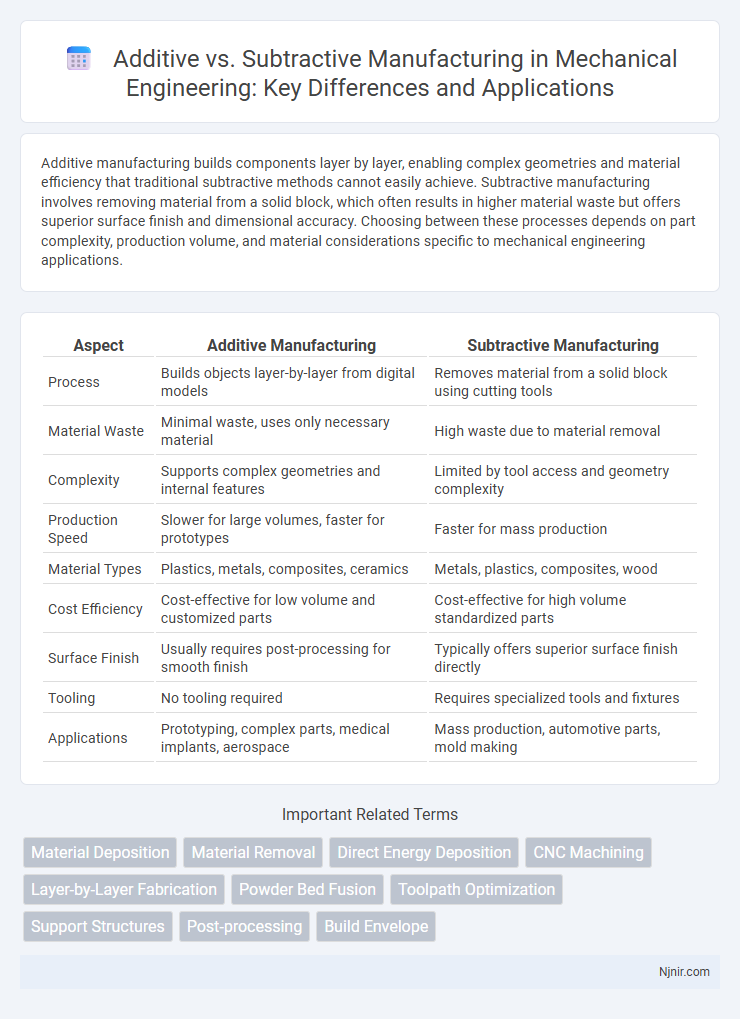

Table of Comparison

| Aspect | Additive Manufacturing | Subtractive Manufacturing |

|---|---|---|

| Process | Builds objects layer-by-layer from digital models | Removes material from a solid block using cutting tools |

| Material Waste | Minimal waste, uses only necessary material | High waste due to material removal |

| Complexity | Supports complex geometries and internal features | Limited by tool access and geometry complexity |

| Production Speed | Slower for large volumes, faster for prototypes | Faster for mass production |

| Material Types | Plastics, metals, composites, ceramics | Metals, plastics, composites, wood |

| Cost Efficiency | Cost-effective for low volume and customized parts | Cost-effective for high volume standardized parts |

| Surface Finish | Usually requires post-processing for smooth finish | Typically offers superior surface finish directly |

| Tooling | No tooling required | Requires specialized tools and fixtures |

| Applications | Prototyping, complex parts, medical implants, aerospace | Mass production, automotive parts, mold making |

Introduction to Manufacturing Processes

Additive manufacturing builds objects layer by layer from digital 3D models, enhancing design flexibility and material efficiency compared to traditional subtractive manufacturing, which removes material from solid blocks through machining processes. Additive processes include techniques like 3D printing, enabling complex geometries and rapid prototyping, while subtractive methods like milling and turning are valued for precision and surface finish in mass production. Understanding these manufacturing processes is critical for optimizing product development, reducing waste, and selecting appropriate fabrication methods based on design requirements and material properties.

Overview of Additive Manufacturing

Additive manufacturing builds objects layer by layer using digital 3D models, enabling complex geometries and minimal material waste. Common technologies include Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), and Stereolithography (SLA), widely used in aerospace, automotive, and medical industries. This process contrasts with subtractive manufacturing, which removes material from a solid block, often resulting in higher waste and longer production times.

Fundamentals of Subtractive Manufacturing

Subtractive manufacturing involves removing material from a solid block using cutting tools such as mills, lathes, and drills to create precise parts. This process relies on CNC machines to achieve high tolerance and surface finish, making it ideal for metals and hard plastics. Key parameters include cutting speed, feed rate, and tool geometry, which directly affect machining efficiency and part quality.

Key Material Considerations

Additive manufacturing primarily uses materials like thermoplastics, photopolymers, and metals such as titanium and stainless steel, emphasizing material deposition and fusion properties for layer-by-layer construction. Subtractive manufacturing relies heavily on solid blocks of metals, plastics, and composites, with key considerations including machinability, hardness, and grain structure to ensure precision and surface finish. Material waste is significantly lower in additive processes, while subtractive methods demand materials that withstand cutting forces without compromising integrity.

Design Flexibility and Complexity

Additive manufacturing enables unparalleled design flexibility by building objects layer by layer, allowing for intricate geometries, internal cavities, and complex structures that are impossible or cost-prohibitive in subtractive methods. Subtractive manufacturing, which removes material through machining or cutting, is limited by tool access and geometrical constraints, making it challenging to produce complex designs without additional assembly steps. This fundamental difference allows additive processes to innovate in product development with optimized lightweight structures and customized features.

Accuracy and Surface Finish

Additive manufacturing offers high precision in creating complex geometries with layer-by-layer material deposition, resulting in fine detail and minimal material waste. Subtractive manufacturing delivers superior surface finish and tighter tolerances due to controlled cutting and grinding processes, often requiring less post-processing for smooth surfaces. The accuracy of additive methods is improving with advancements in laser sintering and photopolymerization, but subtractive techniques currently excel in achieving consistently smoother finishes on metallic and high-hardness materials.

Production Speed and Scalability

Additive manufacturing enables rapid prototyping and small-batch production with high customization, offering faster turnaround times for complex designs. Subtractive manufacturing excels in high-volume production with consistent quality, benefiting from established scalability and automated processes. Production speed in additive methods depends on layer deposition rates, while subtractive processes leverage high-speed cutting tools for efficient large-scale output.

Cost Factors and Economic Impact

Additive manufacturing reduces material waste and lowers tooling expenses, resulting in significant cost savings for small production runs and customized products. Subtractive manufacturing often entails higher material costs and longer setup times but can be more economical for large-scale production due to faster cycle times and established processes. The economic impact of additive manufacturing includes accelerated product development and greater design flexibility, while subtractive methods benefit from economies of scale and mature supply chains.

Environmental and Sustainability Aspects

Additive manufacturing significantly reduces material waste by building objects layer by layer, using only the necessary amount of raw materials, which contrasts with subtractive manufacturing's method of cutting away excess material. The energy consumption in additive processes often results in lower carbon emissions compared to traditional subtractive techniques that require extensive machining and tooling. Furthermore, additive manufacturing promotes sustainability through the use of recyclable or biodegradable materials and supports localized production, minimizing transportation-related environmental impacts.

Future Trends in Additive and Subtractive Manufacturing

Future trends in additive manufacturing include advancements in multi-material printing, increased automation, and integration of AI-driven design optimization, which enhance production speed and customization capabilities. Subtractive manufacturing is evolving with the adoption of hybrid machining centers combining 3D printing and CNC milling to improve precision and reduce waste. Both methods are moving towards greater sustainability through energy-efficient technologies and recyclable materials, driving the industry's transition toward greener manufacturing solutions.

Material Deposition

Additive manufacturing builds objects by depositing material layer by layer, enhancing design complexity and material efficiency compared to subtractive manufacturing, which removes material through cutting or milling processes.

Material Removal

Additive manufacturing builds objects layer by layer by adding material, whereas subtractive manufacturing removes material through cutting, drilling, or milling to achieve the final shape.

Direct Energy Deposition

Direct Energy Deposition in additive manufacturing builds complex metal parts by melting materials layer-by-layer using focused energy sources, contrasting subtractive manufacturing which removes material from a solid block.

CNC Machining

CNC machining in subtractive manufacturing precisely removes material from a solid block, contrasting with additive manufacturing, which builds parts layer by layer for complex geometries and reduced waste.

Layer-by-Layer Fabrication

Additive manufacturing builds objects layer-by-layer through material deposition, while subtractive manufacturing removes material layer-by-layer from a solid block to achieve the final shape.

Powder Bed Fusion

Powder Bed Fusion, an additive manufacturing process, selectively fuses powdered material layer-by-layer using a high-energy source, contrasting with subtractive manufacturing that removes material from a solid block to create parts.

Toolpath Optimization

Toolpath optimization in additive manufacturing reduces material waste and build time by precisely controlling layer deposition, whereas in subtractive manufacturing it enhances cutting efficiency and surface finish by optimizing tool movements to minimize tool wear and machining time.

Support Structures

Additive manufacturing minimizes the need for extensive support structures by building objects layer-by-layer, whereas subtractive manufacturing often requires complex fixtures and supports to stabilize the material during machining.

Post-processing

Additive manufacturing typically requires minimal post-processing such as support removal and surface finishing, whereas subtractive manufacturing involves extensive post-processing steps like deburring, polishing, and heat treatment to achieve desired tolerances and surface quality.

Build Envelope

Additive manufacturing offers larger and more complex build envelopes with fewer size constraints compared to subtractive manufacturing, which is limited by tooling reach and machine bed dimensions.

Additive vs Subtractive manufacturing Infographic

njnir.com

njnir.com