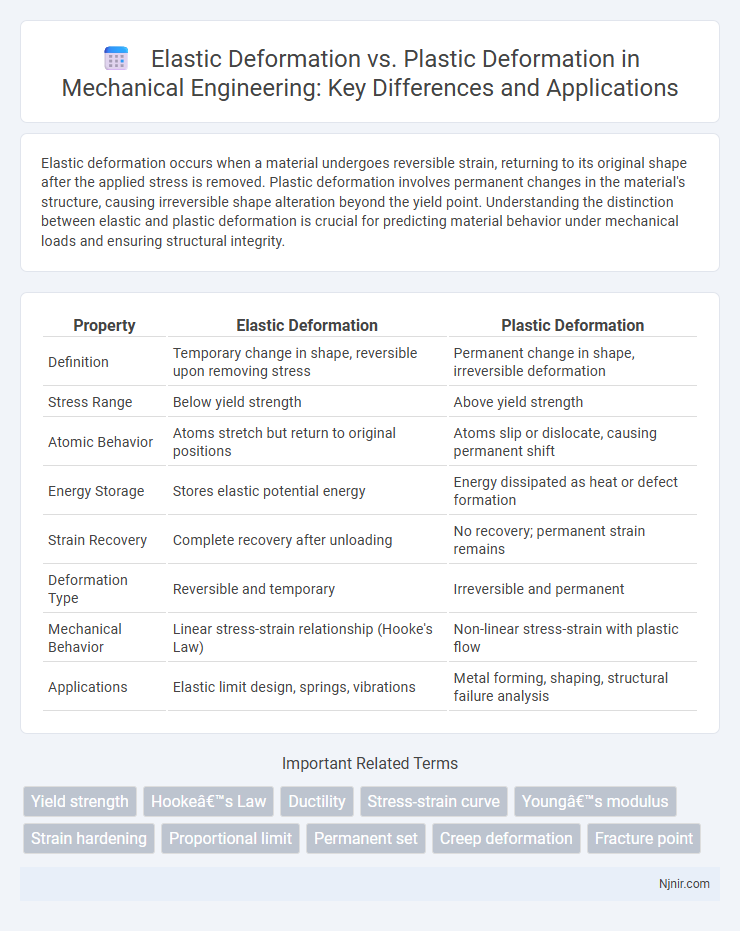

Elastic deformation occurs when a material undergoes reversible strain, returning to its original shape after the applied stress is removed. Plastic deformation involves permanent changes in the material's structure, causing irreversible shape alteration beyond the yield point. Understanding the distinction between elastic and plastic deformation is crucial for predicting material behavior under mechanical loads and ensuring structural integrity.

Table of Comparison

| Property | Elastic Deformation | Plastic Deformation |

|---|---|---|

| Definition | Temporary change in shape, reversible upon removing stress | Permanent change in shape, irreversible deformation |

| Stress Range | Below yield strength | Above yield strength |

| Atomic Behavior | Atoms stretch but return to original positions | Atoms slip or dislocate, causing permanent shift |

| Energy Storage | Stores elastic potential energy | Energy dissipated as heat or defect formation |

| Strain Recovery | Complete recovery after unloading | No recovery; permanent strain remains |

| Deformation Type | Reversible and temporary | Irreversible and permanent |

| Mechanical Behavior | Linear stress-strain relationship (Hooke's Law) | Non-linear stress-strain with plastic flow |

| Applications | Elastic limit design, springs, vibrations | Metal forming, shaping, structural failure analysis |

Introduction to Deformation in Materials

Deformation in materials occurs when external forces cause a change in shape or size, classified into elastic and plastic deformation. Elastic deformation is reversible, where the material returns to its original shape after the removal of stress, characterized by stress-strain behavior within the elastic limit. Plastic deformation involves permanent shape change as the material yields, often explained by dislocation movement in crystalline structures beyond the yield strength.

Defining Elastic Deformation

Elastic deformation refers to the reversible change in shape or size of a material when subjected to stress, where the material returns to its original form once the applied force is removed. This behavior is governed by the material's elastic modulus, indicating its ability to store and release strain energy without permanent alteration. Unlike plastic deformation, elastic deformation does not cause dislocation movement or permanent structural changes at the atomic level.

Understanding Plastic Deformation

Plastic deformation occurs when a material undergoes permanent shape change due to applied stress exceeding its yield strength, unlike elastic deformation which is reversible. This irreversible deformation results from dislocation movements within the crystal lattice of metals or the breaking of molecular bonds in polymers. Understanding plastic deformation is crucial for predicting material behavior under load, designing components to avoid failure, and improving materials through processes like work hardening.

Stress-Strain Curve Analysis

Elastic deformation occurs within the initial linear region of the stress-strain curve, where stress is proportional to strain, and the material returns to its original shape upon unloading. Plastic deformation begins at the yield point, marked by a deviation from linearity, resulting in permanent structural changes and permanent strain even after removing the applied stress. Stress-strain curve analysis highlights key parameters such as Young's modulus in the elastic region and yield strength at the onset of plastic deformation, critical for understanding material ductility and mechanical performance.

Key Differences Between Elastic and Plastic Deformation

Elastic deformation occurs when a material returns to its original shape after stress is removed, characterized by reversible atomic displacement within the elastic limit. Plastic deformation involves permanent shape change due to dislocation movement and slip, exceeding the material's yield strength. Elastic deformation stores strain energy, whereas plastic deformation dissipates energy through internal structural changes.

Microscopic Mechanisms of Deformation

Elastic deformation occurs when atomic bonds within a material stretch without breaking, allowing atoms to return to their original positions once the applied stress is removed. Plastic deformation involves the motion of dislocations, which are line defects in the crystal lattice that enable permanent atomic rearrangements and irreversible shape changes. The microscopic mechanisms underpinning plasticity include slip, twinning, and the interaction of dislocations with obstacles such as grain boundaries and impurities.

Factors Influencing Deformation Behavior

Material properties such as yield strength, ductility, and crystal structure significantly influence whether deformation is elastic or plastic. Temperature and strain rate also affect deformation behavior; higher temperatures and slower strain rates typically promote plastic deformation by enabling dislocation movement. Moreover, the presence of defects like dislocations, grain boundaries, and impurities alters the material's ability to undergo elastic recovery or permanent shape change.

Engineering Applications of Elastic and Plastic Deformation

Elastic deformation in engineering applications enables materials to return to their original shape after stress removal, critical in designing flexible components like springs and shock absorbers. Plastic deformation is utilized in metal forming processes such as forging, rolling, and extrusion, where permanent shape changes improve structural integrity and assembly fit. Understanding the stress-strain behavior ensures the selection of materials that balance elasticity for flexibility and plasticity for durability in mechanical systems.

Material Selection Based on Deformation Properties

Elastic deformation allows materials like steel and aluminum to return to their original shape after stress removal, making them ideal for applications requiring flexibility and resilience. Plastic deformation occurs when materials such as copper and lead undergo permanent shape changes under stress, suitable for processes like metal forming and fabrication. Selecting materials based on their elastic modulus, yield strength, and ductility ensures optimal performance in designs where deformation behavior is critical.

Conclusion: Implications for Mechanical Design

Elastic deformation allows materials to return to their original shape after stress, making it ideal for components requiring flexibility and repeated loading. Plastic deformation leads to permanent shape changes, which must be carefully managed in mechanical design to avoid failure or unwanted distortion. Understanding the balance between elastic and plastic behavior is crucial for optimizing material selection, structural integrity, and durability in engineering applications.

Yield strength

Yield strength defines the stress threshold at which a material transitions from elastic deformation, where it returns to its original shape, to plastic deformation, where permanent structural changes occur.

Hooke’s Law

Elastic deformation follows Hooke's Law, where strain is proportional to stress and reversible, while plastic deformation involves permanent, non-recoverable changes beyond the elastic limit.

Ductility

Ductility describes a material's ability to undergo plastic deformation without fracturing, distinguishing it from elastic deformation where the material returns to its original shape after stress removal.

Stress-strain curve

The stress-strain curve illustrates elastic deformation as the linear region where material returns to its original shape after stress removal, while plastic deformation occurs beyond the yield point, showing permanent strain and nonlinear behavior.

Young’s modulus

Elastic deformation reverses when stress is removed due to material's Young's modulus, while plastic deformation causes permanent shape change beyond the elastic limit.

Strain hardening

Strain hardening occurs during plastic deformation, where the material's dislocation density increases, enhancing strength and reducing ductility, unlike elastic deformation which is reversible and involves no permanent atomic rearrangement.

Proportional limit

The proportional limit marks the maximum stress at which elastic deformation occurs, beyond which plastic deformation begins as the material no longer returns to its original shape.

Permanent set

Permanent set occurs during plastic deformation when a material undergoes irreversible changes in shape after the applied stress exceeds its elastic limit.

Creep deformation

Creep deformation occurs when a material undergoes time-dependent plastic deformation under constant stress, contrasting with elastic deformation where the material returns to its original shape after stress removal.

Fracture point

Elastic deformation reverses after stress removal, whereas plastic deformation leads to permanent change and fracture occurs at the material's ultimate tensile strength beyond the elastic limit.

Elastic deformation vs plastic deformation Infographic

njnir.com

njnir.com