Conformal cooling offers enhanced thermal management by closely following the geometry of the mold, resulting in more uniform cooling and reduced cycle times compared to traditional straight-drilled cooling channels. This innovative approach improves part quality by minimizing warping and residual stresses while increasing the overall efficiency of the injection molding process. Traditional cooling methods often struggle with uneven heat dissipation, leading to longer production cycles and higher energy consumption.

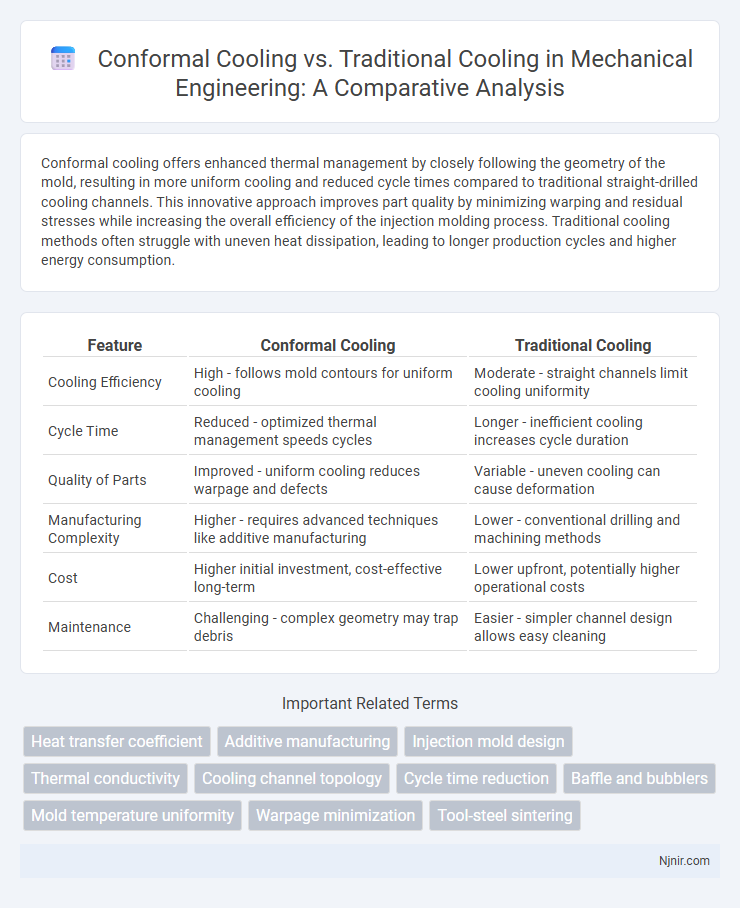

Table of Comparison

| Feature | Conformal Cooling | Traditional Cooling |

|---|---|---|

| Cooling Efficiency | High - follows mold contours for uniform cooling | Moderate - straight channels limit cooling uniformity |

| Cycle Time | Reduced - optimized thermal management speeds cycles | Longer - inefficient cooling increases cycle duration |

| Quality of Parts | Improved - uniform cooling reduces warpage and defects | Variable - uneven cooling can cause deformation |

| Manufacturing Complexity | Higher - requires advanced techniques like additive manufacturing | Lower - conventional drilling and machining methods |

| Cost | Higher initial investment, cost-effective long-term | Lower upfront, potentially higher operational costs |

| Maintenance | Challenging - complex geometry may trap debris | Easier - simpler channel design allows easy cleaning |

Introduction to Cooling Methods in Mechanical Engineering

Conformal cooling uses 3D-printed channels that follow the mold's geometry, enhancing heat dissipation efficiency compared to traditional straight-drilled cooling channels. This method reduces cycle times and improves part quality by maintaining uniform mold temperatures during injection molding processes. Traditional cooling often results in uneven cooling rates, leading to warpage and longer production cycles in mechanical engineering applications.

Fundamentals of Traditional Cooling Systems

Traditional cooling systems rely on straight-drilled channels within molds to circulate coolant, often resulting in uneven temperature distribution and longer cycle times in injection molding. These systems use conventional materials and designs that limit the proximity of cooling channels to the mold surface, reducing heat transfer efficiency. The fundamental challenge lies in maintaining uniform cooling while avoiding mold distortion and ensuring consistent part quality.

Principles of Conformal Cooling Technology

Conformal cooling technology utilizes advanced 3D printing techniques to create cooling channels that precisely follow the geometry of a mold, enhancing heat extraction efficiency and reducing cycle times compared to traditional straight drilled channels. This method optimizes thermal management by maintaining uniform mold temperatures, which improves part quality and minimizes warpage. The integration of conformal cooling channels leverages complex spatial curvatures impossible with conventional machining, enabling superior thermal conductivity and process stability in injection molding.

Design Differences: Conformal vs. Traditional Cooling Channels

Conformal cooling channels closely follow the contours of the molded part, enabling uniform temperature distribution and faster cooling cycles compared to traditional straight or drilled channels. Traditional cooling channels are typically linear and limited by machining constraints, resulting in uneven cooling and hotspots that can cause warping or longer cycle times. The design flexibility of conformal cooling, often achieved through additive manufacturing, allows for optimized thermal management that improves part quality and production efficiency.

Material Compatibility and Selection

Conformal cooling channels, typically produced using advanced additive manufacturing techniques, allow for the use of specialized materials such as maraging steel or high-grade tool steels, which offer superior thermal conductivity and corrosion resistance compared to traditional materials like aluminum or standard steel. Material selection for conformal cooling must consider compatibility with printing processes and the mold's operational environment, ensuring enhanced durability and consistent cooling performance under high thermal cycling. Traditional cooling systems often require machining constraints that limit material choices, thereby impacting thermal efficiency and long-term mold integrity.

Thermal Efficiency Comparison

Conformal cooling channels, designed to follow the geometry of the mold closely, enhance thermal efficiency by providing uniform heat extraction and reducing cycle times compared to traditional straight-drilled cooling channels. This optimized heat transfer results in improved temperature control and less thermal distortion, boosting product quality and mold lifespan. Studies show conformal cooling can increase cooling efficiency by up to 30%, significantly outperforming conventional cooling methods in complex injection-molded parts.

Manufacturing Process and Implementation

Conformal cooling channels are created using advanced additive manufacturing techniques such as selective laser melting, enabling complex internal geometries that closely follow mold contours for enhanced thermal efficiency. Traditional cooling systems rely on conventional machining processes like drilling, which limit channel placement and often result in uneven cooling and longer cycle times. Implementing conformal cooling demands integration of 3D printing technology and design optimization software, whereas traditional cooling involves more straightforward, but less flexible, manufacturing workflows.

Cost Analysis and Return on Investment

Conformal cooling systems typically incur higher upfront costs due to advanced manufacturing techniques like 3D printing, but they significantly reduce cycle times and improve product quality, resulting in lower operational expenses. In contrast, traditional cooling methods have lower initial investment but often lead to longer cooling cycles and increased scrap rates, raising overall production costs over time. The return on investment (ROI) for conformal cooling usually surpasses traditional systems within a shorter period, driven by enhanced efficiency and reduced downtime in high-volume manufacturing environments.

Common Applications in Industry

Conformal cooling is widely used in injection molding for complex geometries, aerospace components, and high-precision automotive parts, offering superior heat transfer efficiency compared to traditional straight-drilled cooling channels. Traditional cooling remains prevalent in large-scale manufacturing where simpler mold designs and cost efficiency are prioritized, such as in sheet metal forming and basic plastic products. Industries focused on rapid cycle times and intricate designs increasingly adopt conformal cooling to improve product quality and reduce tooling wear.

Future Trends in Cooling Technologies

Conformal cooling enhances thermal efficiency by closely following the mold geometry, resulting in faster cycle times and improved part quality compared to traditional straight-line cooling channels. Future trends emphasize integrating additive manufacturing to create more complex conformal channels, enabling precise temperature control and energy savings. Smart cooling systems with embedded sensors and AI-driven monitoring are emerging to optimize cooling performance in real-time for industrial applications.

Heat transfer coefficient

Conformal cooling channels significantly increase the heat transfer coefficient compared to traditional cooling methods by closely following the mold geometry, enhancing cooling efficiency and reducing cycle times.

Additive manufacturing

Additive manufacturing enables conformal cooling channels that precisely follow mold contours, significantly enhancing cooling efficiency and reducing cycle times compared to traditional straight-drilled cooling channels.

Injection mold design

Conformal cooling in injection mold design enhances heat dissipation efficiency and reduces cycle times by closely following the mold cavity contours, outperforming traditional straight-drilled cooling channels in uniform temperature control and part quality.

Thermal conductivity

Conformal cooling enhances heat dissipation by closely following mold contours, improving thermal conductivity and reducing cycle times compared to traditional cooling channels.

Cooling channel topology

Conformal cooling channels follow the precise contours of the mold, enhancing heat transfer efficiency and reducing cycle times compared to the straight, linear topology of traditional cooling channels.

Cycle time reduction

Conformal cooling reduces cycle time by up to 30% compared to traditional cooling methods through optimized heat dissipation and uniform temperature control.

Baffle and bubblers

Conformal cooling utilizes precisely designed baffles and bubblers to enhance heat dissipation efficiency and uniformity compared to the less targeted cooling channels found in traditional cooling systems.

Mold temperature uniformity

Conformal cooling achieves superior mold temperature uniformity by closely following the mold cavity contours, reducing hotspots and cycle times compared to traditional cooling methods.

Warpage minimization

Conformal cooling reduces warpage more effectively than traditional cooling by providing uniform temperature distribution and faster heat dissipation during the molding process.

Tool-steel sintering

Conformal cooling in tool-steel sintering enhances thermal management by evenly distributing coolant through complex geometries, reducing cycle times and improving tool lifespan compared to traditional cooling methods.

Conformal cooling vs traditional cooling Infographic

njnir.com

njnir.com