Hot rolling involves deforming metal above its recrystallization temperature, enhancing ductility and reducing internal stresses, while cold rolling occurs below this temperature, increasing strength and surface finish precision. Hot rolling typically results in larger grains and less precise tolerances, whereas cold rolling produces finer grain structures and superior dimensional accuracy. The choice between hot rolling and cold rolling depends on the desired mechanical properties and application requirements, balancing strength, surface quality, and formability.

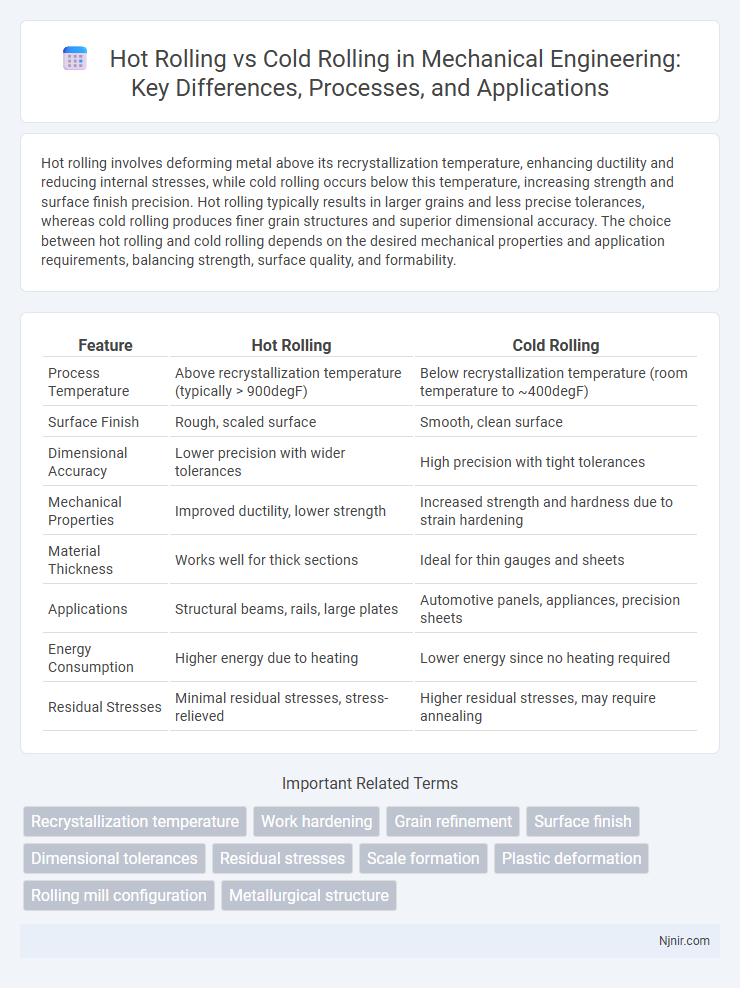

Table of Comparison

| Feature | Hot Rolling | Cold Rolling |

|---|---|---|

| Process Temperature | Above recrystallization temperature (typically > 900degF) | Below recrystallization temperature (room temperature to ~400degF) |

| Surface Finish | Rough, scaled surface | Smooth, clean surface |

| Dimensional Accuracy | Lower precision with wider tolerances | High precision with tight tolerances |

| Mechanical Properties | Improved ductility, lower strength | Increased strength and hardness due to strain hardening |

| Material Thickness | Works well for thick sections | Ideal for thin gauges and sheets |

| Applications | Structural beams, rails, large plates | Automotive panels, appliances, precision sheets |

| Energy Consumption | Higher energy due to heating | Lower energy since no heating required |

| Residual Stresses | Minimal residual stresses, stress-relieved | Higher residual stresses, may require annealing |

Introduction to Hot Rolling and Cold Rolling

Hot rolling involves processing metal above its recrystallization temperature, allowing easier shaping and improved material properties by reducing grain size and enhancing ductility. Cold rolling occurs below the recrystallization temperature, increasing strength and hardness through strain hardening while producing a smoother surface finish and tighter dimensional tolerances. Both methods are essential in metal forming industries, optimizing performance and application-specific characteristics.

Fundamental Principles of Metal Rolling

Hot rolling and cold rolling differ primarily in temperature conditions affecting metal deformation and microstructure. Hot rolling involves heating metal above its recrystallization temperature to enhance ductility and reduce strength, enabling significant shape changes with less force. Cold rolling occurs below recrystallization temperature, increasing strength through strain hardening while producing smoother surfaces and tighter dimensional tolerances.

Process Overview: Hot Rolling

Hot rolling involves heating metal above its recrystallization temperature, typically over 1700degF (926degC), to enable easier deformation and shaping. The process passes the heated metal through rollers to reduce thickness and form desired shapes, enhancing ductility and reducing internal stresses. This method is essential for producing large structural components and plates with improved grain structure and mechanical properties.

Process Overview: Cold Rolling

Cold rolling involves deforming metal sheets or strips below their recrystallization temperature, typically at room temperature, to enhance surface finish and dimensional accuracy. This process increases the strength and hardness through strain hardening while maintaining tighter tolerances and producing smoother surfaces compared to hot rolling. It is extensively used for producing thin gauges with improved mechanical properties suitable for precision applications in automotive, appliance, and metal fabrication industries.

Key Differences Between Hot and Cold Rolling

Hot rolling involves processing metal above its recrystallization temperature, resulting in improved ductility and reduced hardness, while cold rolling occurs below this temperature, leading to increased strength and a smoother surface finish. Hot rolling produces larger grain sizes and is typically used for creating structural steel shapes, whereas cold rolling refines grain size and enhances mechanical properties for applications requiring precise dimensions. The thermal and mechanical differences affect the final product's microstructure, dimensional accuracy, and surface characteristics.

Mechanical Properties Comparison

Hot rolling typically results in lower yield strength and tensile strength due to the recrystallization process that reduces dislocation density, leading to improved ductility and toughness. Cold rolling increases yield strength and tensile strength through strain hardening but reduces ductility and increases residual stresses. The choice between hot rolling and cold rolling depends on the desired balance of mechanical properties such as strength, hardness, and formability.

Surface Finish and Product Quality

Cold rolling produces a smoother, more uniform surface finish compared to hot rolling, which often results in scale formation and rough textures due to high temperatures. This enhanced surface quality in cold-rolled products leads to superior dimensional accuracy, improved mechanical properties, and better suitability for painting or coating applications. Hot-rolled materials generally exhibit lower surface precision but offer greater ductility and are more cost-effective for large structural components.

Applications in Industry

Hot rolling is widely used in industries requiring large-scale production of structural components like steel beams, rails, and plates due to its efficiency in shaping thick metal sections. Cold rolling is preferred in automotive, appliance, and aerospace industries for producing sheets and strips with superior surface finish, tighter tolerances, and enhanced mechanical properties. Both processes are essential in metal fabrication, with hot rolling mainly serving heavy industry and cold rolling catering to precision manufacturing.

Advantages and Disadvantages

Hot rolling offers advantages such as improved ductility and reduced internal stresses, making it ideal for shaping large metal pieces, but it results in a rough surface finish and less precise dimensions. Cold rolling provides superior surface finish, enhanced strength through strain hardening, and tighter dimensional tolerances, though it requires more energy and can introduce residual stresses and lower ductility. Choosing between hot rolling and cold rolling depends on application requirements for mechanical properties, surface quality, and dimensional accuracy.

Selecting the Appropriate Rolling Process

Selecting the appropriate rolling process depends on the desired mechanical properties and surface finish of the metal product. Hot rolling is ideal for large, thick materials requiring improved ductility and reduced residual stress, frequently used in structural steel production with temperatures above recrystallization point. Cold rolling is preferred for thinner sheets requiring superior surface quality, tighter tolerances, and increased strength through strain hardening, commonly used in automotive and appliance manufacturing.

Recrystallization temperature

Hot rolling occurs above the metal's recrystallization temperature, enabling grain refinement and reduced work hardening, while cold rolling occurs below this temperature, increasing strength through strain hardening without grain structure change.

Work hardening

Cold rolling induces significantly higher work hardening compared to hot rolling due to plastic deformation occurring below the metal's recrystallization temperature.

Grain refinement

Hot rolling promotes grain refinement through dynamic recrystallization at high temperatures, whereas cold rolling enhances grain refinement primarily by strain hardening and subsequent annealing.

Surface finish

Hot rolling produces a rough, scaled surface finish due to high-temperature oxidation, while cold rolling yields a smooth, polished surface with improved dimensional accuracy and surface quality.

Dimensional tolerances

Cold rolling achieves tighter dimensional tolerances than hot rolling due to its precise control over thickness and surface finish.

Residual stresses

Hot rolling significantly reduces residual stresses by allowing steel to recrystallize during processing, whereas cold rolling increases residual stresses due to plastic deformation below recrystallization temperature.

Scale formation

Hot rolling generates thick oxide scale due to high-temperature exposure, whereas cold rolling produces minimal or no scale formation because it is performed at or near room temperature.

Plastic deformation

Hot rolling involves plastic deformation of metals above their recrystallization temperature, allowing easier shape changes with reduced work hardening, whereas cold rolling occurs below this temperature, increasing strength and hardness through strain hardening during plastic deformation.

Rolling mill configuration

Hot rolling mills typically feature roughing and finishing stands designed for high-temperature deformation, while cold rolling mills use precise multi-stand configurations with work rolls and backup rolls optimized for low-temperature, high-accuracy sheet metal processing.

Metallurgical structure

Hot rolling refines the metallurgical structure by promoting recrystallization and grain growth, while cold rolling increases dislocation density and strain hardening, leading to a finer, more distorted grain structure.

hot rolling vs cold rolling Infographic

njnir.com

njnir.com