Magnetic bearings offer frictionless operation by using magnetic fields to levitate rotating shafts, which significantly reduces wear and maintenance compared to fluid bearings that rely on a lubricating film to support loads. Fluid bearings provide excellent damping and load-carrying capacity through a thin layer of liquid or gas but are susceptible to contamination and require continuous lubrication. Magnetic bearings excel in high-speed applications due to their minimal mechanical contact, while fluid bearings remain preferred in heavy-load scenarios where cost-effectiveness and simplicity are priorities.

Table of Comparison

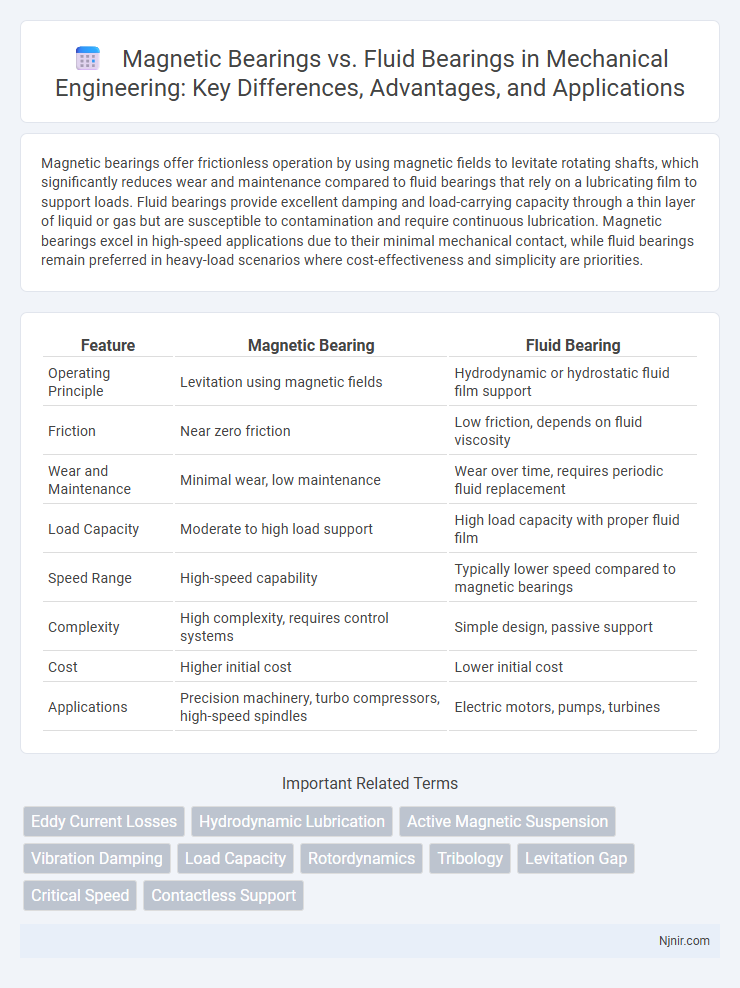

| Feature | Magnetic Bearing | Fluid Bearing |

|---|---|---|

| Operating Principle | Levitation using magnetic fields | Hydrodynamic or hydrostatic fluid film support |

| Friction | Near zero friction | Low friction, depends on fluid viscosity |

| Wear and Maintenance | Minimal wear, low maintenance | Wear over time, requires periodic fluid replacement |

| Load Capacity | Moderate to high load support | High load capacity with proper fluid film |

| Speed Range | High-speed capability | Typically lower speed compared to magnetic bearings |

| Complexity | High complexity, requires control systems | Simple design, passive support |

| Cost | Higher initial cost | Lower initial cost |

| Applications | Precision machinery, turbo compressors, high-speed spindles | Electric motors, pumps, turbines |

Introduction to Bearing Technologies in Mechanical Engineering

Magnetic bearings use electromagnetic forces to levitate the rotor, eliminating physical contact and reducing friction, wear, and maintenance in high-speed machinery. Fluid bearings utilize a thin layer of lubricating fluid, such as oil or air, to support the rotating shaft, providing excellent damping and load capacity in various mechanical applications. Both technologies offer advanced solutions in mechanical engineering by enhancing precision, reliability, and operational efficiency compared to traditional rolling-element bearings.

Fundamentals of Magnetic Bearings

Magnetic bearings use electromagnetic forces to levitate and support rotating shafts without physical contact, reducing friction and wear compared to fluid bearings that rely on a thin layer of lubricant to separate surfaces. The fundamentals of magnetic bearings involve actively controlling magnetic fields through sensors and electromagnets to stabilize shaft position within a precise tolerance. This contactless operation enables higher rotational speeds, improved reliability, and eliminates contamination risk inherent to fluid bearings.

Fundamentals of Fluid Bearings

Fluid bearings operate by maintaining a thin film of pressurized lubricant between the bearing surfaces, which reduces friction and wear while supporting heavy loads. These bearings rely on hydrodynamic principles, where the relative motion of surfaces creates pressure in the lubricant, enabling near-frictionless rotation without physical contact. Compared to magnetic bearings, fluid bearings provide high load capacity and damping, but are more susceptible to lubricant degradation and require continuous lubrication supply and maintenance.

Key Performance Differences: Magnetic vs Fluid Bearings

Magnetic bearings provide contactless support using electromagnetic fields, resulting in minimal friction and wear, which enhances efficiency and longevity compared to fluid bearings that rely on a thin film of lubricant, causing higher friction and maintenance requirements. Magnetic bearings offer superior precision and stability, enabling higher rotational speeds and better dynamic response, whereas fluid bearings are more susceptible to performance degradation due to lubricant contamination or viscosity changes. Energy consumption is generally lower in magnetic bearings, while fluid bearings benefit from simpler design and lower initial costs.

Load Capacity and Stability Comparison

Magnetic bearings offer higher load capacity and excellent stability due to their active control and lack of physical contact, enabling operation at high speeds with minimal friction and wear. Fluid bearings provide robust load capacity supported by a thin film of lubricant that distributes pressure evenly, ensuring smooth operation and damping vibrations, but they are typically less stable under variable load and speed conditions. The choice between magnetic and fluid bearings depends on application requirements, with magnetic bearings favored for precision and high-speed stability, while fluid bearings are preferred for cost-effective, moderate speed, and load scenarios.

Energy Efficiency and Power Consumption

Magnetic bearings offer superior energy efficiency due to virtually zero mechanical friction, significantly reducing power consumption compared to fluid bearings that rely on a lubricating film causing viscous drag. Fluid bearings consume more energy to maintain their fluid film and overcome friction, especially under high load or speed conditions. The low friction and contactless operation of magnetic bearings make them ideal for applications demanding minimal energy loss and optimized power usage.

Maintenance, Reliability, and Lifespan

Magnetic bearings offer low maintenance requirements due to their contactless operation, significantly reducing wear and extending lifespan compared to fluid bearings that depend on a continuous lubricating film prone to contamination and degradation. Reliability in magnetic bearings is enhanced by advanced control systems minimizing mechanical failures, whereas fluid bearings may suffer from reduced reliability caused by lubrication breakdown and bearing surface damage. Lifespan of magnetic bearings typically surpasses fluid bearings because they avoid physical contact and friction, whereas fluid bearings face limitations from lubricant fatigue and potential overheating issues.

Applications: Where Magnetic and Fluid Bearings Excel

Magnetic bearings excel in high-speed, precision applications such as turbines, compressors, and vacuum environments due to their contactless operation, which reduces friction and wear. Fluid bearings are ideal for heavy-load, low-speed machinery like large electric motors, pumps, and turbines, where their ability to support significant loads and dampen vibrations enhances reliability. Both bearing types are chosen based on application demands, with magnetic bearings favored for maintenance-free operation and fluid bearings for cost-effective load support in industrial settings.

Cost Considerations and Economic Viability

Magnetic bearings typically have higher initial costs due to advanced materials and complex control systems, but they offer lower maintenance expenses and longer lifespan, enhancing economic viability in high-performance applications. Fluid bearings generally present lower upfront investments and simpler designs, yet incur ongoing costs related to lubrication, cooling, and wear, which can affect total cost of ownership. Evaluating cost considerations requires analyzing application-specific factors such as load capacity, operational speed, and maintenance schedules to determine the most economically viable solution.

Future Trends and Innovations in Bearing Technology

Magnetic bearings are advancing with developments in active control systems and integration of smart sensors for predictive maintenance, offering near-frictionless operation and extended lifespan in high-speed machinery. Fluid bearings benefit from innovations in nano-lubricants and micro-textured surfaces that enhance load capacity and reduce energy loss in automotive and aerospace applications. The convergence of AI-driven monitoring and materials science is driving breakthroughs in both technologies, enabling more efficient, reliable, and sustainable bearing solutions for future industrial demands.

Eddy Current Losses

Magnetic bearings exhibit significantly lower eddy current losses compared to fluid bearings, enhancing energy efficiency and operational stability in high-speed rotating machinery.

Hydrodynamic Lubrication

Hydrodynamic lubrication in fluid bearings generates a full fluid film that supports loads and reduces friction, while magnetic bearings use electromagnetic forces to levitate the rotor, eliminating contact and lubrication needs.

Active Magnetic Suspension

Active Magnetic Suspension systems utilize magnetic bearings for frictionless, high-precision rotor control, outperforming fluid bearings by eliminating lubrication needs and reducing maintenance.

Vibration Damping

Magnetic bearings provide superior vibration damping compared to fluid bearings by actively controlling rotor position using electromagnetic forces, resulting in reduced mechanical contact and enhanced stability.

Load Capacity

Magnetic bearings generally offer higher load capacity and precision compared to fluid bearings, which are limited by lubricant viscosity and pressure constraints.

Rotordynamics

Magnetic bearings provide active control and reduced friction improving rotordynamics stability, while fluid bearings rely on hydrodynamic films offering damping but with higher friction and potential for fluid-induced instabilities.

Tribology

Magnetic bearings offer near-frictionless operation with negligible wear, significantly reducing tribological issues compared to fluid bearings, which rely on a lubricating film prone to degradation and wear under high loads.

Levitation Gap

Magnetic bearings maintain a precise levitation gap using electromagnetic forces for contactless rotor suspension, whereas fluid bearings rely on a thin fluid film to support the rotor, resulting in a variable levitation gap dependent on fluid pressure and viscosity.

Critical Speed

Magnetic bearings maintain stability and prevent contact at critical speeds by using electromagnetic forces, while fluid bearings rely on a pressurized lubricant film that can be less effective and prone to instability near critical speeds.

Contactless Support

Magnetic bearings provide contactless support through electromagnetic fields, reducing friction and wear compared to fluid bearings that rely on a thin film of lubricant for partial contactless operation.

Magnetic bearing vs fluid bearing Infographic

njnir.com

njnir.com