Hydraulic actuation provides higher force output and precise control in mechanical engineering applications compared to pneumatic actuation, making it ideal for heavy-duty tasks. Pneumatic systems offer faster response times and cleaner operation with compressed air, suitable for lighter loads and environments requiring minimal contamination. Both actuation types have distinct advantages, with hydraulic actuation excelling in power density and pneumatic actuation favored for simplicity and cost-effectiveness.

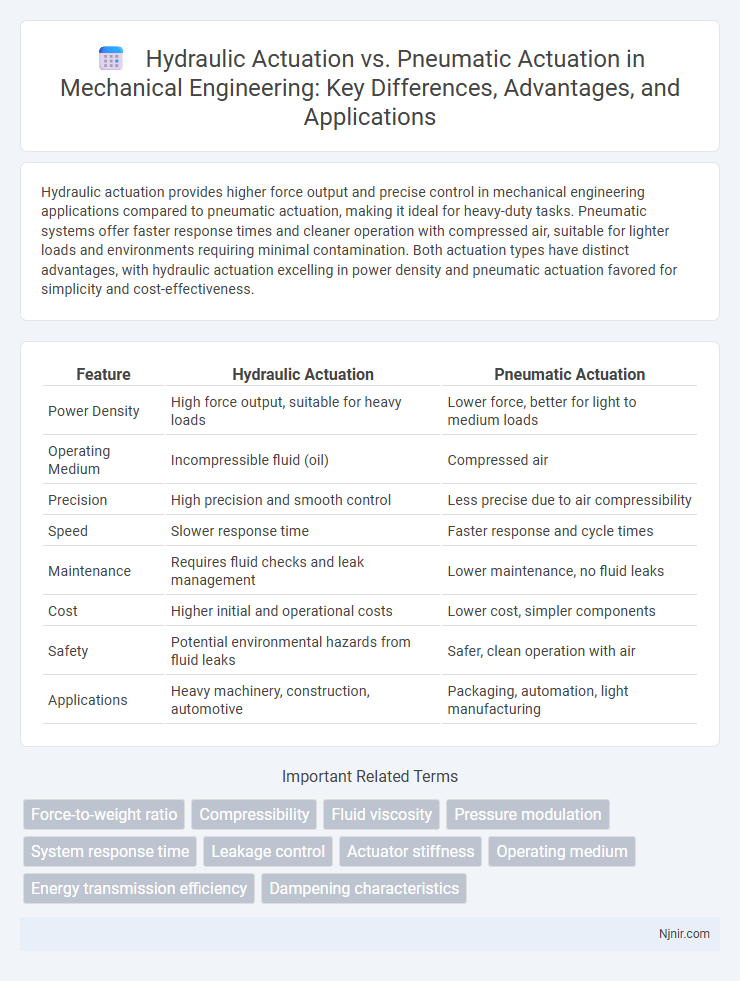

Table of Comparison

| Feature | Hydraulic Actuation | Pneumatic Actuation |

|---|---|---|

| Power Density | High force output, suitable for heavy loads | Lower force, better for light to medium loads |

| Operating Medium | Incompressible fluid (oil) | Compressed air |

| Precision | High precision and smooth control | Less precise due to air compressibility |

| Speed | Slower response time | Faster response and cycle times |

| Maintenance | Requires fluid checks and leak management | Lower maintenance, no fluid leaks |

| Cost | Higher initial and operational costs | Lower cost, simpler components |

| Safety | Potential environmental hazards from fluid leaks | Safer, clean operation with air |

| Applications | Heavy machinery, construction, automotive | Packaging, automation, light manufacturing |

Introduction to Actuation Systems

Hydraulic actuation systems utilize incompressible fluid to generate high force and precise control, making them ideal for heavy-duty industrial applications such as construction and manufacturing equipment. Pneumatic actuation systems rely on compressed air, offering faster response times and cleaner operation suited for lighter loads and automation tasks in food processing and packaging industries. Both systems convert energy into mechanical motion but differ significantly in pressure capacity, maintenance requirements, and operational efficiency.

Fundamentals of Hydraulic Actuation

Hydraulic actuation relies on incompressible fluid to transmit force through a closed system, providing precise and powerful motion control in various industrial applications. Key components include the hydraulic pump, actuator, valves, and fluid reservoir, which work together to convert fluid pressure into mechanical energy. This technology enables high force density and smooth operation, making it ideal for heavy-duty machinery and precision equipment.

Principles of Pneumatic Actuation

Pneumatic actuation operates by using compressed air to generate mechanical motion, relying on the principles of gas compressibility and airflow control. The system controls air pressure and flow through valves and actuators to create linear or rotary motion, offering rapid response and clean operation. This contrasts with hydraulic actuation, which uses incompressible fluids for higher force output but typically slower response times.

Comparative Analysis: Hydraulic vs Pneumatic

Hydraulic actuation offers higher force output and precise control due to incompressible fluid, making it ideal for heavy-duty applications requiring strong, stable motion. Pneumatic actuation uses compressed air, providing faster response times and simpler system design, but it has lower force capacity and less accuracy due to air compressibility. Hydraulic systems generally demand more maintenance and cost more upfront, while pneumatic systems are more cost-effective and cleaner, especially suitable for environments needing rapid, repetitive motion.

Efficiency and Power Output

Hydraulic actuation delivers higher efficiency and greater power output compared to pneumatic actuation due to the incompressibility of hydraulic fluid, enabling precise control and sustained force. Pneumatic systems, relying on compressed air, exhibit lower efficiency because of air compressibility and energy losses during compression and expansion. Hydraulic actuators are preferred in applications requiring high force and precise control, while pneumatic actuators suit lighter loads and faster cycles with lower power demands.

Application Areas in Mechanical Engineering

Hydraulic actuation is commonly used in heavy machinery, such as construction equipment, industrial presses, and aerospace controls, where high force and precise control are crucial. Pneumatic actuation finds applications in automation systems, packaging, and assembly lines due to its speed, cleanliness, and suitability for repetitive motion tasks. Mechanical engineering sectors leverage hydraulics for load-intensive operations and pneumatics for lightweight, rapid movement applications.

Control Precision and Responsiveness

Hydraulic actuation offers superior control precision due to its incompressible fluid, enabling fine-tuned movements and consistent force output, making it ideal for applications requiring exact positioning. Pneumatic actuation, relying on compressible air, exhibits faster responsiveness but suffers from lower precision and more variability in movement control. Advanced valve designs and feedback systems can enhance pneumatic responsiveness, yet hydraulic systems typically maintain better stability and smoother performance under variable loads.

Maintenance and Reliability Factors

Hydraulic actuation systems typically require more rigorous maintenance due to fluid contamination risks and potential for leaks, impacting long-term reliability if not properly managed. Pneumatic actuation, using compressed air, offers simpler maintenance with fewer leak-related issues but may experience performance variability due to moisture and pressure fluctuations. Reliability in hydraulic systems is enhanced by robust seals and fluid filtration, whereas pneumatic systems benefit from regular air quality monitoring and moisture removal to maintain consistent operation.

Cost Considerations and Investment

Hydraulic actuation systems typically incur higher initial costs due to the complexity of components like pumps, valves, and fluid reservoirs, but they offer greater precision and force control for heavy-duty applications. Pneumatic actuation tends to be more cost-effective upfront with simpler, less expensive equipment and lower maintenance costs, making it suitable for lighter, high-speed operations. Long-term investment decisions should weigh the total cost of ownership, including energy consumption, durability, and system efficiency, to determine the best fit for specific industrial needs.

Future Trends in Actuation Technologies

Future trends in actuation technologies emphasize advanced hydraulic systems featuring increased energy efficiency and precise control through smart sensors and AI integration. Pneumatic actuation is evolving with enhanced lightweight materials and digital monitoring for improved responsiveness and reduced maintenance. Hybrid electro-hydraulic and electro-pneumatic actuators are gaining traction, combining the strengths of both systems to meet the demands of automation and Industry 4.0 applications.

Force-to-weight ratio

Hydraulic actuation offers a significantly higher force-to-weight ratio compared to pneumatic actuation, enabling more powerful and compact system designs.

Compressibility

Hydraulic actuation provides precise control and higher force output due to the incompressibility of fluids, whereas pneumatic actuation experiences reduced accuracy and responsiveness because compressed air is highly compressible.

Fluid viscosity

Hydraulic actuation relies on incompressible, high-viscosity fluids for precise force control, whereas pneumatic actuation uses compressible, low-viscosity air, resulting in faster response but less precise control.

Pressure modulation

Hydraulic actuation provides precise and stable pressure modulation with high force density, while pneumatic actuation offers faster response but less accurate and more fluctuating pressure control due to compressibility of air.

System response time

Hydraulic actuation typically provides faster system response times than pneumatic actuation due to the incompressibility of fluids enabling quicker and more precise control.

Leakage control

Hydraulic actuation offers superior leakage control due to its incompressible fluid and robust sealing mechanisms compared to pneumatic actuation, which faces higher leakage risks from compressible air and less effective seals.

Actuator stiffness

Hydraulic actuation provides superior actuator stiffness compared to pneumatic actuation due to incompressible fluid dynamics, enhancing precision and load-bearing capacity in industrial applications.

Operating medium

Hydraulic actuation uses incompressible liquid, typically oil, for precise and powerful motion control, while pneumatic actuation relies on compressed air, offering faster response but with less force and precision.

Energy transmission efficiency

Hydraulic actuation delivers higher energy transmission efficiency than pneumatic actuation due to its incompressible fluid medium, resulting in less energy loss during power transfer.

Dampening characteristics

Hydraulic actuation provides superior dampening characteristics with smoother, more precise control and higher force density compared to pneumatic actuation, which tends to have faster response but increased compressibility and less precise dampening.

Hydraulic actuation vs Pneumatic actuation Infographic

njnir.com

njnir.com