Vibroacoustics studies sound generation and propagation due to vibrations in solid structures, emphasizing noise control in mechanical components. Aeroacoustics focuses on noise created by airflow and turbulence around vehicles and machinery, critical for optimizing aerodynamic design and reducing environmental noise pollution. Both disciplines integrate fluid dynamics and structural mechanics to enhance performance and reduce unwanted noise in engineering systems.

Table of Comparison

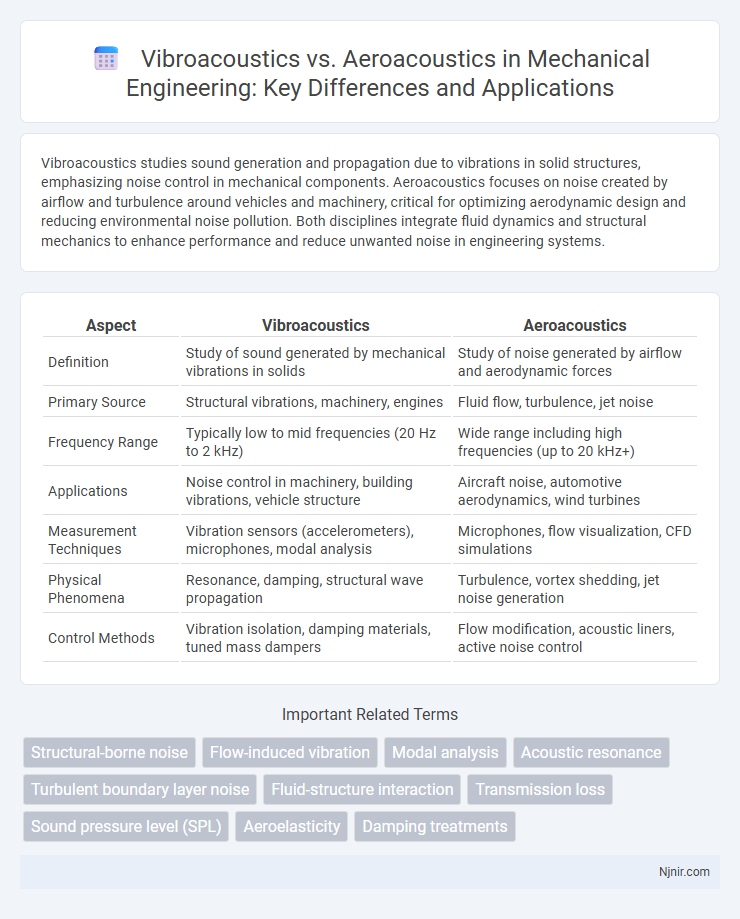

| Aspect | Vibroacoustics | Aeroacoustics |

|---|---|---|

| Definition | Study of sound generated by mechanical vibrations in solids | Study of noise generated by airflow and aerodynamic forces |

| Primary Source | Structural vibrations, machinery, engines | Fluid flow, turbulence, jet noise |

| Frequency Range | Typically low to mid frequencies (20 Hz to 2 kHz) | Wide range including high frequencies (up to 20 kHz+) |

| Applications | Noise control in machinery, building vibrations, vehicle structure | Aircraft noise, automotive aerodynamics, wind turbines |

| Measurement Techniques | Vibration sensors (accelerometers), microphones, modal analysis | Microphones, flow visualization, CFD simulations |

| Physical Phenomena | Resonance, damping, structural wave propagation | Turbulence, vortex shedding, jet noise generation |

| Control Methods | Vibration isolation, damping materials, tuned mass dampers | Flow modification, acoustic liners, active noise control |

Introduction to Vibroacoustics and Aeroacoustics

Vibroacoustics studies the interaction between structural vibrations and sound waves, emphasizing noise control and vibration reduction in mechanical systems. Aeroacoustics focuses on sound generation caused by turbulent fluid flows, such as airflow over aircraft wings or in jet engines, analyzing noise sources and propagation mechanisms. Both fields apply advanced computational models and experimental techniques to optimize acoustic performance in engineering applications.

Fundamental Principles of Vibroacoustics

Vibroacoustics investigates the interaction between structural vibrations and sound radiation, centered on the fundamental principles of vibration modes, resonance frequencies, and energy transfer between solid materials and surrounding fluid media. It examines how mechanical vibrations induce acoustic waves through coupling phenomena governed by wave propagation, impedance matching, and damping characteristics. Understanding modal analysis and frequency response functions is critical for designing systems that control noise and enhance sound quality in aerospace, automotive, and architectural applications.

Key Concepts in Aeroacoustics

Aeroacoustics studies noise generation from turbulent fluid motion and aerodynamic forces, emphasizing the interaction between airflow and solid surfaces. Key concepts include turbulent noise sources, vortex shedding, and sound propagation mechanisms in compressible flows. Understanding aeroacoustic phenomena enables the design of quieter aircraft, wind turbines, and HVAC systems by mitigating noise emissions through advanced computational fluid dynamics models.

Sources of Vibroacoustic Noise

Vibroacoustic noise primarily originates from mechanical vibrations transmitted through solid structures, including engines, compressors, and rotating machinery components. These vibrations induce sound waves within adjacent fluid media or structures, creating complex noise patterns characteristic of vibroacoustic phenomena. Common sources include structural resonances, panel vibrations, and machinery-induced oscillations, differentiating vibroacoustic noise from flow-induced aeroacoustic noise.

Generation and Propagation of Aeroacoustic Noise

Aeroacoustic noise is primarily generated by turbulent airflow interacting with solid surfaces, resulting in pressure fluctuations that propagate as sound waves through the surrounding fluid medium. This type of noise propagation involves complex mechanisms such as vortex shedding, turbulent mixing, and flow separation, which are absent in vibroacoustics where vibrations originate from structural dynamics. Vibroacoustics focuses on noise generated by mechanical vibrations transmitted through solid structures, whereas aeroacoustics deals with noise generated directly by the fluid flow and its interaction with physical boundaries.

Measurement Techniques in Vibroacoustics

Vibroacoustics measurement techniques primarily involve accelerometers, laser Doppler vibrometers, and modal analysis to capture structural vibrations and sound radiation. High-resolution sensors and advanced signal processing methods enable accurate identification of vibration modes and noise sources within mechanical systems. These techniques contrast with aeroacoustics measurements, which rely more on microphone arrays and flow visualization to study sound generated by fluid flow.

Experimental Methods in Aeroacoustics

Experimental methods in aeroacoustics primarily involve wind tunnel testing and microphone array measurements to capture noise generated by airflow around objects. Particle Image Velocimetry (PIV) and Laser Doppler Anemometry (LDA) enable detailed analysis of turbulent flow structures that contribute to sound generation. Unlike vibroacoustics, which emphasizes vibration measurement on solid structures, aeroacoustics experiments focus on fluid dynamics and aeroacoustic source characterization for noise reduction strategies.

Computational Modeling: Vibroacoustics vs Aeroacoustics

Computational modeling in vibroacoustics primarily involves finite element analysis (FEA) and boundary element methods (BEM) to simulate the interaction between structural vibrations and acoustic fields. Aeroacoustic modeling relies heavily on computational fluid dynamics (CFD) combined with acoustic analogies, such as Lighthill's analogy, to predict noise generation from turbulent airflow and aerodynamic surfaces. Techniques like hybrid CFD-CAA (computational aeroacoustics) are essential for capturing unsteady flow-induced noise, making aeroacoustic simulations computationally intensive compared to vibroacoustic models focused on solid-structure interactions.

Engineering Applications and Case Studies

Vibroacoustics focuses on analyzing and controlling vibrations and sound radiation in mechanical structures, essential in designing quieter engines, HVAC systems, and automotive components by mitigating noise and enhancing structural integrity. Aeroacoustics examines aerodynamic noise generation in fluid flows, critical in aircraft design, wind turbines, and high-speed trains to reduce noise pollution and improve performance. Case studies highlight vibroacoustic solutions in reducing engine vibration in automotive applications, while aeroacoustic research has led to optimized airfoil designs that minimize turbulence-induced noise in aerospace engineering.

Future Trends in Acoustic Engineering

Future trends in acoustic engineering highlight the increasing integration of vibroacoustics and aeroacoustics to enhance noise control and structural health monitoring in aerospace and automotive industries. Advancements in machine learning algorithms and sensor technologies enable more precise vibration and airflow noise prediction, driving innovations in quieter, more efficient designs. Sustainable materials and additive manufacturing methods are expected to play a crucial role in developing lightweight acoustic solutions with improved damping properties.

Structural-borne noise

Structural-borne noise in vibroacoustics primarily involves vibrations transmitted through solid structures, whereas in aeroacoustics, noise arises from turbulent airflow interacting with surfaces.

Flow-induced vibration

Flow-induced vibration in aeroacoustics primarily studies noise generated by fluid flow interacting with solid surfaces, while vibroacoustics focuses on the resulting structural vibrations and their acoustic radiation.

Modal analysis

Modal analysis in vibroacoustics examines structural vibration modes to predict noise and vibration, while in aeroacoustics it focuses on airflow-induced sound resonances and noise sources in fluid dynamics.

Acoustic resonance

Acoustic resonance in vibroacoustics involves vibration-induced sound amplification within structures, whereas in aeroacoustics, it pertains to airflow-driven pressure fluctuations causing resonant sound waves.

Turbulent boundary layer noise

Turbulent boundary layer noise in vibroacoustics arises from fluid-structure interactions generating vibrations, whereas in aeroacoustics it originates from turbulent airflow fluctuations causing aerodynamic sound emissions.

Fluid-structure interaction

Vibroacoustics studies sound generated by vibrations of solid structures, while aeroacoustics focuses on noise produced by fluid flow, with fluid-structure interaction playing a critical role in coupling vibrations and aerodynamic forces.

Transmission loss

Vibroacoustics typically exhibits higher transmission loss in structural-borne noise due to material damping, whereas aeroacoustics involves lower transmission loss as sound propagates through fluid media with minimal structural interaction.

Sound pressure level (SPL)

Vibroacoustics typically involves higher sound pressure levels (SPL) generated by vibrations transmitted through solid structures, whereas aeroacoustics primarily concerns sound produced by turbulent airflow with varying SPL depending on flow velocity and geometry.

Aeroelasticity

Aeroelasticity studies the interaction between aerodynamic forces and structural elasticity, crucial in aeroacoustics for predicting noise generated by fluid-structure interactions in aircraft and wind turbine designs.

Damping treatments

Damping treatments in vibroacoustics primarily target structural vibration reduction through viscoelastic materials, while in aeroacoustics, they focus on suppressing noise generated by turbulent airflow using porous liners and acoustic foams.

Vibroacoustics vs Aeroacoustics Infographic

njnir.com

njnir.com