Additive friction stir deposition offers enhanced grain refinement and reduced residual stresses compared to selective laser melting, resulting in superior mechanical properties and dimensional accuracy. It enables the fabrication of defect-free metal structures with improved microstructural homogeneity, making it ideal for complex aerospace components. Selective laser melting excels in producing intricate geometries but often requires extensive post-processing due to residual stresses and porosity.

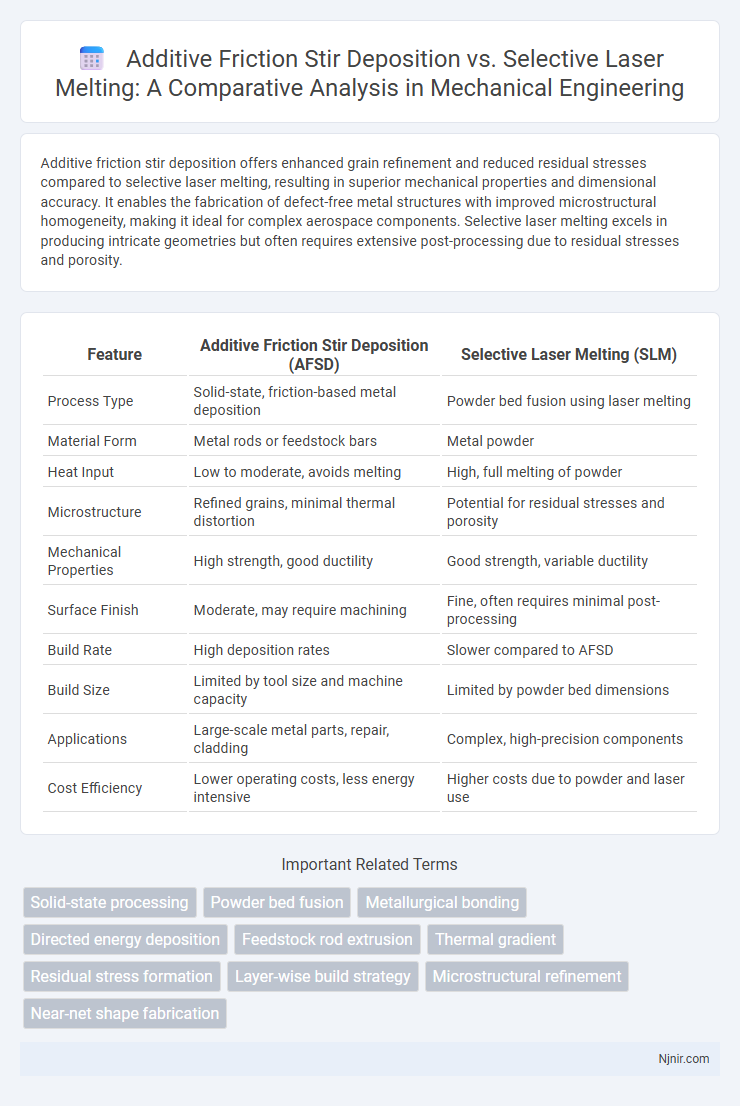

Table of Comparison

| Feature | Additive Friction Stir Deposition (AFSD) | Selective Laser Melting (SLM) |

|---|---|---|

| Process Type | Solid-state, friction-based metal deposition | Powder bed fusion using laser melting |

| Material Form | Metal rods or feedstock bars | Metal powder |

| Heat Input | Low to moderate, avoids melting | High, full melting of powder |

| Microstructure | Refined grains, minimal thermal distortion | Potential for residual stresses and porosity |

| Mechanical Properties | High strength, good ductility | Good strength, variable ductility |

| Surface Finish | Moderate, may require machining | Fine, often requires minimal post-processing |

| Build Rate | High deposition rates | Slower compared to AFSD |

| Build Size | Limited by tool size and machine capacity | Limited by powder bed dimensions |

| Applications | Large-scale metal parts, repair, cladding | Complex, high-precision components |

| Cost Efficiency | Lower operating costs, less energy intensive | Higher costs due to powder and laser use |

Introduction to Additive Friction Stir Deposition and Selective Laser Melting

Additive Friction Stir Deposition (AFSD) is an advanced solid-state additive manufacturing process that incrementally builds components by plastically deforming and depositing metal through frictional heat generated by a rotating tool. Selective Laser Melting (SLM) is a powder bed fusion technique that uses a high-power laser to fully melt and fuse metal powders layer-by-layer, enabling the fabrication of complex geometries with fine detail. AFSD offers benefits including reduced residual stresses and improved mechanical properties due to the absence of melting, while SLM provides high resolution and design flexibility through melting and rapid solidification.

Core Principles of Additive Friction Stir Deposition

Additive Friction Stir Deposition (AFSD) operates on a solid-state process where a rotating tool plasticizes metal feedstock, enabling layer-by-layer material consolidation without melting. This core principle reduces thermal distortion and residual stresses compared to Selective Laser Melting (SLM), which relies on powder bed fusion and localized melting using a laser beam. AFSD offers enhanced mechanical properties and microstructural control due to the absence of phase transformations inherent in the laser melting process of SLM.

Fundamentals of Selective Laser Melting Technology

Selective Laser Melting (SLM) technology utilizes a high-powered laser beam to selectively fuse metal powder layer by layer, enabling precise control over complex geometries and fine microstructures. Key fundamentals include powder bed preparation, laser scanning strategy, and thermal management to optimize melting and solidification, minimizing defects such as porosity and residual stresses. Compared to Additive Friction Stir Deposition, SLM offers higher resolution and material versatility through its powder-based, laser-driven melting process.

Material Compatibility and Processed Alloys

Additive friction stir deposition (AFSD) offers superior material compatibility with a wide range of alloys, including aluminum, magnesium, and titanium, due to its solid-state process that avoids melting and reduces thermal distortions. Selective laser melting (SLM) primarily processes high-strength steel, nickel-based superalloys, and titanium alloys, but is limited by powder characteristics and the risk of residual stresses caused by rapid melting and cooling. AFSD excels in joining dissimilar metals and processing large-scale components with improved microstructural integrity compared to the layer-by-layer melting approach in SLM.

Microstructural Characteristics: AFSD vs SLM

Additive friction stir deposition (AFSD) produces deposits with refined and equiaxed grain structures due to severe plastic deformation and dynamic recrystallization, resulting in enhanced mechanical properties and reduced defects compared to selective laser melting (SLM). In contrast, SLM typically forms columnar grains with microstructural anisotropy caused by rapid solidification and high thermal gradients, often leading to residual stresses and porosity. The lower thermal input in AFSD promotes better microstructural homogeneity and reduced residual stresses, while SLM offers higher geometric complexity but requires post-processing to alleviate microstructural defects.

Mechanical Properties Comparison

Additive friction stir deposition (AFSD) offers superior mechanical properties such as enhanced tensile strength and fatigue resistance compared to selective laser melting (SLM), due to its solid-state process that minimizes thermal stresses and grain coarsening. AFSD produces components with improved ductility and reduced residual stresses, making it advantageous for aerospace and automotive applications requiring high fatigue endurance. In contrast, SLM often results in higher hardness but increased brittleness and anisotropic microstructures, impacting the overall mechanical performance and potentially requiring post-processing heat treatments.

Surface Finish and Post-Processing Requirements

Additive Friction Stir Deposition (AFSD) typically produces parts with smoother surface finishes due to its solid-state material bonding, reducing porosity and thermal distortion commonly seen in Selective Laser Melting (SLM). SLM often requires extensive post-processing such as support removal, heat treatment, and surface polishing to address residual stresses and improve surface quality. AFSD minimizes post-processing efforts, making it advantageous for applications demanding near-net-shape parts with fine surface integrity.

Applications in Mechanical Engineering

Additive friction stir deposition (AFSD) is widely applied in mechanical engineering for producing large, defect-free metal components with superior mechanical properties, such as aerospace structural parts and automotive engine blocks. Selective laser melting (SLM) excels in fabricating intricate, high-precision metal parts with complex geometries, including turbine blades, biomedical implants, and customized tooling. Both techniques enhance lightweight design and material efficiency, but AFSD is preferred for large-scale, high-strength components while SLM is ideal for detailed, small-batch production.

Sustainability and Energy Efficiency

Additive friction stir deposition (AFSD) demonstrates superior sustainability and energy efficiency compared to selective laser melting (SLM) by utilizing solid-state material bonding, which reduces energy consumption and minimizes material waste. AFSD operates at lower temperatures, decreasing the carbon footprint associated with high-energy laser processes inherent in SLM. The enhanced material utilization and reduced post-processing in AFSD contribute significantly to eco-friendly additive manufacturing practices.

Future Trends and Technological Advancements

Additive friction stir deposition (AFSD) and selective laser melting (SLM) are advancing rapidly, with AFSD showing promise in producing defect-free, large-scale metal components with improved mechanical properties through solid-state processing. Future trends highlight AFSD's potential for energy-efficient, multi-material deposition and enhanced microstructural control, while SLM is evolving towards higher precision, faster build rates, and integration of real-time monitoring with AI-driven process optimization. Technological advancements in AFSD focus on tool design and alloy development, whereas SLM improvements concentrate on laser source innovation, powder management, and reducing residual stresses for aerospace and biomedical applications.

Solid-state processing

Additive friction stir deposition offers solid-state processing advantages over selective laser melting by minimizing thermal distortions and residual stresses in metal fabrication.

Powder bed fusion

Additive friction stir deposition offers solid-state layer bonding with minimal thermal distortion, contrasting with selective laser melting's powder bed fusion that achieves high-resolution, complex geometries through localized laser melting and rapid solidification.

Metallurgical bonding

Additive friction stir deposition achieves superior metallurgical bonding through solid-state joining with refined microstructures, whereas selective laser melting relies on melting and solidification processes that can introduce residual stresses and porosity.

Directed energy deposition

Directed energy deposition techniques like Additive Friction Stir Deposition offer superior material bonding and lower thermal distortion compared to Selective Laser Melting, enhancing mechanical properties in metal additive manufacturing.

Feedstock rod extrusion

Additive friction stir deposition utilizes feedstock rod extrusion to consolidate material through plastic deformation, offering superior microstructural control compared to the powder-based layer fusion process in selective laser melting.

Thermal gradient

Additive friction stir deposition exhibits a lower thermal gradient than selective laser melting, resulting in reduced residual stresses and improved microstructural homogeneity.

Residual stress formation

Additive friction stir deposition generates lower residual stresses than selective laser melting due to its solid-state process and reduced thermal gradients.

Layer-wise build strategy

Additive friction stir deposition uses a solid-state, layer-wise plastic deformation process for material bonding, while selective laser melting employs a layer-by-layer laser melting and fusion of powder particles.

Microstructural refinement

Additive friction stir deposition achieves superior microstructural refinement through intense plastic deformation and dynamic recrystallization, while selective laser melting relies on rapid solidification to produce fine microstructures with potential thermal-induced residual stresses.

Near-net shape fabrication

Additive friction stir deposition achieves near-net shape fabrication through solid-state material consolidation with minimal thermal distortion, while selective laser melting enables precise near-net shape creation via layer-by-layer powder fusion with higher thermal input.

Additive friction stir deposition vs Selective laser melting Infographic

njnir.com

njnir.com