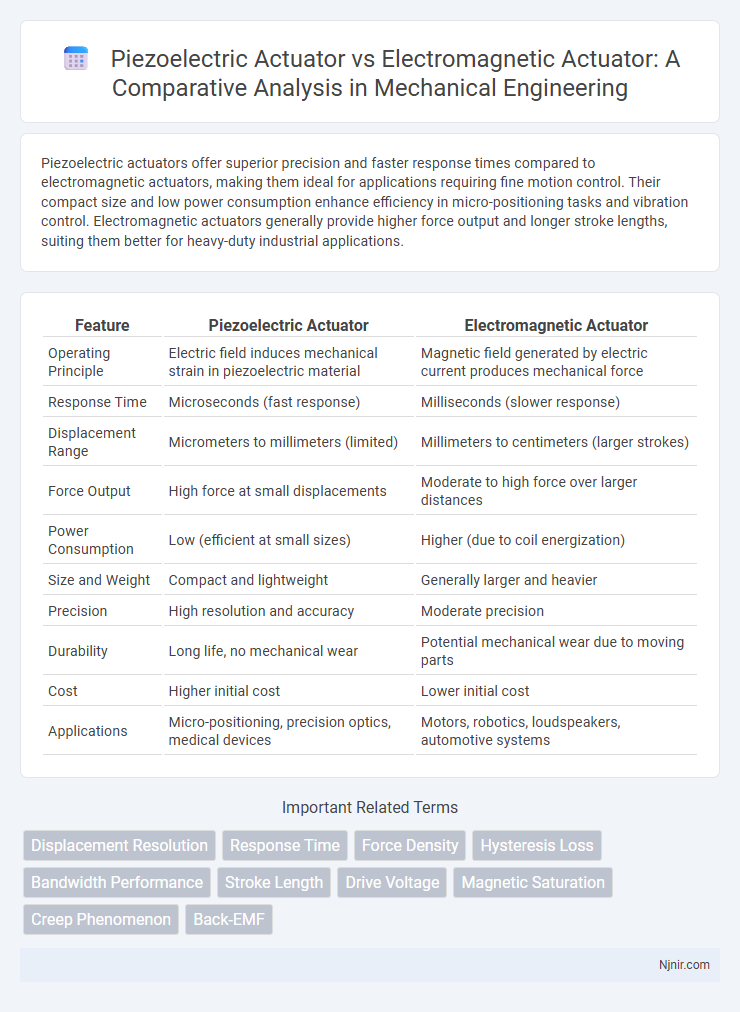

Piezoelectric actuators offer superior precision and faster response times compared to electromagnetic actuators, making them ideal for applications requiring fine motion control. Their compact size and low power consumption enhance efficiency in micro-positioning tasks and vibration control. Electromagnetic actuators generally provide higher force output and longer stroke lengths, suiting them better for heavy-duty industrial applications.

Table of Comparison

| Feature | Piezoelectric Actuator | Electromagnetic Actuator |

|---|---|---|

| Operating Principle | Electric field induces mechanical strain in piezoelectric material | Magnetic field generated by electric current produces mechanical force |

| Response Time | Microseconds (fast response) | Milliseconds (slower response) |

| Displacement Range | Micrometers to millimeters (limited) | Millimeters to centimeters (larger strokes) |

| Force Output | High force at small displacements | Moderate to high force over larger distances |

| Power Consumption | Low (efficient at small sizes) | Higher (due to coil energization) |

| Size and Weight | Compact and lightweight | Generally larger and heavier |

| Precision | High resolution and accuracy | Moderate precision |

| Durability | Long life, no mechanical wear | Potential mechanical wear due to moving parts |

| Cost | Higher initial cost | Lower initial cost |

| Applications | Micro-positioning, precision optics, medical devices | Motors, robotics, loudspeakers, automotive systems |

Introduction to Actuators in Mechanical Engineering

Piezoelectric actuators convert electrical energy into precise mechanical displacement using the deformation of piezoelectric crystals, offering high resolution and fast response times ideal for micro-positioning in mechanical engineering applications. Electromagnetic actuators rely on magnetic fields generated by electric currents to create mechanical motion, providing larger force and displacement capabilities suitable for general-purpose industrial automation. Both types play critical roles in actuator selection, balancing factors like force output, speed, accuracy, and application-specific requirements in mechanical systems design.

Fundamental Principles: Piezoelectric vs Electromagnetic Actuators

Piezoelectric actuators operate based on the direct piezoelectric effect, where certain materials generate mechanical strain in response to an applied electric field, enabling precise, high-frequency displacement at the nanoscale. Electromagnetic actuators function through Lorentz force principles, converting electrical current and magnetic fields into mechanical motion, suitable for larger displacements and higher forces. The fundamental distinction lies in the energy conversion mechanism: piezoelectric actuators rely on electro-mechanical coupling at the crystal lattice level, while electromagnetic actuators depend on magnetic field interactions with current-carrying conductors.

Structural Design and Material Composition

Piezoelectric actuators utilize ceramic materials like lead zirconate titanate (PZT) that deform under an electric field, enabling high-precision and rapid response in compact structures with minimal moving parts. Electromagnetic actuators rely on ferromagnetic cores and copper coils to generate motion through magnetic fields, resulting in larger and heavier assemblies capable of delivering significant force but with slower response times. The distinct material composition and structural design choices directly influence performance characteristics such as precision, speed, size, and force output in these actuators.

Working Mechanisms: How Each Actuator Functions

Piezoelectric actuators operate by converting electrical voltage into precise mechanical displacement through the deformation of piezoelectric crystals, enabling rapid, high-resolution movements ideal for micro-positioning applications. In contrast, electromagnetic actuators function by generating a magnetic field via an electric current that interacts with permanent magnets or coils, producing linear or rotational motion with higher force output and longer stroke lengths. These fundamental working mechanisms define their suitability for applications requiring either fine precision or greater power and range of motion.

Performance Characteristics and Response Times

Piezoelectric actuators offer high precision with response times in the microsecond range, making them ideal for applications requiring rapid, fine movements. Electromagnetic actuators provide greater force and longer stroke lengths but typically exhibit slower response times, usually in the millisecond range. The superior speed and accuracy of piezoelectric actuators contrast with the higher load capacity and robustness of electromagnetic actuators.

Power Consumption and Efficiency Comparison

Piezoelectric actuators exhibit significantly lower power consumption due to their ability to operate with minimal current, relying primarily on voltage-induced deformation of piezoelectric materials. In contrast, electromagnetic actuators consume more power because they require continuous current flow to generate magnetic fields for movement. Efficiency-wise, piezoelectric actuators achieve higher energy efficiency in precision applications by converting electrical energy directly into mechanical displacement without substantial thermal losses, while electromagnetic actuators often experience greater energy dissipation through heat and friction.

Precision, Accuracy, and Motion Control

Piezoelectric actuators deliver nanometer-level precision and rapid response times, making them ideal for ultra-fine positioning and high-resolution motion control. Electromagnetic actuators provide high force output and larger stroke lengths but typically exhibit lower accuracy and slower response compared to piezoelectric types. The inherent stiffness and minimal hysteresis of piezoelectric actuators enable superior repeatability and accuracy in precision applications, while electromagnetic actuators excel in applications requiring robust motion over longer distances.

Common Applications in Mechanical Systems

Piezoelectric actuators are commonly used in precision positioning systems, micro-electromechanical devices, and adaptive optics due to their high resolution and fast response. Electromagnetic actuators find widespread application in robotics, automotive systems, and industrial automation because of their high force output and durability. Both actuator types are integral in vibration control and sensor systems, each optimized for specific performance requirements in mechanical operations.

Challenges and Limitations of Both Technologies

Piezoelectric actuators face challenges such as limited displacement ranges and sensitivity to temperature variations, which affect precision and long-term stability. Electromagnetic actuators are constrained by factors including larger size, higher power consumption, and electromagnetic interference that can disrupt nearby electronic systems. Both technologies encounter trade-offs between force output, response speed, and energy efficiency, limiting their applications depending on specific performance requirements.

Future Trends and Innovations in Actuator Technology

Future trends in actuator technology emphasize miniaturization and enhanced precision, with piezoelectric actuators leading in high-frequency response and energy efficiency. Electromagnetic actuators are evolving through improved materials like soft magnetic composites and integrated sensors for real-time feedback and adaptive control. Innovations such as hybrid actuators combining piezoelectric and electromagnetic principles are poised to expand applications in robotics, aerospace, and medical devices.

Displacement Resolution

Piezoelectric actuators offer displacement resolution at the nanometer scale, significantly surpassing electromagnetic actuators, which typically achieve micrometer-level resolution.

Response Time

Piezoelectric actuators exhibit significantly faster response times, often in the microsecond range, compared to electromagnetic actuators which typically operate in the millisecond range.

Force Density

Piezoelectric actuators offer significantly higher force density compared to electromagnetic actuators due to their solid-state operation and direct electromechanical coupling.

Hysteresis Loss

Piezoelectric actuators exhibit significantly lower hysteresis loss compared to electromagnetic actuators, resulting in higher precision and energy efficiency in applications requiring fine displacement control.

Bandwidth Performance

Piezoelectric actuators offer significantly higher bandwidth performance, reaching up to several kilohertz, compared to electromagnetic actuators that typically operate below one kilohertz.

Stroke Length

Piezoelectric actuators typically offer shorter stroke lengths up to 100 micrometers, while electromagnetic actuators can achieve stroke lengths ranging from millimeters to several centimeters.

Drive Voltage

Piezoelectric actuators operate efficiently at low drive voltages typically ranging from 10 to 100 volts, whereas electromagnetic actuators usually require higher drive voltages between 12 and 48 volts for effective performance.

Magnetic Saturation

Piezoelectric actuators avoid magnetic saturation issues common in electromagnetic actuators, enabling precise control in high-field environments.

Creep Phenomenon

Piezoelectric actuators exhibit significant creep phenomena characterized by time-dependent strain under constant voltage, unlike electromagnetic actuators which generally display negligible creep due to their magnetically induced displacement mechanisms.

Back-EMF

Piezoelectric actuators generate displacement through electric charge without back-EMF, whereas electromagnetic actuators produce back-EMF proportional to the speed of motion, impacting control responsiveness and energy efficiency.

piezoelectric actuator vs electromagnetic actuator Infographic

njnir.com

njnir.com