Tribology studies the interaction of surfaces in relative motion, emphasizing friction, wear, and lubrication mechanisms to improve machine reliability. Lubrication engineering specifically focuses on designing and applying lubricants to reduce friction and wear between contacting surfaces. Understanding tribological principles enhances lubrication strategies, optimizing mechanical performance and extending component lifespan.

Table of Comparison

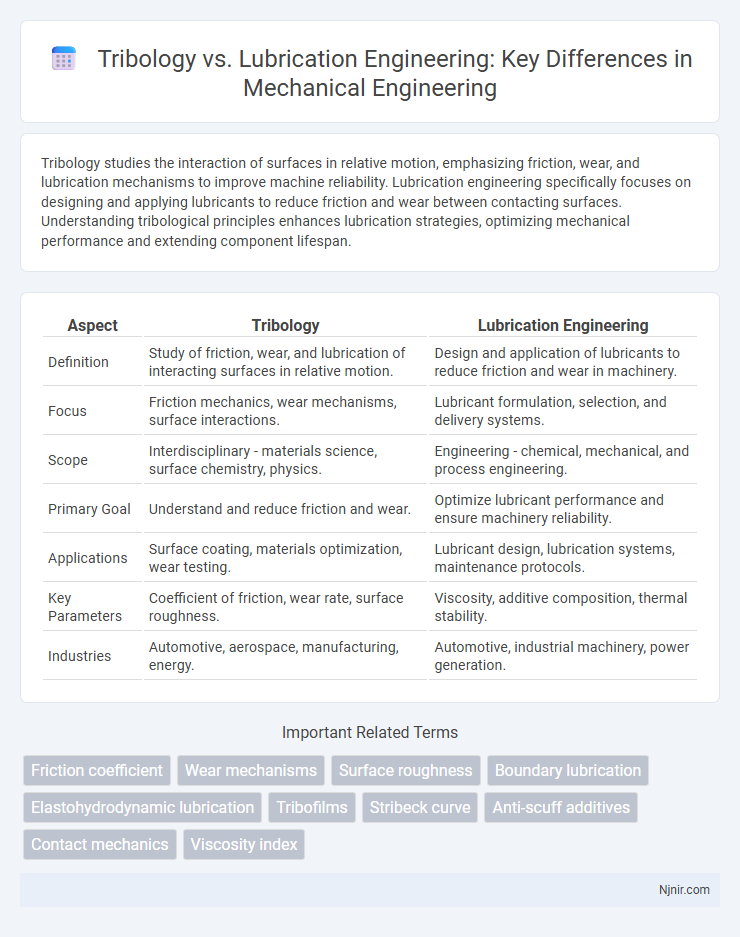

| Aspect | Tribology | Lubrication Engineering |

|---|---|---|

| Definition | Study of friction, wear, and lubrication of interacting surfaces in relative motion. | Design and application of lubricants to reduce friction and wear in machinery. |

| Focus | Friction mechanics, wear mechanisms, surface interactions. | Lubricant formulation, selection, and delivery systems. |

| Scope | Interdisciplinary - materials science, surface chemistry, physics. | Engineering - chemical, mechanical, and process engineering. |

| Primary Goal | Understand and reduce friction and wear. | Optimize lubricant performance and ensure machinery reliability. |

| Applications | Surface coating, materials optimization, wear testing. | Lubricant design, lubrication systems, maintenance protocols. |

| Key Parameters | Coefficient of friction, wear rate, surface roughness. | Viscosity, additive composition, thermal stability. |

| Industries | Automotive, aerospace, manufacturing, energy. | Automotive, industrial machinery, power generation. |

Introduction to Tribology and Lubrication Engineering

Tribology studies friction, wear, and lubrication of interacting surfaces in relative motion, crucial for enhancing machine reliability and efficiency. Lubrication engineering applies tribological principles to design effective lubricants and lubrication systems that reduce friction and prevent surface damage. Understanding tribology fundamentals enables engineers to optimize lubrication strategies, improve equipment lifespan, and minimize energy consumption.

Fundamental Principles of Tribology

Tribology is the scientific study of friction, wear, and lubrication between interacting surfaces in relative motion, focusing on understanding material properties and surface interactions at micro and nanoscale levels. Lubrication engineering applies these principles to design and optimize lubricants and lubrication systems that minimize friction and wear, improving machinery efficiency and lifespan. Fundamental principles of tribology include contact mechanics, surface topography, and the behavior of lubricants under various operating conditions.

Core Concepts in Lubrication Engineering

Lubrication engineering focuses on reducing friction, wear, and heat between interacting surfaces through the application of lubricants such as oils and greases. Core concepts include understanding lubricant properties, film formation, and the mechanisms of boundary, mixed, and hydrodynamic lubrication regimes. Effective lubrication engineering enhances machinery efficiency, lifespan, and reliability by optimizing lubricant selection, delivery, and maintenance practices.

Historical Development: Tribology vs Lubrication Engineering

Tribology, coined in the 1960s, encompasses the study of friction, wear, and lubrication across various materials and surfaces, evolving from ancient practices of reducing friction in machinery. Lubrication engineering, rooted in early industrial advancements, specifically focuses on the application and optimization of lubricants to enhance machinery performance and longevity. The historical development of tribology integrates interdisciplinary research, expanding beyond lubrication engineering's practical approach to address broader issues in material science and mechanical design.

Scope and Application Areas

Tribology encompasses the study of friction, wear, and lubrication across mechanical systems, focusing on understanding material interactions and surface phenomena to optimize performance and durability. Lubrication engineering, a subset of tribology, specifically deals with the design, selection, and application of lubricants and lubrication systems to reduce friction and wear in machinery. Application areas for tribology include automotive, aerospace, manufacturing, and biomedical implants, whereas lubrication engineering is crucial in industries like heavy machinery, power generation, and transportation where effective lubricant management is essential for reliability and efficiency.

Key Differences Between Tribology and Lubrication Engineering

Tribology encompasses the study of friction, wear, and lubrication of interacting surfaces in relative motion, focusing on the fundamental principles underlying surface interactions. Lubrication engineering specifically applies these principles to design and optimize lubricants and lubrication systems for reducing friction and wear in mechanical components. While tribology has a broader scope addressing material properties and contact mechanics, lubrication engineering targets practical solutions for enhancing machinery performance and reliability.

Interdisciplinary Roles in Mechanical Systems

Tribology and lubrication engineering intersect in analyzing and optimizing friction, wear, and lubrication within mechanical systems, enhancing machinery durability and efficiency. Tribology integrates materials science, surface chemistry, and mechanical engineering to understand interactions at contact interfaces, while lubrication engineering focuses on the design and application of lubricants to reduce friction and prevent component failure. Their interdisciplinary collaboration drives innovation in automotive, aerospace, and manufacturing sectors by improving component reliability and reducing maintenance costs.

Tribological Testing Methods vs Lubricant Evaluation Techniques

Tribological testing methods encompass wear and friction measurements under various operating conditions to analyze material interactions and surface degradation, including pin-on-disk, ball-on-flat, and reciprocating sliding tests. Lubricant evaluation techniques focus on assessing lubricant properties such as viscosity, film strength, thermal stability, and oxidation resistance using tests like ASTM D445 (kinematic viscosity), Four-Ball Wear Test (ASTM D4172), and Timken OK Load Test. Both disciplines employ advanced instrumentation including tribometers and rheometers to optimize performance and extend machinery lifespan through precise analysis of friction, wear, and lubrication efficacy.

Career Paths and Industry Demand

Tribology, the study of friction, wear, and lubrication, offers career paths in research, material science, and mechanical engineering with high demand in automotive, aerospace, and manufacturing industries. Lubrication engineering focuses on the application of lubricants to reduce wear and improve machinery efficiency, leading to roles in maintenance, reliability engineering, and industrial equipment design. Both fields experience strong industry demand driven by advancements in machinery performance, sustainability goals, and predictive maintenance technologies.

Future Trends in Tribology and Lubrication Engineering

Future trends in tribology and lubrication engineering emphasize the development of advanced nanomaterials and smart lubricants that enhance friction reduction and wear resistance. Integration of artificial intelligence and machine learning enables real-time monitoring and predictive maintenance, optimizing lubricant performance and system reliability. Sustainable and eco-friendly lubricants are increasingly prioritized to meet environmental regulations and support green manufacturing initiatives.

Friction coefficient

Tribology encompasses the study of friction, wear, and lubrication, while lubrication engineering specifically focuses on optimizing friction coefficients through the application of lubricants to minimize wear and energy loss.

Wear mechanisms

Tribology studies wear mechanisms including adhesion, abrasion, and fatigue in material contacts, while lubrication engineering designs lubricants and systems to minimize wear and friction in mechanical interfaces.

Surface roughness

Tribology studies surface roughness effects on friction, wear, and lubrication performance, while lubrication engineering applies this knowledge to select and optimize lubricants that minimize surface roughness-related damage.

Boundary lubrication

Boundary lubrication in tribology studies friction and wear mechanisms under thin lubricant films, while lubrication engineering designs and optimizes lubricant formulations to minimize surface contact and reduce boundary wear.

Elastohydrodynamic lubrication

Elastohydrodynamic lubrication (EHL) in Tribology explores the formation of a highly pressurized lubricant film between elastic surfaces under high load, optimizing friction reduction and wear prevention beyond conventional lubrication engineering approaches.

Tribofilms

Tribofilms are critical in tribology by forming protective layers that reduce friction and wear, distinguishing tribology's broader study of friction, lubrication, and wear from lubrication engineering's specific focus on lubricant formulation and application.

Stribeck curve

The Stribeck curve in tribology illustrates the relationship between friction coefficient and lubrication regimes, highlighting critical transitions that lubrication engineering aims to optimize for reducing wear and enhancing machine efficiency.

Anti-scuff additives

Anti-scuff additives in tribology significantly enhance lubrication engineering by reducing metal surface wear and friction under extreme pressure conditions.

Contact mechanics

Tribology studies the principles of contact mechanics and friction, wear, and lubrication processes, while lubrication engineering applies these principles specifically to design and optimize lubricants and lubrication systems for minimizing friction and wear in mechanical contacts.

Viscosity index

Tribology studies friction, wear, and lubrication principles, while lubrication engineering applies these concepts to optimize lubricant viscosity index for enhanced machinery performance under varying temperatures.

Tribology vs Lubrication engineering Infographic

njnir.com

njnir.com