Casting allows the production of complex shapes and large components by pouring molten metal into molds, offering design flexibility and cost-effective manufacturing for intricate geometries. Forging, on the other hand, enhances mechanical properties by shaping metal through compressive forces, resulting in superior strength, grain refinement, and fatigue resistance. Choosing between casting and forging depends on the desired combination of mechanical performance, dimensional accuracy, and production volume.

Table of Comparison

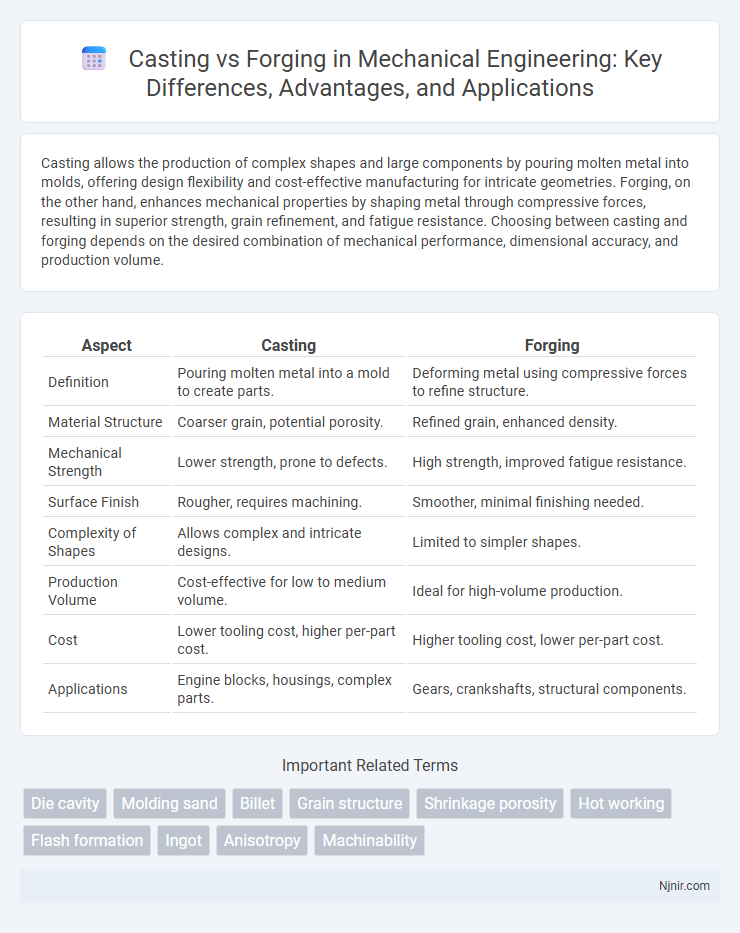

| Aspect | Casting | Forging |

|---|---|---|

| Definition | Pouring molten metal into a mold to create parts. | Deforming metal using compressive forces to refine structure. |

| Material Structure | Coarser grain, potential porosity. | Refined grain, enhanced density. |

| Mechanical Strength | Lower strength, prone to defects. | High strength, improved fatigue resistance. |

| Surface Finish | Rougher, requires machining. | Smoother, minimal finishing needed. |

| Complexity of Shapes | Allows complex and intricate designs. | Limited to simpler shapes. |

| Production Volume | Cost-effective for low to medium volume. | Ideal for high-volume production. |

| Cost | Lower tooling cost, higher per-part cost. | Higher tooling cost, lower per-part cost. |

| Applications | Engine blocks, housings, complex parts. | Gears, crankshafts, structural components. |

Introduction to Casting and Forging

Casting involves pouring molten metal into a mold to achieve the desired shape, making it ideal for complex geometries and large production runs. Forging shapes metal through compressive forces, enhancing mechanical properties such as strength and grain structure by aligning the metal's internal fibers. Both processes are fundamental in manufacturing, with casting offering design flexibility and forging providing superior structural integrity.

Fundamental Principles of Casting

Casting involves pouring molten metal into a mold where it solidifies, relying on principles such as fluidity, solidification, and mold design to achieve the desired shape and properties. Key factors include controlling cooling rates to minimize defects like porosity and shrinkage while ensuring uniform grain structure. Understanding thermal conductivity, mold material, and gating system layout is essential to optimize the structural integrity and surface finish of the final cast product.

Core Techniques in Forging Processes

Forging processes primarily involve shaping metal through localized compressive forces, typically using hammers or presses, which enhance the material's grain structure and mechanical properties. Core techniques include open-die forging, where the workpiece is deformed between flat dies allowing for versatile shapes, and closed-die forging, which uses specifically shaped dies to produce precise, complex components with superior strength. Impression-die forging and seamless rolled ring forging are critical methods that optimize dimensional accuracy and structural integrity in high-stress applications.

Comparison of Material Properties

Casting typically produces materials with a coarser microstructure, resulting in lower tensile strength and impact resistance compared to forging. Forged components exhibit refined grain flow and reduced porosity, enhancing mechanical properties such as fatigue strength and durability. The material density and internal integrity achieved through forging make it ideal for high-stress applications where superior strength and toughness are critical.

Typical Applications in Industry

Casting is widely used in the automotive and aerospace industries for producing complex shapes like engine blocks and turbine housings, where intricate detailing and dimensional accuracy are critical. Forging is preferred in heavy machinery, construction, and automotive sectors for components such as crankshafts, gears, and connecting rods due to its superior strength and durability. High-stress applications in the oil and gas industry also rely on forged parts to withstand extreme pressure and harsh environments.

Advantages of Casting Methods

Casting methods offer significant advantages such as the ability to produce complex shapes with intricate details and internal cavities that are difficult or impossible to achieve with forging. The process supports high-volume production with minimal material waste due to precise mold designs, enhancing cost efficiency. Casting also allows for the use of a wide range of metals and alloys, providing versatility in mechanical properties and applications.

Benefits of Forging Techniques

Forging techniques produce components with superior mechanical properties such as increased strength, toughness, and fatigue resistance due to the refined grain structure achieved through plastic deformation. Forged parts exhibit enhanced reliability and durability, making them ideal for critical applications in aerospace, automotive, and industrial machinery. These processes also reduce porosity and internal defects compared to casting, ensuring higher structural integrity.

Limitations and Challenges of Each Process

Casting faces limitations such as porosity, shrinkage defects, and slower cooling rates that can lead to coarse microstructures and reduced mechanical properties. Forging challenges include high equipment costs, limited part complexity, and the risk of material waste due to excessive flash removal. Both processes require careful control of parameters to minimize defects and ensure consistent quality in manufacturing.

Cost and Efficiency Considerations

Casting typically offers lower initial tooling costs and is suitable for producing complex shapes with minimal machining, making it cost-effective for small to medium production runs. Forging involves higher upfront expenses due to specialized dies and equipment but provides superior material strength and less waste, resulting in greater efficiency for high-volume manufacturing. The choice between casting and forging depends on balancing per-unit costs with production scale, mechanical requirements, and lead time constraints.

Selection Criteria: Casting vs Forging

Selection criteria for casting versus forging primarily depend on factors such as material properties, mechanical strength, and production volume. Forging is favored for components requiring superior tensile strength, fatigue resistance, and toughness due to its grain refinement and directional grain flow. Casting suits complex geometries, intricate designs, and lower production costs, especially for large, non-load bearing parts or prototypes with tight dimensional tolerances.

Die cavity

Die cavities in forging are typically designed for precise metal flow and grain structure control, while casting die cavities prioritize complex shape formation and surface finish.

Molding sand

Molding sand used in casting offers flexibility for complex shapes but has lower strength compared to the high-pressure resistance of forging molds.

Billet

Billet forging enhances mechanical properties and structural integrity compared to casting by refining grain structure and reducing defects in metal billets.

Grain structure

Forging produces a refined, aligned grain structure enhancing mechanical strength and toughness, whereas casting typically results in a coarse, dendritic grain structure with potential porosity and reduced material properties.

Shrinkage porosity

Shrinkage porosity is more prevalent in casting due to uneven cooling and solidification, whereas forging significantly reduces this defect by applying pressure that consolidates metal and eliminates internal voids.

Hot working

Hot working processes like forging refine metal grain structure and enhance mechanical properties more effectively than casting, which involves pouring molten metal into molds.

Flash formation

Flash formation during forging occurs as excess metal is expelled from the die cavity under high pressure, unlike casting where no flash typically forms due to metal solidifying in the mold.

Ingot

Ingot casting involves pouring molten metal into molds to form solid blocks, while ingot forging reshapes these solidified blocks under high pressure to enhance metal grain structure and mechanical properties.

Anisotropy

Forging produces parts with superior anisotropy due to grain alignment under directional compressive forces, while casting typically results in isotropic or less directionally dependent properties due to random solidification patterns.

Machinability

Forged metals generally exhibit superior machinability compared to cast metals due to their refined grain structure and reduced porosity.

casting vs forging Infographic

njnir.com

njnir.com