Soft robotics utilize flexible materials that allow for adaptive, gentle interactions with environments, contrasting with the rigid structures of traditional robotics that offer precision and strength. This flexibility enables soft robots to perform tasks in unstructured or delicate settings where traditional robots might cause damage or fail. Innovations in soft robotics focus on bio-inspired designs and compliant actuators to enhance versatility and safety in applications like medical devices and wearable technology.

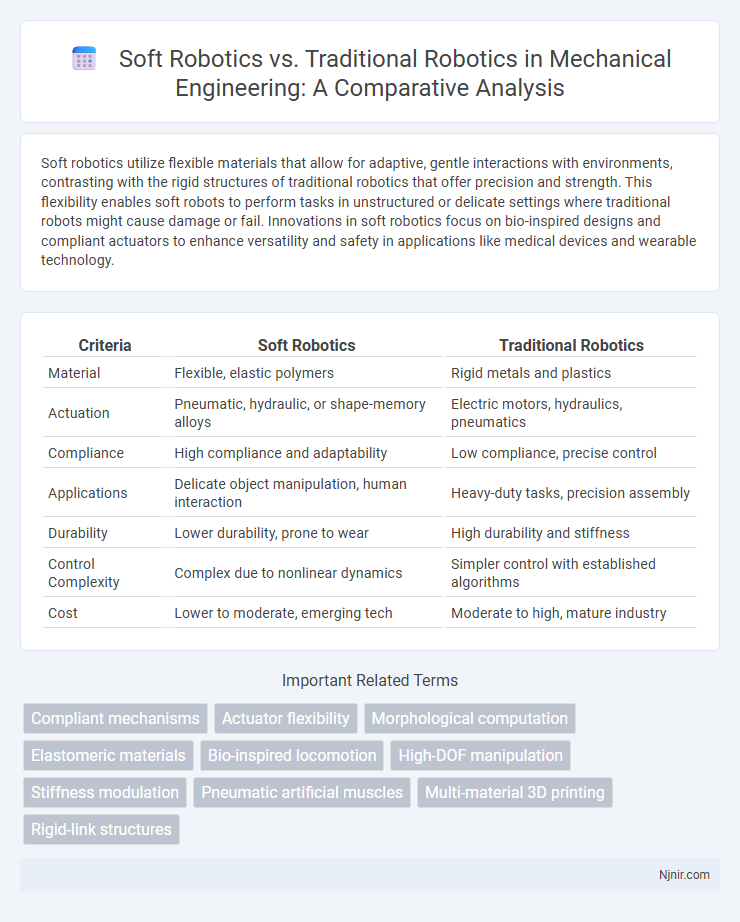

Table of Comparison

| Criteria | Soft Robotics | Traditional Robotics |

|---|---|---|

| Material | Flexible, elastic polymers | Rigid metals and plastics |

| Actuation | Pneumatic, hydraulic, or shape-memory alloys | Electric motors, hydraulics, pneumatics |

| Compliance | High compliance and adaptability | Low compliance, precise control |

| Applications | Delicate object manipulation, human interaction | Heavy-duty tasks, precision assembly |

| Durability | Lower durability, prone to wear | High durability and stiffness |

| Control Complexity | Complex due to nonlinear dynamics | Simpler control with established algorithms |

| Cost | Lower to moderate, emerging tech | Moderate to high, mature industry |

Introduction to Soft Robotics and Traditional Robotics

Soft robotics utilizes flexible materials and bio-inspired designs to mimic natural movements, enabling safer interaction with humans and delicate objects. Traditional robotics relies on rigid components and precise control systems for tasks demanding high accuracy and strength in structured environments. The emergence of soft robotics complements conventional methods by addressing limitations in adaptability and compliance inherent in traditional robotic systems.

Key Differences in Design Principles

Soft robotics employ flexible, compliant materials such as silicone and elastomers, enabling adaptation to complex, delicate environments, unlike traditional robotics that rely on rigid components like metal and hard plastics for precise, high-load tasks. The design principles of soft robotics emphasize bio-inspiration, continuous deformation, and intrinsic safety, contrasting with the rigid kinematics and discrete joint articulations typical in traditional robotic systems. Control strategies in soft robotics leverage sensor integration and fluidic actuation to manage elasticity and variability, while conventional robots use motors and rigid linkages for predictable, repeatable motion.

Materials Used in Soft vs Traditional Robots

Soft robotics primarily utilize flexible materials such as silicones, elastomers, and hydrogels, which allow for adaptable, lifelike movements and safe interaction with humans. Traditional robotics rely on rigid metals, plastics, and ceramics to provide structural strength, precision, and durability in industrial and manufacturing applications. The choice of materials directly influences the robots' design, functionality, and scope of use, with soft materials enabling compliance and traditional materials ensuring stability and load-bearing capacity.

Control Systems and Actuation Methods

Soft robotics utilize flexible materials and compliant structures that require advanced, adaptive control systems for precise manipulation, contrasting with traditional robotics which rely on rigid components and well-defined control algorithms. Actuation in soft robots often employs pneumatic, hydraulic, or shape-memory alloys enabling smooth, organic movements, whereas traditional robots primarily use electric motors or hydraulic actuators for linear and rotary motions. The control systems in soft robotics must accommodate nonlinear behaviors and continuous deformation, leading to the integration of sensor feedback and machine learning techniques for enhanced responsiveness and adaptability.

Performance in Complex Environments

Soft robotics exhibits superior adaptability and flexibility in complex environments compared to traditional rigid robots, enabling safer interaction with unpredictable surroundings. Its compliant materials and dexterous movements allow for delicate object manipulation and navigation through unstructured terrains, reducing damage risks. Traditional robotics often struggles with rigidity and limited degrees of freedom, which can hinder performance in dynamic and sensitive tasks.

Applications Across Industries

Soft robotics offers enhanced adaptability and safety for delicate tasks, making it ideal for medical devices, agricultural harvesting, and food processing industries. Traditional robotics excels in precision and strength, suitable for automotive manufacturing, heavy machinery assembly, and electronics production. The integration of soft and traditional robotics drives innovation, optimizing efficiency and functionality across diverse industrial applications.

Advantages of Soft Robotics Over Conventional Robotics

Soft robotics offers superior adaptability and flexibility compared to traditional rigid robots, enabling safer interaction with humans and delicate objects. Their compliant materials and structures allow for enhanced dexterity in unstructured environments, which conventional robotics often struggle to navigate. Soft robots also excel in energy efficiency and can better absorb shocks and impacts, reducing mechanical wear and increasing operational longevity.

Challenges and Limitations of Soft and Traditional Robots

Soft robotics face challenges such as limited load-bearing capacity, slower response times, and difficulties in precise control due to their flexible materials and complex deformation patterns. Traditional robots encounter limitations including rigid structures that restrict adaptability and safety concerns when operating alongside humans, as well as higher costs and maintenance requirements due to complex mechanical parts. Both types struggle with scalability and integration in dynamic environments, highlighting ongoing research efforts to enhance materials and control algorithms for improved performance.

Recent Innovations and Research Trends

Recent innovations in soft robotics emphasize flexible, bio-inspired materials and actuators that mimic natural muscle movements, enabling safer human-robot interaction and enhanced adaptability in unstructured environments. Research trends highlight advancements in soft sensors, stretchable electronics, and 3D printing technologies that facilitate the development of lightweight, compliant robotic systems with improved dexterity and resilience. Traditional robotics continues to evolve with enhanced AI algorithms and precision control but often lacks the inherent flexibility and compliance found in emerging soft robotic designs.

Future Prospects and Integration Opportunities

Soft robotics offers enhanced adaptability and safer human-robot interaction, positioning it as a transformative technology in fields like healthcare and wearable devices. Traditional robotics excels in precision and strength, which remains crucial for manufacturing and industrial automation. Integrating soft and traditional robotics can create hybrid systems that leverage flexibility and power, driving innovation in sectors such as agriculture, prosthetics, and collaborative robotics.

Compliant mechanisms

Soft robotics utilize compliant mechanisms made from flexible materials to achieve adaptive, safe interactions, unlike traditional robotics which rely on rigid structures for precise but less adaptable motion.

Actuator flexibility

Soft robotics utilize highly flexible actuators made from compliant materials enabling adaptable, safe interactions, while traditional robotics rely on rigid actuators that limit flexibility and adaptability in dynamic environments.

Morphological computation

Soft robotics leverages morphological computation by utilizing flexible, deformable materials that enable adaptive, efficient interactions with complex environments, unlike traditional robotics which rely on rigid structures and explicit control algorithms.

Elastomeric materials

Elastomeric materials in soft robotics enable flexible, adaptive movements and safer human interaction, contrasting with rigid components used in traditional robotics that prioritize precision and strength.

Bio-inspired locomotion

Soft robotics utilize bio-inspired locomotion by mimicking natural muscle movements and flexible structures, enabling enhanced adaptability and safer interaction compared to the rigid, joint-based mechanisms of traditional robotics.

High-DOF manipulation

Soft robotics offers superior High-DOF manipulation compared to traditional robotics by enabling flexible, adaptive movements that mimic natural dexterity in complex, unstructured environments.

Stiffness modulation

Soft robotics achieves superior stiffness modulation through flexible materials and adaptive structures, enabling safer human interaction and versatile task execution compared to the fixed rigidity of traditional robotics.

Pneumatic artificial muscles

Pneumatic artificial muscles in soft robotics provide enhanced flexibility, lightweight design, and safer human-robot interaction compared to the rigid structure and limited adaptability of traditional robotics.

Multi-material 3D printing

Multi-material 3D printing enhances soft robotics by enabling the fabrication of flexible, multi-functional components that traditional robotics with rigid materials cannot achieve.

Rigid-link structures

Soft robotics utilizes flexible, deformable materials for adaptable manipulation, whereas traditional robotics relies on rigid-link structures offering precision and strength in industrial applications.

Soft robotics vs traditional robotics Infographic

njnir.com

njnir.com