Hydrodynamic bearings rely on a fluid film generated by relative motion between the bearing surface and the shaft, creating a pressure that supports the load without direct contact. Hydrostatic bearings, in contrast, use an external pump to supply pressurized lubricant, maintaining a stable fluid film even at low speeds or start-up conditions. Hydrodynamic bearings are preferred for applications with continuous motion, while hydrostatic bearings excel in precision machinery requiring low friction and vibration under variable load conditions.

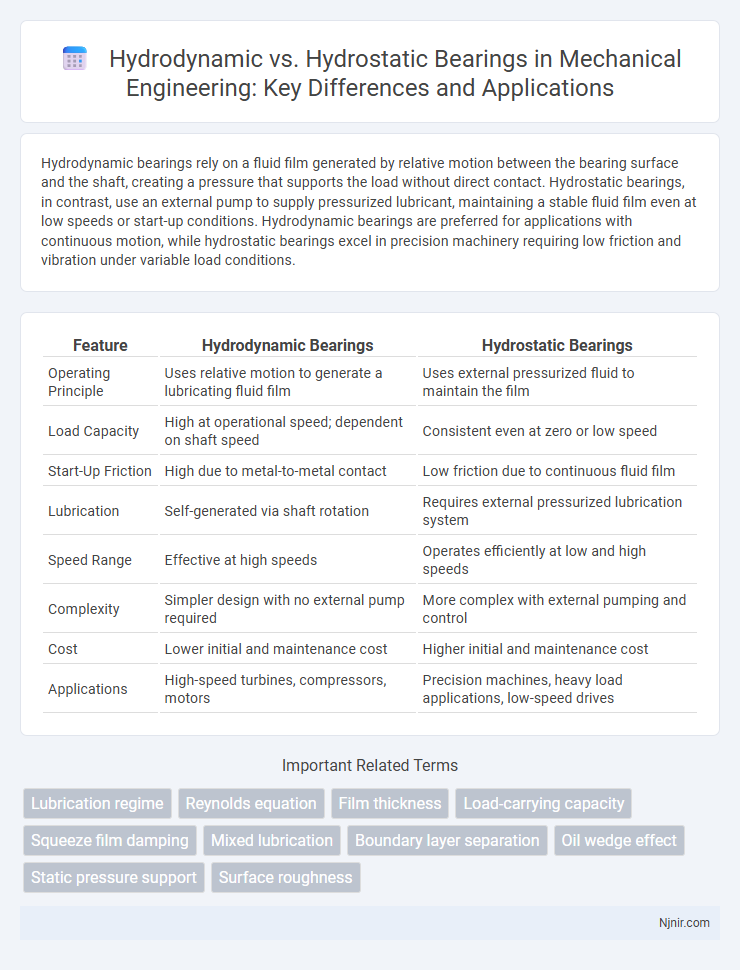

Table of Comparison

| Feature | Hydrodynamic Bearings | Hydrostatic Bearings |

|---|---|---|

| Operating Principle | Uses relative motion to generate a lubricating fluid film | Uses external pressurized fluid to maintain the film |

| Load Capacity | High at operational speed; dependent on shaft speed | Consistent even at zero or low speed |

| Start-Up Friction | High due to metal-to-metal contact | Low friction due to continuous fluid film |

| Lubrication | Self-generated via shaft rotation | Requires external pressurized lubrication system |

| Speed Range | Effective at high speeds | Operates efficiently at low and high speeds |

| Complexity | Simpler design with no external pump required | More complex with external pumping and control |

| Cost | Lower initial and maintenance cost | Higher initial and maintenance cost |

| Applications | High-speed turbines, compressors, motors | Precision machines, heavy load applications, low-speed drives |

Introduction to Hydrodynamic and Hydrostatic Bearings

Hydrodynamic bearings support loads through a continuous fluid film generated by relative motion between the bearing surfaces, creating a pressure that separates the surfaces and reduces friction. Hydrostatic bearings, in contrast, maintain a fluid film by externally pressurizing the lubricant, providing load support even at zero relative motion. Both bearing types are critical in high-precision machinery where minimizing wear and vibration is essential for performance and longevity.

Principles of Operation: Hydrodynamic vs Hydrostatic Bearings

Hydrodynamic bearings operate by creating a load-carrying fluid film through relative motion between the bearing surface and the shaft, generating pressure that supports the load without direct contact. Hydrostatic bearings maintain a fluid film by externally pressurizing the lubricant, allowing load support even at zero or low shaft speed. These operational differences influence performance characteristics such as friction, wear, and the ability to support heavy loads under varying operational conditions.

Key Differences in Design and Functionality

Hydrodynamic bearings rely on a continuous fluid film generated by relative motion between the bearing and the shaft, creating a pressure distribution that supports the load without physical contact. Hydrostatic bearings maintain a fluid film through an external pressurized fluid supply, providing load support even at zero or low shaft speed. Design-wise, hydrodynamic bearings typically feature simpler structures but require high shaft speeds to develop the fluid film, whereas hydrostatic bearings incorporate complex fluid supply systems enabling stable operation under varying loads and speeds.

Load-Carrying Capabilities of Both Bearing Types

Hydrodynamic bearings generate a fluid film through relative motion between the bearing and the shaft, allowing them to support high loads while minimizing direct contact and wear. Hydrostatic bearings rely on an external pump to supply pressurized fluid, providing consistent load support even at zero or low speeds, which enhances load-carrying capabilities under varying operational conditions. The load capacity of hydrostatic bearings is generally higher at startup or low speeds, whereas hydrodynamic bearings excel under steady-state, high-speed conditions due to the dynamic formation of the fluid film.

Lubrication Methods: Hydrodynamic vs Hydrostatic Systems

Hydrodynamic bearings rely on a thin film of lubricant generated by relative motion between the bearing surfaces, creating a pressure that supports the load without direct contact. Hydrostatic bearings use an externally pressurized lubricant supplied through pumps, maintaining a stable film regardless of motion, enabling load support at low or zero speeds. Both methods ensure reduced friction and wear, but hydrostatic systems offer superior stiffness and damping due to controlled lubricant pressure.

Applications and Suitable Use-Cases

Hydrodynamic bearings find extensive applications in high-speed turbines, compressors, and electric motors where continuous relative motion generates a lubricant film for frictionless operation. Hydrostatic bearings suit precision machine tools, semiconductor manufacturing equipment, and heavy-load applications requiring stability and minimal wear under low or zero relative motion due to externally pressurized lubricant supply. Both bearing types optimize performance based on load, speed, and lubrication conditions, with hydrodynamic bearings excelling in dynamic high-speed environments and hydrostatic bearings providing superior support in low-speed, high-precision settings.

Efficiency and Performance Comparison

Hydrodynamic bearings achieve high efficiency through a full fluid film that supports the load, reducing friction and wear during operation, which is ideal for high-speed applications. Hydrostatic bearings maintain performance by using an external pressurized fluid supply to provide a constant film thickness, ensuring minimal friction even at low speeds or during start-up conditions. The efficiency of hydrodynamic bearings increases with speed, while hydrostatic bearings offer consistent performance regardless of operational speed, making them suitable for precision machinery requiring stable load support.

Maintenance and Operational Considerations

Hydrodynamic bearings require continuous lubrication and precise shaft alignment to maintain the oil film that prevents metal-to-metal contact, making routine monitoring of oil quality and viscosity essential for optimal performance. Hydrostatic bearings rely on an external pressurized fluid supply, leading to simpler start-up procedures and reduced risk of wear during low-speed operation, but they demand meticulous maintenance of pumps and control systems to avoid pressure drops or contamination. Both bearing types necessitate regular inspection, yet hydrodynamic systems often exhibit longer service intervals due to self-generated films, whereas hydrostatic systems provide better load support stability under varying operational conditions.

Advantages and Limitations of Each Bearing Type

Hydrodynamic bearings offer the advantage of generating a full fluid film during operation, providing low friction and excellent load-carrying capacity without external pressurization, but they require relative motion to maintain the lubricant film, making them less effective during startup or low-speed conditions. Hydrostatic bearings maintain a fluid film through external pressurized lubrication regardless of shaft speed, delivering consistent support at zero or low speeds and reducing wear, though they involve higher complexity, energy consumption, and maintenance due to pumping systems. Both bearing types are critical in applications requiring vibration damping and high precision, with hydrodynamic bearings favored for high-speed machinery and hydrostatic bearings preferred in precision tools and sensitive equipment.

Future Trends in Bearing Technology

Future trends in bearing technology emphasize the integration of smart materials and real-time condition monitoring in both hydrodynamic and hydrostatic bearings to enhance performance and reliability. Advances in additive manufacturing enable complex bearing geometries, improving lubrication efficiency and load capacity, particularly for hydrodynamic designs. Increasing adoption of hybrid bearing systems combining hydrostatic load support with hydrodynamic film formation aims to reduce energy consumption and extend operational life in industrial applications.

Lubrication regime

Hydrodynamic bearings operate under a full fluid film lubrication regime creating a pressure-induced supporting film, while hydrostatic bearings rely on externally pressurized lubricant to maintain a fluid film regardless of relative motion.

Reynolds equation

Reynolds equation, a fundamental differential equation in fluid dynamics, models the pressure distribution in hydrodynamic bearings where fluid film lubrication supports load dynamically, unlike hydrostatic bearings that rely on externally pressurized fluid, eliminating relative motion-induced pressure variations.

Film thickness

Hydrodynamic bearings maintain a thicker fluid film through relative motion generating pressure, while hydrostatic bearings rely on external pressurized fluid to sustain a thinner, more stable film thickness independent of shaft speed.

Load-carrying capacity

Hydrodynamic bearings provide higher load-carrying capacity due to fluid film formation under relative motion, whereas hydrostatic bearings rely on external pressurized fluid supply, offering consistent load support even at zero speed.

Squeeze film damping

Hydrodynamic bearings generate a continuous lubricant film via relative motion reducing friction, while hydrostatic bearings maintain a pressurized lubricant film independent of motion, offering superior squeeze film damping for enhanced vibration control and stability.

Mixed lubrication

Mixed lubrication in hydrodynamic and hydrostatic bearings occurs when a thin fluid film partially separates surfaces, combining hydrodynamic fluid pressure generation with direct surface contact and elastohydrodynamic effects to optimize load capacity and reduce friction.

Boundary layer separation

Hydrodynamic bearings maintain a stable lubricant film preventing boundary layer separation, whereas hydrostatic bearings rely on external pressurized fluid that minimizes separation risk but can experience localized boundary layer disruptions under load variations.

Oil wedge effect

Hydrodynamic bearings generate a pressure oil wedge through relative motion creating fluid film lubrication, whereas hydrostatic bearings maintain a pressurized oil wedge via external pumping independent of motion.

Static pressure support

Hydrostatic bearings provide static pressure support through an external pressurized fluid supply, ensuring load carrying capacity at zero or low speeds, unlike hydrodynamic bearings that rely on relative motion to generate dynamic pressure.

Surface roughness

Hydrodynamic bearings require smoother surface roughness to maintain a stable lubricating film, while hydrostatic bearings can tolerate rougher surfaces due to external pressurized fluid support.

hydrodynamic vs hydrostatic bearings Infographic

njnir.com

njnir.com