Fused deposition modeling (FDM) uses thermoplastic filaments heated and extruded layer by layer, offering cost-effective prototyping with durable parts suitable for functional testing. Stereolithography (SLA) employs laser curing of photopolymer resins to achieve superior surface finish and high precision in complex geometries, ideal for detailed and smooth prototypes. Choosing between FDM and SLA depends on factors such as part strength, surface quality, production speed, and budget constraints in mechanical engineering applications.

Table of Comparison

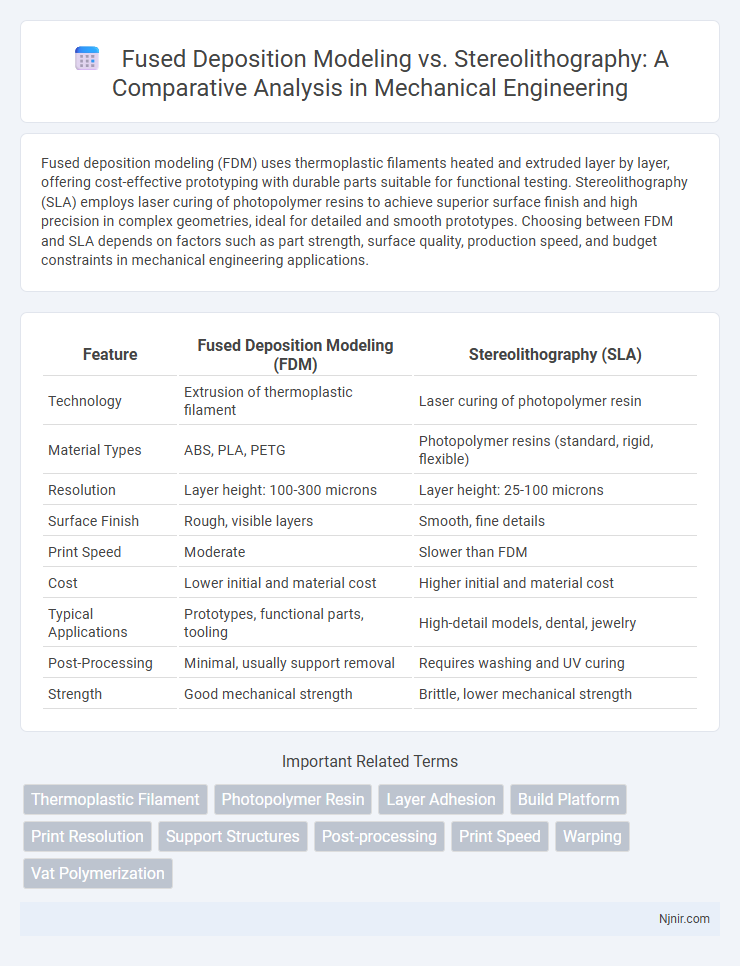

| Feature | Fused Deposition Modeling (FDM) | Stereolithography (SLA) |

|---|---|---|

| Technology | Extrusion of thermoplastic filament | Laser curing of photopolymer resin |

| Material Types | ABS, PLA, PETG | Photopolymer resins (standard, rigid, flexible) |

| Resolution | Layer height: 100-300 microns | Layer height: 25-100 microns |

| Surface Finish | Rough, visible layers | Smooth, fine details |

| Print Speed | Moderate | Slower than FDM |

| Cost | Lower initial and material cost | Higher initial and material cost |

| Typical Applications | Prototypes, functional parts, tooling | High-detail models, dental, jewelry |

| Post-Processing | Minimal, usually support removal | Requires washing and UV curing |

| Strength | Good mechanical strength | Brittle, lower mechanical strength |

Introduction to Additive Manufacturing Techniques

Fused Deposition Modeling (FDM) and Stereolithography (SLA) represent two prominent additive manufacturing techniques used to create three-dimensional objects layer by layer from digital models. FDM utilizes thermoplastic filaments melted and extruded through a nozzle, offering cost-effective prototyping with durable parts, while SLA employs a UV laser to cure liquid resin, delivering high-resolution and finely detailed components. Both techniques offer unique advantages in terms of materials, precision, and application scope, making them essential in rapid prototyping and customized manufacturing sectors.

Overview of Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is an additive manufacturing process that builds parts layer-by-layer by extruding thermoplastic filaments through a heated nozzle, offering affordability and ease of use for prototyping and small-scale production. FDM supports a wide range of materials, including ABS, PLA, and flexible filaments, enabling versatile applications across industries such as automotive, aerospace, and consumer goods. Compared to Stereolithography (SLA), FDM generally provides faster build times and robust mechanical properties, though with lower resolution and surface finish quality.

Overview of Stereolithography (SLA)

Stereolithography (SLA) is an additive manufacturing process that uses a UV laser to cure liquid photopolymer resin layer by layer, creating highly detailed and smooth 3D models. SLA offers superior surface finish and precision compared to Fused Deposition Modeling (FDM), making it ideal for applications requiring intricate geometries and fine features. This technology excels in producing prototypes, dental models, and jewelry, where accuracy and detail are critical.

Materials Used in FDM vs SLA

Fused Deposition Modeling (FDM) primarily uses thermoplastic filaments such as PLA, ABS, and PETG, offering durability and flexibility suitable for functional prototypes and mechanical parts. Stereolithography (SLA) utilizes liquid photopolymer resins cured by a UV laser, providing superior surface finish and high detail for intricate designs and fine features. Material properties in SLA resins vary widely, including clear, flexible, and castable types, whereas FDM materials focus on strength, impact resistance, and temperature tolerance.

Printing Resolution and Surface Finish Comparison

Fused Deposition Modeling (FDM) typically offers lower printing resolution, with layer heights ranging from 100 to 300 microns, resulting in visible layer lines and a rougher surface finish. In contrast, Stereolithography (SLA) excels in high-resolution printing, achieving layer heights as fine as 25 microns, producing smoother surfaces with intricate details and minimal post-processing requirements. The superior surface finish of SLA makes it ideal for applications demanding precision and fine aesthetics, while FDM is suited for functional prototypes with less emphasis on surface quality.

Mechanical Properties of FDM vs SLA Parts

Fused Deposition Modeling (FDM) parts typically exhibit lower tensile strength and surface finish compared to Stereolithography (SLA) parts, which offer superior mechanical accuracy and smoother surface quality due to their photopolymer resin bases. SLA parts generally possess higher resolution and better isotropic mechanical properties, making them ideal for applications requiring fine detail and stronger material integrity. In contrast, FDM parts may suffer from anisotropic strength and layer adhesion issues, limiting their performance under mechanical stress relative to SLA components.

Speed and Efficiency of Printing Processes

Fused Deposition Modeling (FDM) generally offers faster print times due to its straightforward layer-by-layer extrusion of thermoplastic filaments, making it efficient for rapid prototyping and functional parts. Stereolithography (SLA), while slower because of its laser curing process, provides higher precision and smoother surface finishes, ideal for detailed and complex models. The efficiency trade-off depends on application needs: FDM excels in quick, cost-effective production, whereas SLA prioritizes print accuracy and fine detail over speed.

Cost Analysis: FDM vs SLA

Fused Deposition Modeling (FDM) typically offers lower initial equipment costs and more affordable consumables, making it a budget-friendly option for prototyping and small-scale production. In contrast, Stereolithography (SLA) incurs higher expenses due to advanced resin materials and maintenance requirements, but delivers superior detail and surface finish suitable for precision applications. Operational costs for FDM remain lower over time, whereas SLA's costs can escalate with resin waste and post-processing labor.

Typical Applications in Mechanical Engineering

Fused Deposition Modeling (FDM) is widely used in mechanical engineering for creating functional prototypes, jigs, and fixtures due to its cost-effectiveness and ability to produce durable thermoplastic parts like ABS and PLA. Stereolithography (SLA) excels in applications requiring high-resolution, intricate geometries and smooth surface finishes, making it ideal for detailed functional prototypes, mold masters, and precision components. FDM suits engineering applications involving robust mechanical testing, while SLA is preferred for parts requiring fine detail and tight tolerances in mechanical design validation.

Choosing Between FDM and SLA for Engineering Projects

Fused deposition modeling (FDM) offers cost-effective prototyping with durable thermoplastic materials ideal for functional engineering parts, while stereolithography (SLA) provides superior surface finish and intricate detail suited for precision models and complex geometries. Engineers prioritize FDM for strength and rapid iteration in mechanical components, whereas SLA excels in applications demanding high resolution and smooth aesthetics, such as molds or detailed assemblies. Material compatibility, desired part accuracy, and project budget are critical factors guiding the selection between FDM and SLA technologies for engineering applications.

Thermoplastic Filament

Fused deposition modeling (FDM) uses thermoplastic filament melted and extruded layer-by-layer to build durable parts, whereas stereolithography (SLA) relies on photopolymer resin cured by UV light, making FDM preferred for strong, heat-resistant thermoplastic prototypes.

Photopolymer Resin

Fused deposition modeling (FDM) uses thermoplastic filaments, while stereolithography (SLA) employs photopolymer resin cured by UV light for higher resolution and smoother surface finishes.

Layer Adhesion

Fused deposition modeling achieves strong layer adhesion through thermal bonding of extruded thermoplastic, while stereolithography relies on photopolymerization with UV light to chemically bond resin layers.

Build Platform

Fused Deposition Modeling (FDM) features a heated, typically removable build platform for layer adhesion and warping prevention, while Stereolithography (SLA) uses a stationary, highly precise platform submerged in resin for superior surface finish and detail accuracy.

Print Resolution

Fused deposition modeling typically offers lower print resolution around 100-300 microns, while stereolithography achieves higher precision with resolutions as fine as 25-100 microns.

Support Structures

Fused deposition modeling (FDM) requires more extensive and removable support structures due to its layer-by-layer extrusion of thermoplastics, whereas stereolithography (SLA) uses photo-curable resin that enables finer, less bulky supports with easier post-processing removal.

Post-processing

Fused deposition modeling (FDM) requires minimal post-processing such as support removal and surface sanding, while stereolithography (SLA) demands extensive post-curing and resin washing to achieve high-resolution surface finish.

Print Speed

Fused deposition modeling offers faster print speeds compared to stereolithography due to its layer-by-layer extrusion process versus the slower resin curing in stereolithography.

Warping

Fused deposition modeling (FDM) commonly experiences warping due to uneven cooling and shrinkage of thermoplastic layers, whereas stereolithography (SLA) exhibits minimal warping because it cures liquid resin with precise ultraviolet light, ensuring greater dimensional accuracy.

Vat Polymerization

Vat Polymerization in Stereolithography offers higher resolution and smoother surface finishes compared to the layer-by-layer extrusion process of Fused Deposition Modeling.

Fused deposition modeling vs Stereolithography Infographic

njnir.com

njnir.com