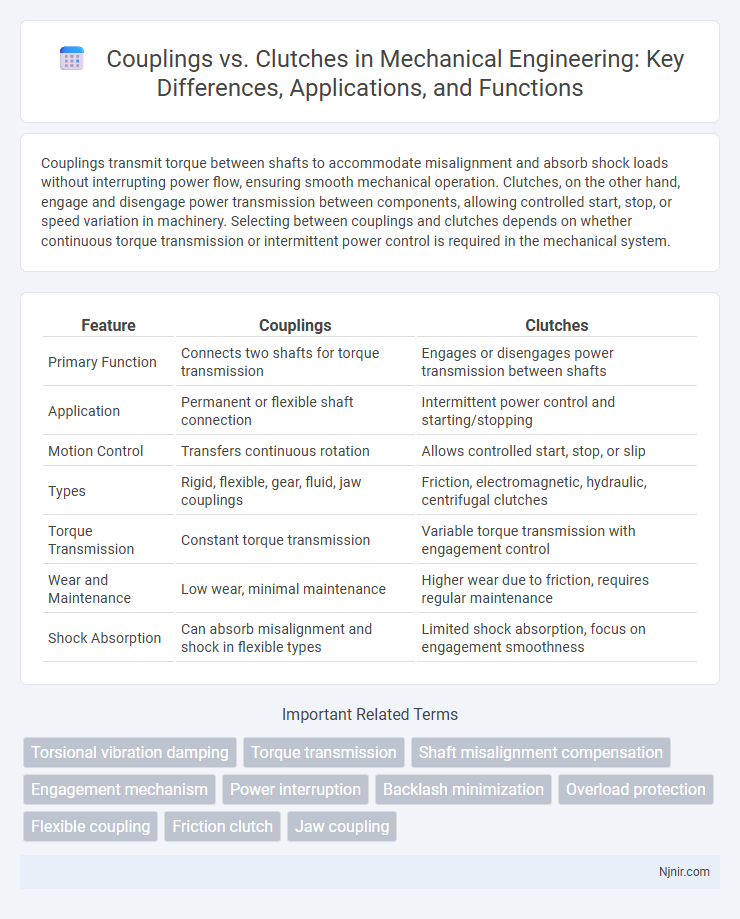

Couplings transmit torque between shafts to accommodate misalignment and absorb shock loads without interrupting power flow, ensuring smooth mechanical operation. Clutches, on the other hand, engage and disengage power transmission between components, allowing controlled start, stop, or speed variation in machinery. Selecting between couplings and clutches depends on whether continuous torque transmission or intermittent power control is required in the mechanical system.

Table of Comparison

| Feature | Couplings | Clutches |

|---|---|---|

| Primary Function | Connects two shafts for torque transmission | Engages or disengages power transmission between shafts |

| Application | Permanent or flexible shaft connection | Intermittent power control and starting/stopping |

| Motion Control | Transfers continuous rotation | Allows controlled start, stop, or slip |

| Types | Rigid, flexible, gear, fluid, jaw couplings | Friction, electromagnetic, hydraulic, centrifugal clutches |

| Torque Transmission | Constant torque transmission | Variable torque transmission with engagement control |

| Wear and Maintenance | Low wear, minimal maintenance | Higher wear due to friction, requires regular maintenance |

| Shock Absorption | Can absorb misalignment and shock in flexible types | Limited shock absorption, focus on engagement smoothness |

Introduction to Couplings and Clutches

Couplings and clutches are essential mechanical components that transmit power between shafts in machinery. Couplings are primarily designed to connect two rotating shafts to transfer torque while accommodating misalignment and reducing vibration. Clutches, in contrast, enable the engagement and disengagement of power transmission, allowing controlled starting, stopping, or speed variation in machines.

Fundamental Differences Between Couplings and Clutches

Couplings transmit torque between two shafts while accommodating misalignment and reducing vibration, whereas clutches control power transmission by engaging or disengaging the drive between shafts. Couplings operate continuously to connect rotating equipment, whereas clutches enable intermittent motion transfer and load control. The fundamental difference lies in couplings providing a flexible mechanical link, while clutches serve as a selective coupling for controlled start, stop, or slip functions.

Working Principles: Couplings vs Clutches

Couplings transmit torque between two shafts by maintaining a continuous connection, enabling power transfer and accommodating misalignment or axial movement without interrupting motion. Clutches engage or disengage power transmission by controlling frictional contact between two rotating components, allowing intermittent or controlled torque transfer. The working principle of couplings ensures constant mechanical linkage, while clutches provide selective engagement to start, stop, or regulate power flow in machinery.

Types of Couplings in Mechanical Systems

Types of couplings in mechanical systems include rigid couplings, flexible couplings, and fluid couplings, each serving to connect shafts for power transmission while accommodating misalignment and vibrations. Rigid couplings, such as sleeve or flange couplings, provide solid shaft connections with no allowance for misalignment, ideal for precise alignment applications. Flexible couplings, like jaw, disc, or gear couplings, compensate for angular, parallel, and axial misalignments, enhancing system durability and reducing shock loads.

Types of Clutches in Mechanical Systems

Mechanical systems utilize various types of clutches, including friction clutches, which rely on frictional force between surfaces to transmit torque; centrifugal clutches, which engage automatically based on rotational speed; and electromagnetic clutches, activated by an electric current to enable quick and precise control. Positive clutches, such as dog clutches and jaw clutches, provide direct mechanical engagement by interlocking components, ensuring no slip during torque transmission. Each clutch type serves specific applications, balancing factors like torque capacity, engagement smoothness, and control responsiveness in mechanical drive systems.

Applications: Where Couplings Are Preferred

Couplings are preferred in applications requiring the transmission of torque between shafts while accommodating misalignment, such as in conveyor systems, pumps, and compressors. They efficiently absorb shock loads and vibrations in heavy machinery, ensuring smoother operation and reducing wear. Industrial automation and manufacturing equipment often utilize couplings for their ability to maintain alignment and protect connected components from damage.

Applications: Where Clutches Are Essential

Clutches are essential in automotive drivetrains for engaging and disengaging power transmission between the engine and wheels, allowing smooth gear changes and vehicle control. Industrial machinery relies on clutches to protect equipment by managing torque transfer and preventing overload during startup or operation. In robotics and automation, clutches enable precise control of movement by selectively transmitting power to specific components, enhancing performance and safety.

Performance Comparison: Torque, Speed, and Alignment

Couplings offer superior torque transmission capabilities and better accommodate misalignment, making them ideal for high-speed applications requiring flexibility. Clutches excel in controlling speed and load engagement by allowing torque transfer to be started, stopped, or modulated, which is essential for variable-speed machinery. While couplings prioritize continuous torque and alignment tolerance, clutches are optimized for dynamic speed control and load management.

Selection Criteria for Couplings and Clutches

Selection criteria for couplings emphasize torque capacity, misalignment compensation, and vibration dampening to ensure reliable power transmission and longevity in mechanical systems. Clutch selection prioritizes engagement torque, speed range, and thermal dissipation to achieve precise control over power transfer and prevent slippage. Both components require careful consideration of operating conditions, maintenance requirements, and compatibility with the driving and driven equipment for optimal performance.

Maintenance and Reliability Considerations

Couplings generally require less maintenance than clutches due to their simpler design and fewer moving parts, enhancing overall system reliability. Clutches experience higher wear because of frequent engagement and disengagement, necessitating regular inspection and potential replacement of friction components. Choosing the appropriate device depends on balancing operational demands with maintenance capabilities to ensure optimal equipment longevity and performance.

Torsional vibration damping

Couplings provide flexible connection with moderate torsional vibration damping, while clutches offer controlled engagement and superior torsional vibration absorption for precise torque transfer.

Torque transmission

Couplings provide flexible torque transmission between rotating shafts to accommodate misalignment and reduce vibration, while clutches enable controlled torque transfer by engaging or disengaging power flow in mechanical systems.

Shaft misalignment compensation

Couplings compensate for shaft misalignment by flexing or deforming to absorb angular, parallel, and axial misalignments, whereas clutches primarily transmit torque without significant misalignment accommodation.

Engagement mechanism

Couplings transmit torque through flexible or rigid connections adapting to misalignment, while clutches control power engagement by friction or mechanical interlocking to start or stop motion.

Power interruption

Couplings provide continuous power transmission without interruption, while clutches enable controlled power interruption by engaging or disengaging the drive.

Backlash minimization

Backlash minimization in couplings is typically achieved through zero-backlash designs such as disc or gear couplings, whereas clutches inherently allow controlled slippage, making precise backlash reduction less common.

Overload protection

Couplings provide basic mechanical connection with limited overload protection, while clutches offer advanced overload protection by disengaging the drive to prevent damage during torque spikes.

Flexible coupling

Flexible couplings absorb misalignment and vibration between rotating shafts, providing smoother torque transmission compared to clutches, which primarily engage and disengage power flow.

Friction clutch

Friction clutches transmit torque by engaging two rotating components through friction material, offering smooth power transfer and controlled slip compared to rigid couplings.

Jaw coupling

Jaw couplings provide reliable torque transmission by using interlocking jaws and an elastomeric spider to dampen vibrations and accommodate misalignment, making them superior in flexibility and maintenance compared to traditional clutches.

couplings vs clutches Infographic

njnir.com

njnir.com