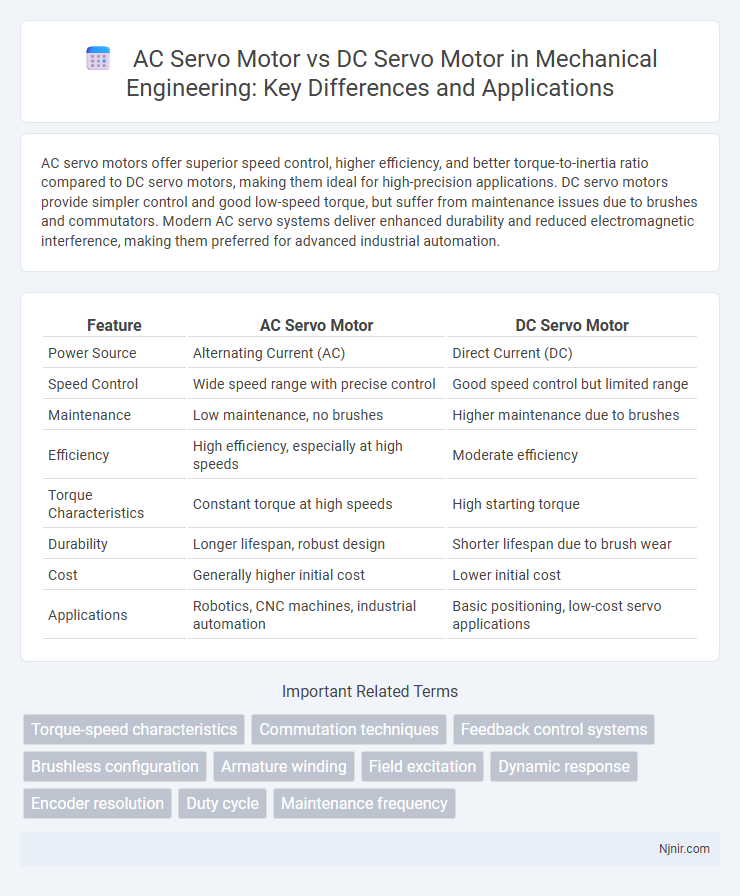

AC servo motors offer superior speed control, higher efficiency, and better torque-to-inertia ratio compared to DC servo motors, making them ideal for high-precision applications. DC servo motors provide simpler control and good low-speed torque, but suffer from maintenance issues due to brushes and commutators. Modern AC servo systems deliver enhanced durability and reduced electromagnetic interference, making them preferred for advanced industrial automation.

Table of Comparison

| Feature | AC Servo Motor | DC Servo Motor |

|---|---|---|

| Power Source | Alternating Current (AC) | Direct Current (DC) |

| Speed Control | Wide speed range with precise control | Good speed control but limited range |

| Maintenance | Low maintenance, no brushes | Higher maintenance due to brushes |

| Efficiency | High efficiency, especially at high speeds | Moderate efficiency |

| Torque Characteristics | Constant torque at high speeds | High starting torque |

| Durability | Longer lifespan, robust design | Shorter lifespan due to brush wear |

| Cost | Generally higher initial cost | Lower initial cost |

| Applications | Robotics, CNC machines, industrial automation | Basic positioning, low-cost servo applications |

Introduction to Servo Motors in Mechanical Engineering

Servo motors in mechanical engineering are crucial for precise motion control, with AC and DC variants serving distinct roles based on application demands. AC servo motors offer high efficiency, greater speed range, and smoother operation due to their alternating current design, making them ideal for industrial automation and robotics. DC servo motors provide excellent torque at low speeds and simpler control mechanisms, often preferred in applications requiring precise position control and quick dynamic response.

Fundamental Principles of AC and DC Servo Motors

AC servo motors operate on alternating current using electromagnetic induction to create a rotating magnetic field, which drives the rotor with precise speed and position control. DC servo motors rely on direct current supplied to a commutator and brushes system that generates a consistent magnetic field, enabling accurate torque and speed regulation. The fundamental difference lies in AC motors using stator windings and synchronous control while DC motors depend on rotor windings and mechanical commutation for motion control.

Construction and Design Differences

AC servo motors feature a stator with three-phase windings and a rotor equipped with permanent magnets or squirrel-cage design, enabling efficient high-speed operation and precise control. DC servo motors consist of a stator with field windings or permanent magnets and a rotor with a commutator and brushes, allowing for straightforward speed regulation but requiring more maintenance due to brush wear. The construction differences lead to AC servo motors being more compact, robust, and suitable for demanding industrial applications, while DC servo motors offer simpler design and easier torque control.

Working Mechanism: AC vs DC Servo Motors

AC servo motors operate using alternating current to create a rotating magnetic field that drives the rotor, enabling precise speed and position control through feedback systems. DC servo motors work by supplying direct current to the stator and rotor, generating torque via electromagnetic interaction for accurate motion control. The AC servo motor's working mechanism offers higher efficiency and better speed regulation, while DC servo motors provide simpler control and faster response times.

Performance Characteristics Comparison

AC servo motors deliver higher efficiency and superior speed regulation due to their advanced feedback control and electronic commutation, making them ideal for precision applications. DC servo motors offer excellent torque at low speeds and simpler speed control, benefiting tasks requiring smooth startup and stall torque. AC motors generally have a longer lifespan and lower maintenance demands compared to the brushed components of DC servo motors.

Control Methods and Feedback Systems

AC servo motors utilize vector control or field-oriented control (FOC) techniques to achieve precise torque and speed regulation, relying heavily on encoders or resolvers for accurate position and velocity feedback. DC servo motors typically implement simpler control methods using pulse-width modulation (PWM) and rely on tachometers or optical encoders for feedback to maintain desired performance characteristics. The advanced feedback systems in AC servo motors provide superior dynamic response and efficiency compared to the often more straightforward control and feedback mechanisms in DC servo setups.

Efficiency and Power Consumption Analysis

AC servo motors generally offer higher efficiency and lower power consumption compared to DC servo motors due to their advanced inverter-driven control systems and reduced mechanical wear. The absence of brushes in AC servo motors eliminates friction losses, contributing to improved energy savings and longer service life. In contrast, DC servo motors exhibit higher power loss because of brush and commutator friction, making them less efficient for high-demand industrial applications.

Applications in Mechanical Engineering Systems

AC servo motors are preferred in mechanical engineering systems requiring high precision, such as CNC machines, robotics, and automated assembly lines, due to their superior speed control and torque capabilities. DC servo motors are commonly used in applications needing simple control and quick response, like conveyor belts, small-scale automation, and position control systems. The choice between AC and DC servo motors depends on factors like system complexity, required accuracy, and maintenance considerations.

Advantages and Limitations of Each Type

AC servo motors offer superior speed control, higher efficiency, and better heat dissipation, making them ideal for high-precision industrial applications. DC servo motors provide excellent torque at low speeds and easier control, but they require regular maintenance due to brush wear and have a limited lifespan. While AC servo motors are more complex and costly, their reliability and lower maintenance needs often outweigh these limitations compared to DC servo motors.

Selection Criteria for AC vs DC Servo Motors

Selection criteria for AC vs DC servo motors hinge on factors like torque requirements, speed range, and maintenance preferences. AC servo motors excel in applications demanding high-speed performance, better heat dissipation, and low maintenance due to brushless design. DC servo motors offer precise control at low speeds and higher starting torque but require more maintenance because of brushes and commutators.

Torque-speed characteristics

AC servo motors provide consistent torque over a wide speed range with efficient performance at high speeds, while DC servo motors deliver high starting torque with relatively lower speed capabilities but excellent low-speed control.

Commutation techniques

AC servo motors use electronic commutation via inverter-driven control signals, while DC servo motors rely on mechanical commutation through brushes and a commutator.

Feedback control systems

AC servo motors offer higher precision and smoother operation in feedback control systems due to advanced encoder integration and superior torque response compared to DC servo motors.

Brushless configuration

Brushless AC servo motors offer higher efficiency, reduced maintenance, and better speed control compared to brushless DC servo motors in precision automation applications.

Armature winding

AC servo motors feature armature windings designed for alternating current with enhanced thermal management, while DC servo motors utilize armature windings optimized for direct current with commutators for efficient torque control.

Field excitation

AC servo motors use alternating current with electromagnetic field excitation controlled by inverters, while DC servo motors rely on direct current and permanent magnets or separate field coils for field excitation.

Dynamic response

AC servo motors exhibit faster dynamic response and higher precision in speed control compared to DC servo motors due to their advanced electronic commutation and feedback systems.

Encoder resolution

AC servo motors typically offer higher encoder resolution than DC servo motors, enabling more precise position feedback and smoother control in advanced automation systems.

Duty cycle

AC servo motors typically offer higher duty cycles and better thermal management compared to DC servo motors, making them more suitable for continuous operation in industrial applications.

Maintenance frequency

AC servo motors generally require less frequent maintenance than DC servo motors due to their brushless design and fewer mechanical wear components.

AC servo motor vs DC servo motor Infographic

njnir.com

njnir.com