Supercritical CO2 cycles exhibit higher thermal efficiency and reduced turbine size compared to traditional Rankine cycles, making them ideal for advanced power generation systems. These cycles operate at higher pressures and temperatures, enhancing heat transfer and minimizing energy losses. Their compact components and improved performance contribute to lower operational costs and reduced environmental impact.

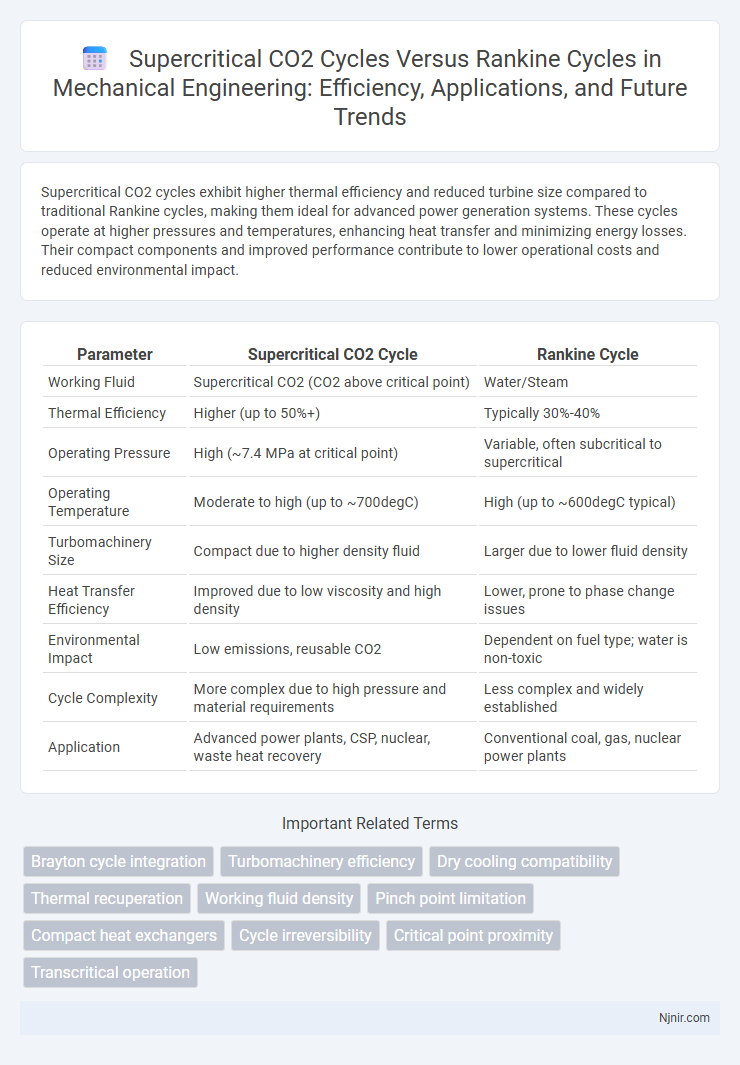

Table of Comparison

| Parameter | Supercritical CO2 Cycle | Rankine Cycle |

|---|---|---|

| Working Fluid | Supercritical CO2 (CO2 above critical point) | Water/Steam |

| Thermal Efficiency | Higher (up to 50%+) | Typically 30%-40% |

| Operating Pressure | High (~7.4 MPa at critical point) | Variable, often subcritical to supercritical |

| Operating Temperature | Moderate to high (up to ~700degC) | High (up to ~600degC typical) |

| Turbomachinery Size | Compact due to higher density fluid | Larger due to lower fluid density |

| Heat Transfer Efficiency | Improved due to low viscosity and high density | Lower, prone to phase change issues |

| Environmental Impact | Low emissions, reusable CO2 | Dependent on fuel type; water is non-toxic |

| Cycle Complexity | More complex due to high pressure and material requirements | Less complex and widely established |

| Application | Advanced power plants, CSP, nuclear, waste heat recovery | Conventional coal, gas, nuclear power plants |

Introduction to Power Generation Cycles

Supercritical CO2 cycles operate at pressures and temperatures above CO2's critical point, enabling higher thermal efficiencies compared to traditional Rankine cycles, which utilize phase changes between liquid and vapor states. The compactness and rapid heat transfer properties of supercritical CO2 enhance turbine performance and reduce system size in power generation applications. Rankine cycles remain widely used due to their established technology and adaptability with various working fluids, but supercritical CO2 cycles offer promising advancements for next-generation power plants aiming for reduced emissions and improved fuel utilization.

Fundamentals of Rankine Cycle

The Rankine cycle operates by converting heat into mechanical work through phase changes of a working fluid, typically water, involving four stages: pressurization in a pump, heating and vaporization in a boiler, expansion in a turbine, and condensation. This thermodynamic cycle relies on the latent heat of vaporization to efficiently generate steam, making it fundamental in conventional power plants such as coal, nuclear, and geothermal. The cycle's efficiency is bounded by boiler pressure and temperature limits, which are generally lower than those achievable in supercritical CO2 cycles, affecting overall thermal efficiency.

Basics of Supercritical CO₂ Cycles

Supercritical CO2 cycles operate above the critical point of carbon dioxide, typically around 31.1degC and 7.38 MPa, allowing the fluid to exhibit unique thermodynamic properties that enhance heat transfer and reduce compression work. These cycles utilize a single-phase working fluid without phase change, leading to higher thermal efficiencies compared to traditional Rankine cycles, which rely on phase transitions between liquid and vapor. The compactness of turbomachinery and reduced environmental impact due to CO2's non-toxic, non-flammable nature make supercritical CO2 cycles advantageous for power generation and waste heat recovery applications.

Thermodynamic Efficiency Comparison

Supercritical CO2 cycles operate at higher temperatures and pressures, allowing for greater thermal efficiency compared to traditional Rankine cycles, which are limited by the boiling point of the working fluid. The supercritical CO2's compact turbomachinery and lower compression work contribute to reduced energy losses and improved cycle performance. Experimental and simulation studies report efficiency improvements of up to 10-15% in power generation applications, making supercritical CO2 cycles a promising alternative for next-generation thermal power plants.

Working Fluid Properties and Selection

Supercritical CO2 cycles utilize carbon dioxide above its critical point (31.1degC, 7.38 MPa), offering high fluid density and low viscosity that enhance heat transfer and reduce compressor work, resulting in improved thermal efficiency compared to Rankine cycles. Rankine cycles typically employ water or organic fluids with phase change characteristics that dictate turbine design and operating conditions but suffer from lower efficiencies at high temperatures due to fluid properties like higher specific volume and viscosity. The selection of supercritical CO2 as a working fluid leverages its favorable thermophysical properties, such as near-isothermal compression and high thermal conductivity, which contribute to compact, cost-effective, and high-efficiency power cycles beyond the constraints of traditional Rankine fluids.

Equipment Design and Material Considerations

Supercritical CO2 cycles operate at higher pressures and temperatures compared to traditional Rankine cycles, requiring advanced materials with superior strength and corrosion resistance to withstand extreme conditions. Equipment design for supercritical CO2 systems emphasizes compact heat exchangers and turbomachinery optimized for dense fluid properties, resulting in smaller, more efficient components. In contrast, Rankine cycle equipment typically uses conventional steam turbines and large boilers with materials suited for lower pressure and temperature ranges, influencing the overall system size and maintenance requirements.

Environmental Impact and Sustainability

Supercritical CO2 cycles offer higher thermal efficiency and reduced water consumption compared to traditional Rankine cycles, leading to lower greenhouse gas emissions and a smaller environmental footprint. These cycles enable more efficient use of renewable and low-carbon energy sources, enhancing overall sustainability in power generation. The compact design and reduced material requirements of supercritical CO2 systems further minimize resource depletion and landfill waste relative to conventional Rankine cycle plants.

Operational Flexibility and Scalability

Supercritical CO2 cycles offer superior operational flexibility with rapid startup and shutdown capabilities, enabling efficient load-following and integration with renewable energy sources compared to traditional Rankine cycles. Their compact turbine and lower working fluid volume enhance scalability for smaller modular power plants, facilitating deployment in diverse applications from waste heat recovery to concentrated solar power. In contrast, Rankine cycles usually require longer startup times and larger equipment footprints, limiting their adaptability and scalability in dynamic operational environments.

Economic Analysis and Cost Implications

Supercritical CO2 cycles offer higher thermal efficiency and reduced component size, leading to lower capital costs compared to traditional Rankine cycles. The compactness and simplified heat exchangers in supercritical CO2 systems translate into reduced material and maintenance expenses, improving the overall economic viability. Despite higher initial technology costs, the improved performance and reduced operational expenditures make supercritical CO2 cycles more cost-effective over the lifespan of power generation projects.

Future Trends in Advanced Power Cycles

Supercritical CO2 cycles exhibit higher thermal efficiency and compact system design compared to traditional Rankine cycles, making them promising candidates for next-generation power plants. Emerging research focuses on enhancing material durability and optimizing turbomachinery to leverage the favorable thermo-physical properties of supercritical CO2 at elevated pressures and temperatures. Increased integration with renewable energy sources and waste heat recovery systems highlights the potential of supercritical CO2 cycles to drive sustainable and flexible power generation solutions.

Brayton cycle integration

Supercritical CO2 cycles integrated with Brayton cycles achieve higher thermal efficiency and reduced turbine size compared to traditional Rankine cycles by operating at elevated pressures and temperatures.

Turbomachinery efficiency

Supercritical CO2 cycles achieve higher turbomachinery efficiency than Rankine cycles due to CO2's superior thermophysical properties, enabling compact, high-speed compressors and turbines with reduced aerodynamic losses.

Dry cooling compatibility

Supercritical CO2 cycles demonstrate superior dry cooling compatibility compared to Rankine cycles due to higher thermal efficiency and reduced water consumption in arid environments.

Thermal recuperation

Supercritical CO2 cycles achieve higher thermal recuperation efficiency than Rankine cycles by utilizing compact, high-effectiveness heat exchangers that recover more waste heat and operate at elevated pressures and temperatures.

Working fluid density

Supercritical CO2 cycles exhibit significantly higher working fluid density than Rankine cycles, enabling more compact turbomachinery and improved heat transfer efficiency.

Pinch point limitation

Supercritical CO2 cycles achieve higher thermal efficiency than Rankine cycles by minimizing pinch point temperature differences, enabling better heat transfer and reduced exergy losses in heat exchangers.

Compact heat exchangers

Supercritical CO2 cycles utilize compact heat exchangers with higher heat transfer efficiency and smaller footprint compared to traditional Rankine cycle heat exchangers, enabling improved thermal performance and reduced system size.

Cycle irreversibility

Supercritical CO2 cycles exhibit lower cycle irreversibility compared to Rankine cycles due to reduced thermodynamic losses and higher heat transfer efficiency near the critical point.

Critical point proximity

Supercritical CO2 cycles operate near the CO2 critical point at 31.1degC and 7.38 MPa, enabling higher thermal efficiency and compact system design compared to Rankine cycles that function below critical conditions.

Transcritical operation

Supercritical CO2 cycles operate above the CO2 critical point, enabling higher thermal efficiencies and compact turbomachinery compared to traditional Rankine cycles, while transcritical operation in Rankine cycles involves crossing the fluid's critical pressure and temperature, enhancing heat transfer but typically resulting in lower efficiencies and larger system sizes.

Supercritical CO2 cycles vs Rankine cycles Infographic

njnir.com

njnir.com