Alloy steel contains additional elements such as chromium, nickel, and molybdenum, enhancing its strength, toughness, and corrosion resistance compared to carbon steel, which primarily consists of iron and carbon. Carbon steel is typically more cost-effective and easier to machine, making it suitable for general-purpose applications, whereas alloy steel is preferred for high-stress environments demanding improved mechanical properties. The choice between alloy and carbon steel depends on the balance required between performance, durability, and budget constraints in mechanical engineering projects.

Table of Comparison

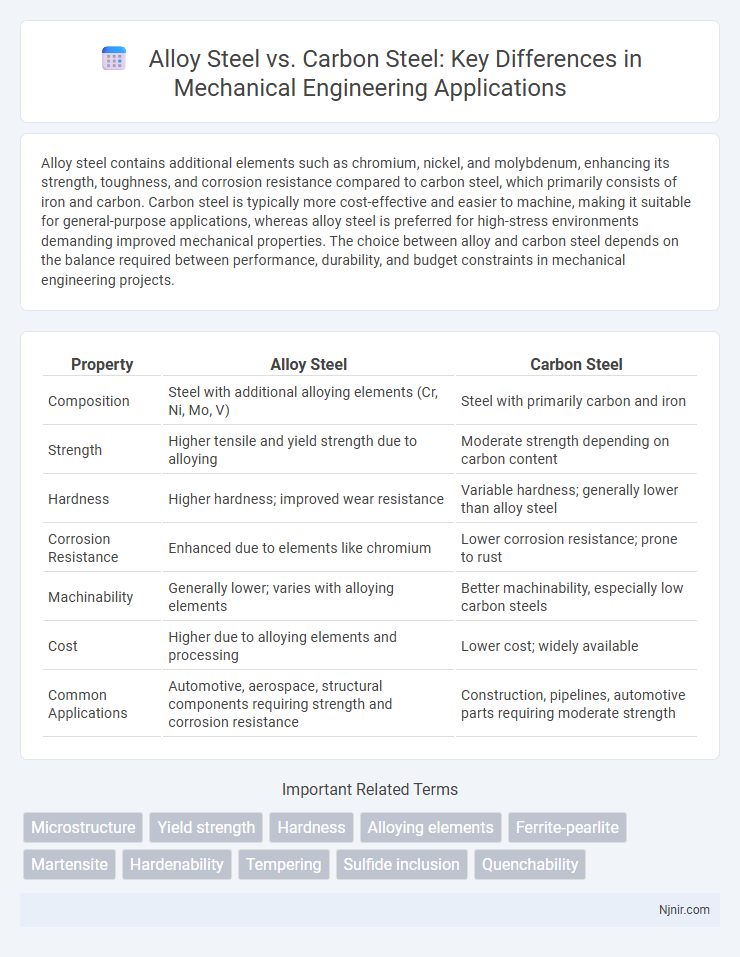

| Property | Alloy Steel | Carbon Steel |

|---|---|---|

| Composition | Steel with additional alloying elements (Cr, Ni, Mo, V) | Steel with primarily carbon and iron |

| Strength | Higher tensile and yield strength due to alloying | Moderate strength depending on carbon content |

| Hardness | Higher hardness; improved wear resistance | Variable hardness; generally lower than alloy steel |

| Corrosion Resistance | Enhanced due to elements like chromium | Lower corrosion resistance; prone to rust |

| Machinability | Generally lower; varies with alloying elements | Better machinability, especially low carbon steels |

| Cost | Higher due to alloying elements and processing | Lower cost; widely available |

| Common Applications | Automotive, aerospace, structural components requiring strength and corrosion resistance | Construction, pipelines, automotive parts requiring moderate strength |

Composition Differences Between Alloy Steel and Carbon Steel

Alloy steel contains significant amounts of alloying elements such as chromium, nickel, molybdenum, and vanadium, which enhance mechanical properties like strength, hardness, and corrosion resistance compared to carbon steel. Carbon steel primarily consists of iron and carbon, with carbon content typically ranging from 0.02% to 2.1%, and minimal other alloying elements. The presence and proportion of these alloying elements in alloy steel result in a wider range of grades and applications tailored to specific performance requirements.

Mechanical Properties Comparison

Alloy steel exhibits superior mechanical properties compared to carbon steel, including higher tensile strength, enhanced hardness, and improved wear resistance due to the addition of elements like chromium, nickel, and molybdenum. Carbon steel generally offers good strength and ductility but lacks the enhanced toughness and corrosion resistance found in alloy steels. These mechanical advantages make alloy steel preferable for high-stress applications such as aerospace, automotive, and heavy machinery components.

Applications in Mechanical Engineering

Alloy steel is preferred in mechanical engineering for high-stress applications like gears, shafts, and turbine blades due to its enhanced strength, toughness, and resistance to wear and corrosion. Carbon steel is commonly used for structural components, automotive parts, and machinery frames because of its excellent hardness and affordability. Both materials are selected based on specific mechanical requirements and environmental conditions to optimize performance and durability.

Strength and Durability Factors

Alloy steel offers superior strength and durability compared to carbon steel due to the addition of elements such as chromium, nickel, and molybdenum, which enhance hardness, tensile strength, and resistance to wear and corrosion. Carbon steel, while generally less expensive, exhibits lower tensile strength and is more susceptible to rust and fatigue under harsh conditions. The metallurgical composition of alloy steel makes it ideal for high-stress applications requiring long-lasting performance and resistance to mechanical and environmental degradation.

Corrosion Resistance Analysis

Alloy steel exhibits superior corrosion resistance compared to carbon steel due to the inclusion of elements such as chromium, nickel, and molybdenum, which form a protective oxide layer on the surface. Carbon steel lacks these alloying elements, making it more susceptible to rust and degradation in harsh environments. The enhanced corrosion resistance of alloy steel extends the lifespan of components in chemical, marine, and industrial applications.

Cost Considerations and Economic Impact

Alloy steel typically incurs higher costs than carbon steel due to the addition of elements like chromium, nickel, and molybdenum, which enhance strength, corrosion resistance, and durability. While the initial investment is greater, alloy steel often results in lower maintenance and replacement expenses, improving long-term economic efficiency in applications with demanding performance requirements. Carbon steel remains a more cost-effective option for projects with less stringent mechanical properties and environmental conditions, reducing upfront material costs.

Weldability and Machinability

Alloy steel generally offers improved weldability compared to carbon steel due to its controlled chemical composition, which reduces weld cracking and allows for better joint strength. The machinability of alloy steel varies based on alloying elements, often requiring specialized tooling and slower cutting speeds, whereas carbon steel typically provides easier machining with higher cutting speeds and less tool wear. Welding carbon steel is simpler, making it preferred for basic structural applications, but alloy steel's enhanced mechanical properties justify its more complex machining and welding processes in high-performance environments.

Heat Treatment Capabilities

Alloy steel exhibits superior heat treatment capabilities compared to carbon steel due to its varied alloying elements like chromium, nickel, and molybdenum, which enhance hardenability, strength, and toughness. Heat treatment processes such as quenching and tempering are more effective in alloy steels, allowing precise control over mechanical properties and improved resistance to wear and fatigue. Carbon steel heat treatment primarily increases hardness and strength but lacks the extensive performance benefits provided by the complex metallurgy of alloy steels.

Common Grades and Standards

Alloy steel commonly includes grades such as 4140, 4340, and 8620, adhering to standards like ASTM A681 and SAE J403, known for enhanced mechanical properties and corrosion resistance. Carbon steel grades such as A36, AISI 1018, and 1045 follow ASTM A36 and SAE J403 standards, primarily offering high strength and wear resistance. Selection between these steels depends on specific application requirements involving toughness, hardness, and exposure to environmental factors.

Environmental Impact and Sustainability

Alloy steel generally has a higher environmental impact than carbon steel due to its complex production processes and use of additional alloying elements that require extensive mining and refining. Carbon steel, with its simpler composition, tends to be more recyclable and has lower energy consumption during manufacturing, contributing to better sustainability profiles. Efficient recycling of both steels reduces landfill waste, but carbon steel's widespread recyclability and lower processing energy make it more favorable for eco-friendly applications.

Microstructure

Alloy steel features a complex microstructure with alloying elements like chromium and nickel enhancing hardness and corrosion resistance, while carbon steel primarily consists of ferrite and pearlite phases influencing its strength and ductility.

Yield strength

Alloy steel typically exhibits higher yield strength than carbon steel due to its enhanced composition of elements like chromium, nickel, and molybdenum.

Hardness

Alloy steel exhibits higher hardness than carbon steel due to the presence of additional alloying elements like chromium, nickel, and molybdenum that enhance its strength and wear resistance.

Alloying elements

Alloy steel contains significant amounts of alloying elements such as chromium, nickel, and molybdenum to enhance strength and corrosion resistance, while carbon steel primarily relies on carbon content with minimal additional elements.

Ferrite-pearlite

Alloy steel contains added elements that refine the ferrite-pearlite microstructure, enhancing strength and hardness compared to the predominantly ferrite-pearlite carbon steel.

Martensite

Martensite in alloy steel typically exhibits enhanced hardness and wear resistance compared to carbon steel due to the presence of alloying elements like chromium and molybdenum that refine its microstructure.

Hardenability

Alloy steel exhibits superior hardenability compared to carbon steel due to its enhanced alloying elements like chromium, molybdenum, and nickel that improve depth and uniformity of hardness during heat treatment.

Tempering

Alloy steel exhibits enhanced tempering properties compared to carbon steel, resulting in superior toughness and resistance to wear and fatigue.

Sulfide inclusion

Alloy steel typically exhibits improved resistance to sulfide inclusion defects compared to carbon steel due to the presence of elements like chromium and manganese that enhance sulfide morphology and distribution.

Quenchability

Alloy steel exhibits superior quenchability compared to carbon steel due to its enhanced hardenability from added alloying elements like chromium, molybdenum, and manganese.

Alloy steel vs carbon steel Infographic

njnir.com

njnir.com