Direct metal laser sintering (DMLS) offers higher resolution and finer detail in producing complex geometries compared to electron beam melting (EBM), making it ideal for applications requiring precision. While EBM operates in a vacuum and enables faster build rates with lower residual stress, DMLS uses a laser in an inert gas environment, resulting in superior surface finish and material density. Both methods enhance mechanical properties by achieving near-full density, but DMLS is often preferred for aerospace and medical components requiring tight tolerances and intricate designs.

Table of Comparison

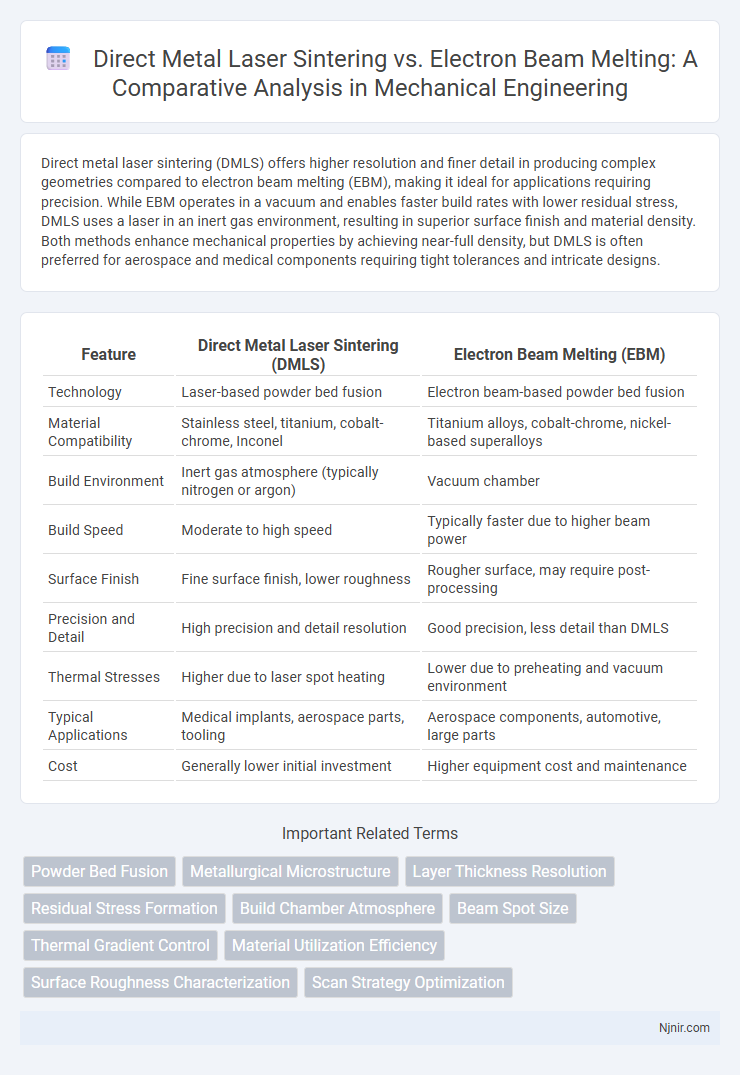

| Feature | Direct Metal Laser Sintering (DMLS) | Electron Beam Melting (EBM) |

|---|---|---|

| Technology | Laser-based powder bed fusion | Electron beam-based powder bed fusion |

| Material Compatibility | Stainless steel, titanium, cobalt-chrome, Inconel | Titanium alloys, cobalt-chrome, nickel-based superalloys |

| Build Environment | Inert gas atmosphere (typically nitrogen or argon) | Vacuum chamber |

| Build Speed | Moderate to high speed | Typically faster due to higher beam power |

| Surface Finish | Fine surface finish, lower roughness | Rougher surface, may require post-processing |

| Precision and Detail | High precision and detail resolution | Good precision, less detail than DMLS |

| Thermal Stresses | Higher due to laser spot heating | Lower due to preheating and vacuum environment |

| Typical Applications | Medical implants, aerospace parts, tooling | Aerospace components, automotive, large parts |

| Cost | Generally lower initial investment | Higher equipment cost and maintenance |

Introduction to Additive Manufacturing in Mechanical Engineering

Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM) are pivotal additive manufacturing techniques in mechanical engineering, utilizing layer-by-layer fusion of metal powders to create complex geometries with high precision. DMLS employs a high-powered laser to sinter metal particles in an inert gas environment, offering finer surface finish and higher resolution for aerospace and medical components. EBM uses an electron beam in a vacuum to melt metal powders, enabling faster build rates and superior mechanical properties in titanium alloys, often preferred for aerospace structural parts due to its strong metallurgical bonds and reduced residual stress.

Overview of Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is an additive manufacturing technique that uses a high-powered laser to fuse fine metal powders into solid structures layer by layer. This process allows for complex geometries and high precision in producing intricate metal parts, commonly used in aerospace, medical, and automotive industries. DMLS offers advantages in material efficiency, reduced lead times, and the ability to work with a wide range of metal alloys such as titanium, stainless steel, and aluminum.

Overview of Electron Beam Melting (EBM)

Electron Beam Melting (EBM) is an additive manufacturing process that uses a high-energy electron beam to selectively melt metal powder in a vacuum environment, producing fully dense metal parts with excellent mechanical properties. EBM primarily works with titanium alloys, cobalt-chrome, and other high-performance metals, offering faster build rates and reduced residual stresses compared to Direct Metal Laser Sintering (DMLS). The vacuum environment in EBM minimizes oxidation and contamination, making it highly suitable for aerospace and medical implant applications requiring exceptional material purity and strength.

Material Compatibility in DMLS and EBM

Direct Metal Laser Sintering (DMLS) supports a wide range of materials including stainless steel, aluminum, titanium alloys, and cobalt-chrome, enabling versatile applications in aerospace, medical, and automotive industries. Electron Beam Melting (EBM) is predominantly compatible with high-value alloys such as titanium and its composites due to its vacuum environment, which reduces oxidation and enhances mechanical properties. Material compatibility in DMLS is broader and suited for complex geometries, whereas EBM excels in producing dense, high-strength components from specialized titanium alloys.

Process Parameters and Energy Sources

Direct Metal Laser Sintering (DMLS) utilizes a high-powered laser beam as its energy source, precisely melting metal powder layer by layer with controlled laser power, scan speed, and hatch spacing to optimize part density and surface finish. Electron Beam Melting (EBM) employs an electron beam in a vacuum environment, with adjustable beam current, voltage, and scan pattern to selectively melt metal powder at higher energy densities, resulting in reduced residual stresses and improved mechanical properties. Process parameters in DMLS favor finer feature resolution due to localized laser melting, whereas EBM's energy source enables faster build rates and better handling of reactive materials like titanium alloys.

Surface Finish and Dimensional Accuracy Comparison

Direct Metal Laser Sintering (DMLS) typically achieves finer surface finishes with layer thicknesses around 20-40 microns, resulting in smoother parts and less post-processing compared to Electron Beam Melting (EBM), which often produces rougher surfaces due to higher energy and powder granularity. Dimensional accuracy in DMLS usually ranges within +-0.1 mm, offering tighter tolerances ideal for intricate components, whereas EBM parts exhibit slightly lower precision, around +-0.2 mm, caused by electron beam scattering and thermal gradients. Surface roughness (Ra) values for DMLS average between 5-15 microns, while EBM surfaces can have roughness exceeding 15 microns, influencing the choice of process based on final application requirements.

Mechanical Properties of DMLS vs EBM Parts

Direct Metal Laser Sintering (DMLS) typically produces parts with higher tensile strength and better surface finish compared to Electron Beam Melting (EBM), due to its finer laser beam and lower thermal input. DMLS parts often exhibit superior hardness and fatigue resistance, which are critical for aerospace and medical applications. EBM parts, however, benefit from reduced residual stress and improved ductility because of the high build temperatures and vacuum environment used during processing.

Build Speed and Production Scalability

Direct Metal Laser Sintering (DMLS) offers faster build speeds due to its high-powered laser selectively fusing metal powder layer by layer, making it suitable for rapid prototyping and moderate-scale production. Electron Beam Melting (EBM) generally operates at slower build speeds because of its electron beam scanning process, but it excels in production scalability by enabling larger build volumes and efficient powder reuse in vacuum environments. Both technologies support scalable manufacturing; however, DMLS is preferred for quicker turnaround times, whereas EBM is favored for producing larger, complex parts with improved material properties.

Cost Considerations for DMLS and EBM

Direct Metal Laser Sintering (DMLS) typically incurs higher operational costs due to the extensive use of high-power lasers and inert gas environments, while Electron Beam Melting (EBM) demands significant investment in vacuum systems and electron beam technology. Material costs for EBM are generally elevated because of the need for vacuum-compatible powders, which are often more expensive than those used in DMLS. Maintenance expenses for EBM machines are also higher, attributed to the complexity of electron beam components and vacuum chambers, impacting the overall cost-efficiency compared to DMLS.

Industrial Applications and Use Cases

Direct Metal Laser Sintering (DMLS) excels in producing complex, high-precision parts with fine detail, making it ideal for aerospace components, medical implants, and intricate automotive parts. Electron Beam Melting (EBM) offers faster build rates and superior mechanical properties, favored in the production of high-strength orthopedic implants and large-scale aerospace structural components. Both technologies enable the fabrication of custom, lightweight metal parts but differ in energy sources, build environments, and material compatibility, influencing their specific industrial applications.

Powder Bed Fusion

Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM) are Powder Bed Fusion techniques distinguished by DMLS using a laser to fuse metal powder layer-by-layer for high-resolution, complex geometries, while EBM employs an electron beam in a vacuum environment, offering faster build rates and reduced residual stress in high-performance aerospace and medical implants.

Metallurgical Microstructure

Direct metal laser sintering produces finer, more homogeneous metallurgical microstructures with rapid solidification, whereas electron beam melting yields coarser grains and higher residual stresses due to slower cooling rates.

Layer Thickness Resolution

Direct Metal Laser Sintering (DMLS) typically achieves a finer layer thickness resolution of 20-40 microns, whereas Electron Beam Melting (EBM) generally operates with thicker layers around 50-100 microns, impacting the surface detail and accuracy of printed metal parts.

Residual Stress Formation

Direct Metal Laser Sintering generates higher residual stresses due to rapid cooling and localized heating compared to Electron Beam Melting, which uses a preheated powder bed to reduce thermal gradients and minimize residual stress formation.

Build Chamber Atmosphere

Direct Metal Laser Sintering operates in an inert gas atmosphere to prevent oxidation, while Electron Beam Melting requires a high vacuum build chamber for process stability and material integrity.

Beam Spot Size

Direct Metal Laser Sintering features a smaller beam spot size typically ranging from 30 to 100 microns, enabling higher precision and fine detail, whereas Electron Beam Melting uses a larger beam spot size around 100 to 200 microns, resulting in faster build rates but slightly lower resolution.

Thermal Gradient Control

Direct Metal Laser Sintering offers precise thermal gradient control through rapid localized laser melting, whereas Electron Beam Melting utilizes a high-energy electron beam in a vacuum to achieve deeper thermal penetration and more uniform heat distribution.

Material Utilization Efficiency

Direct metal laser sintering achieves higher material utilization efficiency than electron beam melting by minimizing powder recycling and enabling precise layer-by-layer fabrication.

Surface Roughness Characterization

Direct metal laser sintering typically produces parts with higher surface roughness averaging 8-12 micrometers, while electron beam melting achieves smoother surfaces around 4-7 micrometers due to its higher build temperatures and vacuum environment.

Scan Strategy Optimization

Scan strategy optimization in direct metal laser sintering enhances precision and surface finish by adjusting laser path patterns, while in electron beam melting it improves build efficiency and thermal management through electron beam trajectory control.

direct metal laser sintering vs electron beam melting Infographic

njnir.com

njnir.com