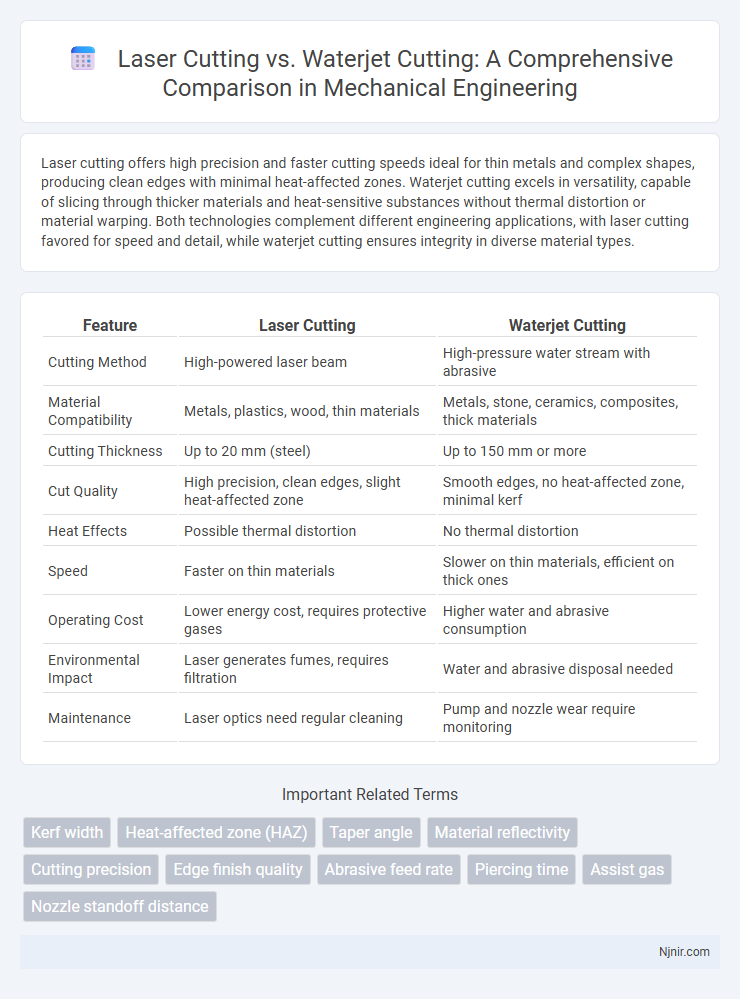

Laser cutting offers high precision and faster cutting speeds ideal for thin metals and complex shapes, producing clean edges with minimal heat-affected zones. Waterjet cutting excels in versatility, capable of slicing through thicker materials and heat-sensitive substances without thermal distortion or material warping. Both technologies complement different engineering applications, with laser cutting favored for speed and detail, while waterjet cutting ensures integrity in diverse material types.

Table of Comparison

| Feature | Laser Cutting | Waterjet Cutting |

|---|---|---|

| Cutting Method | High-powered laser beam | High-pressure water stream with abrasive |

| Material Compatibility | Metals, plastics, wood, thin materials | Metals, stone, ceramics, composites, thick materials |

| Cutting Thickness | Up to 20 mm (steel) | Up to 150 mm or more |

| Cut Quality | High precision, clean edges, slight heat-affected zone | Smooth edges, no heat-affected zone, minimal kerf |

| Heat Effects | Possible thermal distortion | No thermal distortion |

| Speed | Faster on thin materials | Slower on thin materials, efficient on thick ones |

| Operating Cost | Lower energy cost, requires protective gases | Higher water and abrasive consumption |

| Environmental Impact | Laser generates fumes, requires filtration | Water and abrasive disposal needed |

| Maintenance | Laser optics need regular cleaning | Pump and nozzle wear require monitoring |

Introduction to Laser Cutting and Waterjet Cutting

Laser cutting employs high-powered laser beams to precisely cut through materials like metals, plastics, and wood by vaporizing or melting the targeted area. Waterjet cutting uses a high-pressure stream of water, sometimes combined with abrasive particles, to erode materials such as stone, metal, and composites without generating heat. Both technologies offer high precision, with laser cutting excelling in speed and intricate detail, while waterjet cutting provides versatile, heat-free processing suitable for a broader range of materials.

Core Principles: How Laser and Waterjet Cutting Work

Laser cutting uses a high-powered laser beam focused on a material to vaporize or melt it, creating precise cuts through intense heat. Waterjet cutting propels a high-pressure stream of water, often mixed with abrasive particles, to erode materials without heat, making it ideal for heat-sensitive substrates. Both methods offer distinct advantages based on material properties and desired cut quality, with laser cutting excelling in speed and precision for thin metals and waterjet providing versatility for thicker or composite materials.

Material Compatibility and Versatility

Laser cutting excels in precision with metals, plastics, and thin materials but struggles with reflective or heat-sensitive substrates. Waterjet cutting offers superior versatility, handling a broader range of materials including metals, stone, glass, and composites without heat distortion. The choice depends on material properties, with waterjet favored for thicker, heat-sensitive, or composite materials and laser cutting preferred for high-precision requirements in thinner metals and plastics.

Precision and Edge Quality Comparison

Laser cutting offers exceptional precision with tolerances often within +-0.1 mm, producing clean edges ideal for intricate designs and thin materials. Waterjet cutting provides excellent edge quality, especially on thicker or heat-sensitive materials, with smooth, burr-free finishes and minimal thermal distortion. The choice depends on material type and thickness, as laser cutting excels in speed and fine detail, while waterjet cutting ensures superior edge integrity on diverse substrates.

Cutting Speed and Efficiency

Laser cutting offers significantly higher cutting speeds compared to waterjet cutting, especially when working with thin metals and non-metallic materials. Waterjet cutting, while slower, excels in cutting thicker materials and is highly efficient for applications requiring minimal thermal distortion and precise edges. Choosing between these methods depends on the material type, thickness, and production volume, with laser cutting favored for fast, high-precision tasks and waterjet cutting preferred for versatility and heat-sensitive materials.

Thickness and Depth Limitations

Laser cutting excels in precision for materials up to approximately 25 mm thick, particularly metals and plastics, but its effectiveness drops significantly with thicker or highly reflective materials. Waterjet cutting offers superior thickness and depth capabilities, handling materials up to 150 mm or more without thermal distortion, making it ideal for stone, metal, and composites. The choice depends on material thickness, with laser cutting optimized for thin to medium thickness and waterjet cutting preferred for heavy-duty, thick materials requiring deep, precise cuts.

Cost Analysis: Equipment, Operation, and Maintenance

Laser cutting equipment generally incurs higher initial investment costs than waterjet machines, with industrial-grade lasers ranging from $50,000 to over $400,000. Operational expenses for laser cutting include substantial electricity consumption and periodic replacement of laser tubes or optics, while waterjet cutting requires continuous supply of abrasive materials and higher water usage costs. Maintenance for laser cutters often involves precise alignment and cleaning of optical components, whereas waterjet systems demand frequent pump servicing and abrasive delivery system upkeep, influencing long-term cost efficiency.

Environmental Impact and Safety Considerations

Laser cutting produces minimal waste and lower emissions compared to waterjet cutting, which uses large volumes of water and abrasive materials, potentially creating contaminated runoff requiring proper disposal. The high-energy laser beams pose risks such as eye damage and fire hazards, necessitating protective measures and ventilation systems, while waterjet cutting involves risks from high-pressure water jets, requiring safeguards to prevent injuries. Both methods demand adherence to safety protocols and environmental regulations, but laser cutting is generally considered more energy-efficient with a smaller ecological footprint.

Typical Applications in Mechanical Engineering

Laser cutting excels in precision machining of thin metals, plastics, and sheet materials, making it ideal for fabricating intricate components and prototypes in mechanical engineering. Waterjet cutting handles thicker, harder materials like steel, titanium, and composites without heat distortion, often used for heavy-duty parts and complex shapes in aerospace and automotive sectors. Both technologies are integral for enhancing manufacturing efficiency and accuracy in producing gears, brackets, and custom machinery parts.

Choosing the Right Cutting Method for Your Project

Laser cutting offers high precision and speed, making it ideal for thin materials like metals, plastics, and wood with intricate designs. Waterjet cutting excels in handling thicker, heat-sensitive materials such as stone, glass, and composites without causing thermal distortion. Selecting the right cutting method depends on factors like material type, thickness, edge quality, and heat sensitivity to ensure optimal results and cost-efficiency.

Kerf width

Laser cutting typically produces a narrower kerf width of 0.1 to 0.3 mm compared to waterjet cutting's wider kerf of 0.8 to 1.2 mm, making laser cutting ideal for precision tasks requiring fine detail.

Heat-affected zone (HAZ)

Laser cutting generally produces a larger heat-affected zone (HAZ) due to concentrated heat, while waterjet cutting minimizes HAZ by using cold abrasive water, preserving material properties.

Taper angle

Laser cutting typically produces a taper angle of around 1-3 degrees due to beam divergence, while waterjet cutting achieves a minimal taper angle often below 0.5 degrees because of its precise abrasive jet stream.

Material reflectivity

Laser cutting efficiency decreases significantly with highly reflective materials like copper and aluminum, whereas waterjet cutting remains unaffected by material reflectivity, making it ideal for reflective metals.

Cutting precision

Laser cutting achieves cutting precision up to 0.1 mm due to its focused beam, while waterjet cutting offers precision around 0.2 mm with minimal material distortion.

Edge finish quality

Laser cutting produces sharper, more precise edges with minimal burrs, while waterjet cutting offers smooth edges with no heat-affected zone, reducing warping and preserving material integrity.

Abrasive feed rate

The abrasive feed rate in waterjet cutting significantly influences cut quality and speed, whereas laser cutting relies on focused light energy, making abrasive feed rate irrelevant to its process efficiency.

Piercing time

Laser cutting pierces materials in milliseconds, significantly faster than waterjet cutting's piercing time of several seconds to minutes, enhancing overall production speed.

Assist gas

Laser cutting uses assist gases like oxygen or nitrogen to enhance cutting speed and quality, while waterjet cutting relies on high-pressure water mixed with abrasives, eliminating the need for assist gases.

Nozzle standoff distance

Laser cutting requires a minimal nozzle standoff distance of 0.5-1.0 mm for optimal precision, whereas waterjet cutting operates effectively with a larger standoff distance of 3-6 mm to maintain jet coherence and material quality.

Laser cutting vs waterjet cutting Infographic

njnir.com

njnir.com