Friction welding creates a solid-state joint by generating heat through mechanical friction, avoiding melting and preserving material properties, while fusion welding melts the base materials to form a joint. Friction welding offers superior strength, minimal distortion, and reduced residual stresses compared to fusion welding, making it ideal for dissimilar metals or heat-sensitive components. Fusion welding provides versatility for complex shapes and is widely used in applications requiring filler material and fusion of similar metals.

Table of Comparison

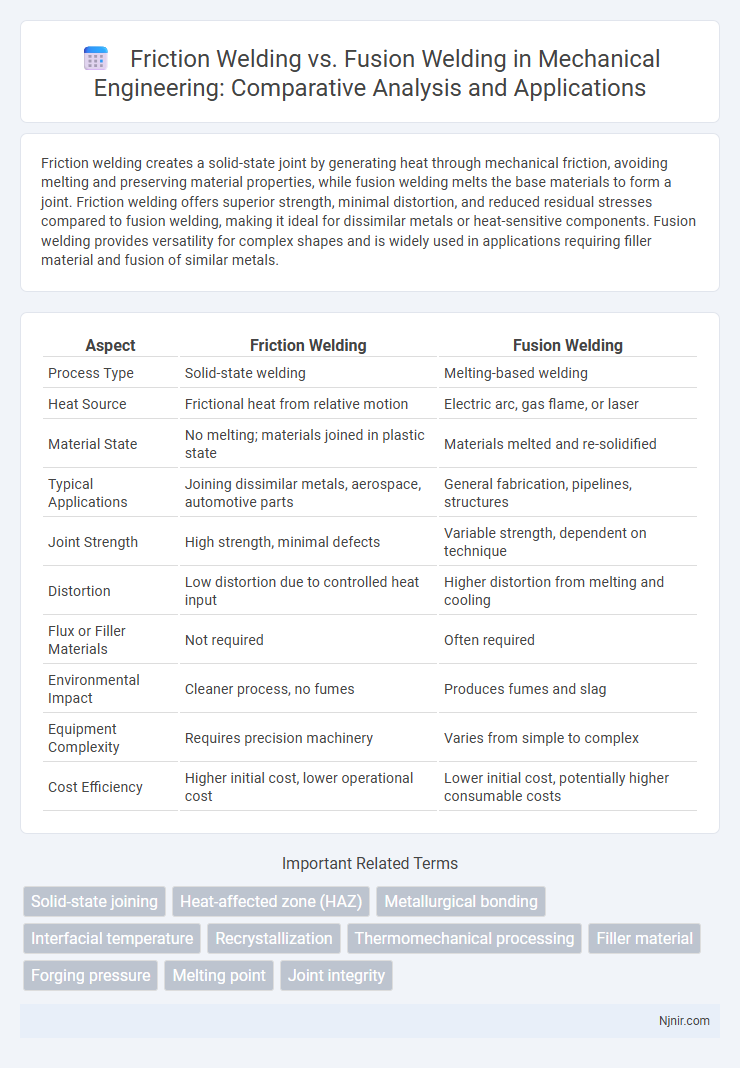

| Aspect | Friction Welding | Fusion Welding |

|---|---|---|

| Process Type | Solid-state welding | Melting-based welding |

| Heat Source | Frictional heat from relative motion | Electric arc, gas flame, or laser |

| Material State | No melting; materials joined in plastic state | Materials melted and re-solidified |

| Typical Applications | Joining dissimilar metals, aerospace, automotive parts | General fabrication, pipelines, structures |

| Joint Strength | High strength, minimal defects | Variable strength, dependent on technique |

| Distortion | Low distortion due to controlled heat input | Higher distortion from melting and cooling |

| Flux or Filler Materials | Not required | Often required |

| Environmental Impact | Cleaner process, no fumes | Produces fumes and slag |

| Equipment Complexity | Requires precision machinery | Varies from simple to complex |

| Cost Efficiency | Higher initial cost, lower operational cost | Lower initial cost, potentially higher consumable costs |

Introduction to Friction Welding and Fusion Welding

Friction welding joins materials by generating heat through mechanical friction, creating a solid-state bond without melting the base metals. Fusion welding involves melting the materials with an external heat source, such as an electric arc or laser, to form a molten pool that solidifies into a joint. Both techniques serve critical roles in manufacturing, with friction welding offering advantages in strength and efficiency, while fusion welding provides versatility for various metals and complex shapes.

Fundamental Principles of Friction Welding

Friction welding joins materials through heat generated by mechanical friction between workpieces without melting the base metals, ensuring a solid-state bond with minimal microstructural changes. This process relies on rotational or linear motion under pressure to create plastic deformation at the interface, which solidifies into a strong joint upon cooling. Unlike fusion welding, which melts and solidifies the metals, friction welding avoids common fusion defects such as porosity and cracking, resulting in superior mechanical properties and metallurgical integrity.

Key Processes in Fusion Welding

Fusion welding involves melting base metals and typically adding a filler material to create a strong joint, with key processes including arc welding, gas welding, and laser welding. Heat source variations such as electric arcs, flames, or lasers facilitate the melting and fusion of metals at the joint interface. This contrasts with friction welding, which joins metals through mechanical heat generated by friction without melting the base materials.

Comparative Analysis: Heat Generation Mechanisms

Friction welding generates heat through mechanical friction between workpieces, creating a solid-state bond without melting the base materials, which preserves the original microstructure and reduces thermal distortion. Fusion welding relies on melting the materials using external heat sources such as electric arcs or gas flames, resulting in a molten pool that solidifies to form the joint but often introduces thermal stresses and metallurgical changes. The controlled heat input in friction welding offers improved joint strength and minimal defects compared to fusion welding, where uneven heat distribution can lead to weld porosity and cracking.

Material Compatibility: Friction vs Fusion Welding

Friction welding offers superior material compatibility by joining dissimilar metals without melting, preserving base material properties and minimizing defects like cracking or distortion. Fusion welding relies on melting and solidification, which can cause metallurgical issues and limit compatibility to similar or carefully matched alloys. This makes friction welding preferable for applications requiring the combination of exotic or highly dissimilar materials.

Joint Strength and Structural Integrity

Friction welding produces joints with superior strength and enhanced structural integrity due to solid-state bonding, minimizing defects such as porosity and cracking common in fusion welding. Fusion welding involves melting and solidification, which can lead to residual stresses and potential weaknesses in the heat-affected zone, compromising joint reliability. The solid-phase process of friction welding ensures consistent mechanical properties and durability, making it preferable for critical load-bearing applications.

Applications in Mechanical Engineering Industries

Friction welding is widely used in the aerospace and automotive industries for joining dissimilar metals and producing high-strength, fatigue-resistant components such as turbine blades and drive shafts. Fusion welding is prevalent in shipbuilding, pipeline construction, and heavy machinery manufacturing, where it allows for the creation of complex joint geometries and thick-section welds using processes like MIG, TIG, and arc welding. Mechanical engineering industries select friction welding for precision assembly and minimal thermal distortion, while fusion welding suits large-scale fabrication and repair operations.

Advantages and Limitations of Each Welding Method

Friction welding offers advantages such as producing high-strength joints with minimal thermal distortion and no filler materials, making it ideal for joining dissimilar metals and complex geometries. Fusion welding enables versatile applications with deep penetration and the ability to easily add filler metals, but it often results in higher heat-affected zones and increased residual stresses. Limitations of friction welding include equipment cost and constraints on part size and shape, while fusion welding's challenges encompass potential defects like porosity and the necessity for post-weld heat treatment to relieve stress.

Quality Control and Inspection Techniques

Friction welding ensures superior joint integrity through controlled heat and pressure, minimizing defects such as porosity and cracks, which enhances the reliability of non-destructive testing (NDT) methods like ultrasonic and radiographic inspection. Fusion welding often requires stringent quality control protocols to detect common issues such as slag inclusion and incomplete fusion, with advanced techniques like phased array ultrasonic testing (PAUT) and digital radiography offering detailed flaw detection. Both processes benefit from real-time monitoring systems and post-weld inspections to maintain consistent weld quality and adherence to industry standards such as ASME and ISO.

Future Trends in Welding Technology

Friction welding is advancing with innovations in automation and real-time monitoring to improve joint quality and reduce energy consumption, making it ideal for lightweight, high-strength aerospace and automotive components. Fusion welding technologies are evolving through additive manufacturing integration and laser-based systems, enhancing precision and enabling complex geometries in metal fabrication. Both methods benefit from growing adoption of AI-driven process controls and sustainable practices, accelerating the shift towards Industry 4.0 in welding technology.

Solid-state joining

Friction welding, a solid-state joining process, produces strong, defect-free joints by generating heat through mechanical friction without melting, unlike fusion welding which involves melting and solidification of materials.

Heat-affected zone (HAZ)

Friction welding produces a smaller and more controlled heat-affected zone (HAZ) compared to fusion welding, resulting in less thermal distortion and improved mechanical properties in the welded joint.

Metallurgical bonding

Friction welding creates a superior metallurgical bond by generating solid-state diffusion without melting, while fusion welding relies on melting and solidification, often resulting in coarser microstructures and potential defects.

Interfacial temperature

Friction welding achieves lower interfacial temperatures by generating heat through mechanical friction, preventing melting and resulting in a solid-state bond, whereas fusion welding involves higher interfacial temperatures that melt the materials to form a joint.

Recrystallization

Friction welding promotes dynamic recrystallization through severe plastic deformation and localized heating, resulting in fine, equiaxed grains, whereas fusion welding involves melting and solidification processes that typically produce coarse, columnar grains due to nucleation and grain growth.

Thermomechanical processing

Friction welding utilizes severe thermomechanical deformation under solid-state conditions to join metals, minimizing thermal cycles and microstructural changes compared to fusion welding, which involves melting and solidification leading to extensive thermal gradients and grain growth.

Filler material

Friction welding eliminates the need for filler material by joining metals through heat generated from mechanical friction, whereas fusion welding requires filler material to melt and fuse the base metals together.

Forging pressure

Friction welding utilizes high forging pressure to generate heat through mechanical friction, producing strong solid-state joints without melting, while fusion welding relies on molten metal solidification with generally lower forging pressure.

Melting point

Friction welding joins metals by generating heat through mechanical friction without reaching the melting point, while fusion welding melts the base materials to create a joint.

Joint integrity

Friction welding provides superior joint integrity compared to fusion welding by producing a solid-state bond with minimal defects, reduced residual stresses, and enhanced mechanical properties.

Friction welding vs Fusion welding Infographic

njnir.com

njnir.com