Shape memory alloys exhibit unique properties such as the ability to return to their original shape after deformation due to phase transformation, making them ideal for applications requiring flexibility and adaptability. Superalloys, on the other hand, are designed for exceptional strength, corrosion resistance, and stability at high temperatures, commonly used in turbines and aerospace components. While shape memory alloys excel in responsive actuation, superalloys dominate in structural integrity under extreme mechanical and thermal stress.

Table of Comparison

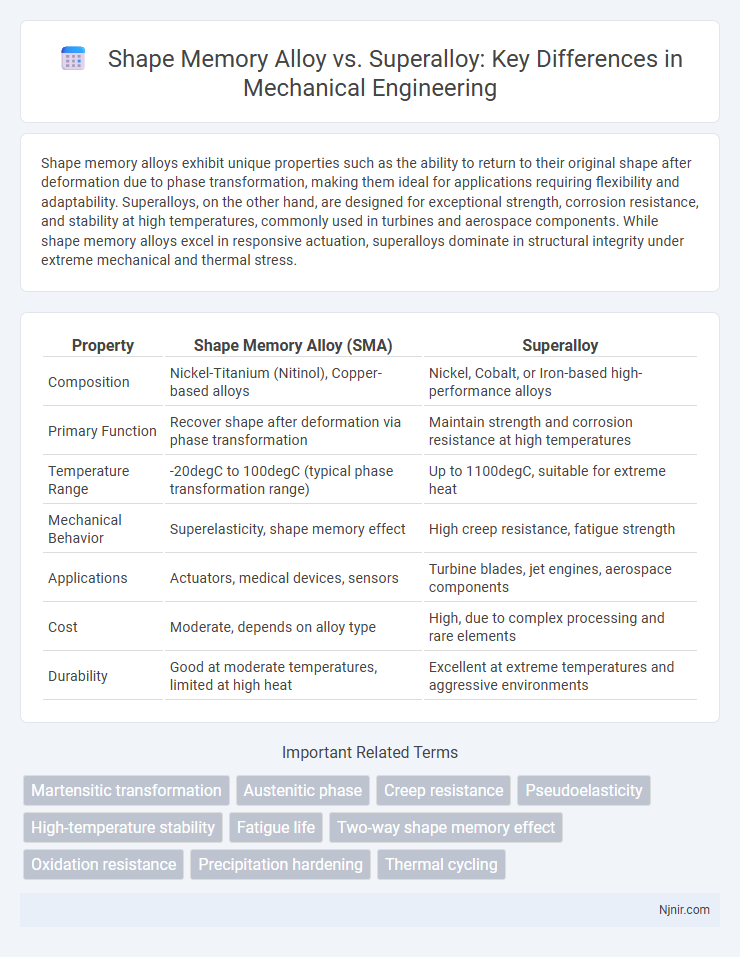

| Property | Shape Memory Alloy (SMA) | Superalloy |

|---|---|---|

| Composition | Nickel-Titanium (Nitinol), Copper-based alloys | Nickel, Cobalt, or Iron-based high-performance alloys |

| Primary Function | Recover shape after deformation via phase transformation | Maintain strength and corrosion resistance at high temperatures |

| Temperature Range | -20degC to 100degC (typical phase transformation range) | Up to 1100degC, suitable for extreme heat |

| Mechanical Behavior | Superelasticity, shape memory effect | High creep resistance, fatigue strength |

| Applications | Actuators, medical devices, sensors | Turbine blades, jet engines, aerospace components |

| Cost | Moderate, depends on alloy type | High, due to complex processing and rare elements |

| Durability | Good at moderate temperatures, limited at high heat | Excellent at extreme temperatures and aggressive environments |

Introduction to Shape Memory Alloys and Superalloys

Shape memory alloys (SMAs) are metallic materials characterized by their ability to return to a pre-defined shape when exposed to specific temperature changes, primarily composed of nickel-titanium (NiTi) or copper-aluminum-nickel alloys. Superalloys, typically based on nickel, cobalt, or iron, exhibit exceptional mechanical strength, resistance to thermal creep deformation, and corrosion resistance at high temperatures, making them ideal for aerospace and power generation applications. Both materials serve critical roles in advanced engineering, with SMAs enabling adaptive components through phase transformation and superalloys providing durability in extreme environments.

Fundamental Material Properties: Shape Memory Alloys vs Superalloys

Shape memory alloys (SMAs) exhibit unique phase transformation behavior that enables them to recover predefined shapes upon heating, driven by reversible martensitic transformations in materials like NiTi and Cu-based alloys. Superalloys, primarily based on nickel, cobalt, or iron, offer exceptional high-temperature strength, oxidation resistance, and creep resistance due to their complex microstructure with gamma prime (g') precipitates and solid-solution strengthening. While SMAs excel in elasticity and actuation with moderate strength, superalloys dominate in extreme thermal and mechanical environments, making each material suited for distinctly different engineering applications.

Composition and Microstructure Comparison

Shape memory alloys (SMAs) primarily consist of nickel-titanium (NiTi) or copper-based alloys, characterized by a unique martensitic-austenitic phase transformation enabling reversible deformation. Superalloys, mainly composed of nickel, cobalt, or iron with complex additions of chromium, aluminum, and titanium, exhibit a microstructure stabilized by g' and g'' precipitates enhancing high-temperature strength. While SMAs rely on a twinned martensitic microstructure for shape memory and superelasticity, superalloys possess a dendritic grain structure reinforcing creep resistance and oxidation stability in extreme environments.

Mechanical Performance and Fatigue Resistance

Shape memory alloys exhibit excellent mechanical performance through their unique ability to undergo large deformations and recover their original shape, providing superior strain recovery and energy absorption compared to conventional materials. Superalloys offer exceptional fatigue resistance and mechanical strength at high temperatures, maintaining structural integrity under cyclic loading conditions in extreme environments such as aerospace and power generation. The fatigue resistance of superalloys surpasses that of shape memory alloys, making superalloys preferred for applications requiring long-term durability under thermal and mechanical stress.

Thermal Stability and Operating Temperature Ranges

Shape memory alloys exhibit excellent thermal stability with operating temperature ranges typically between -100degC and 200degC, making them suitable for applications requiring moderate heat resistance and flexibility. Superalloys demonstrate superior thermal stability, maintaining mechanical strength and corrosion resistance at extreme temperatures up to 1100degC or higher, ideal for aerospace and turbine engine components. The high melting points and phase stability of superalloys enable efficient performance in harsh thermal environments where shape memory alloys would fail.

Corrosion and Oxidation Resistance

Shape memory alloys exhibit moderate corrosion resistance, often enhanced by surface treatments, but generally underperform compared to superalloys in harsh oxidative environments. Superalloys, composed primarily of nickel, cobalt, or iron with elements like chromium and aluminum, form stable oxide layers that provide exceptional corrosion and oxidation resistance at elevated temperatures. This makes superalloys ideal for applications in aerospace and power generation where prolonged exposure to corrosive gases and high heat is common.

Manufacturing Methods and Processability

Shape memory alloys (SMAs) are typically manufactured using processes like casting, powder metallurgy, and thermo-mechanical treatments that enable precise control over their phase transformation properties, while their processability often requires careful heat treatment to maintain shape memory effects. Superalloys are produced primarily through advanced casting methods, such as investment casting, and powder metallurgy technologies designed to enhance high-temperature strength and corrosion resistance, but their processability is challenged by their high hardness and potential for grain boundary cracking. Manufacturing SMAs demands intricate control of composition for reversible transformations, whereas superalloys require meticulous control of microstructure during forging and heat treatment to withstand extreme environments.

Applications in Mechanical Engineering Industries

Shape memory alloys (SMAs) excel in applications requiring adaptive components, such as actuators, vibration dampers, and temperature-sensitive couplings, due to their unique ability to return to a predefined shape after deformation. Superalloys are predominantly used in high-temperature environments like turbine blades, jet engines, and gas turbines, where exceptional strength, corrosion resistance, and thermal stability are critical. Mechanical engineering industries leverage SMAs for smart system integration and superalloys for structural components demanding durability under extreme mechanical and thermal stress.

Cost Considerations and Lifecycle Analysis

Shape memory alloys typically have higher initial material costs due to their complex manufacturing processes and rare element composition, whereas superalloys, though also expensive, benefit from established production methods and broader market availability. Lifecycle analysis reveals that shape memory alloys offer significant cost savings in maintenance and lifespan extension through their ability to recover deformation, reducing replacement frequency compared to superalloys that excel in high-temperature strength but may suffer from creep and fatigue over extended use. Selecting between these materials requires balancing upfront investment with long-term durability and operational efficiency, emphasizing total cost of ownership rather than material price alone.

Future Trends and Innovation in Advanced Alloys

Shape memory alloys (SMAs) are evolving with innovations in multiferroic coupling and enhanced fatigue resistance for biomedical and aerospace applications, while superalloys are advancing through additive manufacturing techniques and high-entropy alloy design to achieve superior temperature tolerance and creep resistance. Future trends highlight the integration of computational materials science and machine learning for tailored microstructure optimization in both alloy types. Research also focuses on developing environmentally friendly processing methods and recycling strategies to improve sustainability in advanced alloy production.

Martensitic transformation

Shape memory alloys exhibit reversible Martensitic transformation enabling shape recovery, whereas superalloys rely on phase stability and high-temperature strength without Martensitic transformation.

Austenitic phase

Austenitic phase in shape memory alloys exhibits reversible martensitic transformation enabling shape recovery, whereas in superalloys it provides high-temperature stability and corrosion resistance without transformational behavior.

Creep resistance

Superalloys exhibit superior creep resistance compared to shape memory alloys due to their enhanced high-temperature mechanical stability and microstructural strength.

Pseudoelasticity

Pseudoelasticity in shape memory alloys enables reversible strain recovery of up to 8%, contrasting with superalloys that lack this property and primarily rely on high-temperature strength and creep resistance.

High-temperature stability

Shape memory alloys exhibit limited high-temperature stability typically below 300degC, whereas superalloys maintain exceptional mechanical strength and corrosion resistance at temperatures exceeding 700degC.

Fatigue life

Shape memory alloys exhibit superior fatigue life due to their ability to undergo reversible phase transformations, whereas superalloys provide high-temperature strength but generally have lower fatigue resistance under cyclic loading.

Two-way shape memory effect

Two-way shape memory effect in shape memory alloys enables reversible deformation between two predefined shapes upon heating and cooling, unlike superalloys which primarily offer high-temperature strength and corrosion resistance without such reversible phase transformations.

Oxidation resistance

Shape memory alloys generally exhibit lower oxidation resistance compared to superalloys, which are specifically engineered with high-temperature oxidation-resistant coatings and alloying elements like chromium and aluminum to maintain structural integrity in extreme environments.

Precipitation hardening

Precipitation hardening in superalloys significantly enhances their high-temperature strength and creep resistance, whereas shape memory alloys primarily rely on phase transformation mechanisms rather than precipitation hardening for their unique mechanical properties.

Thermal cycling

Shape memory alloys exhibit exceptional thermal cycling durability due to their reversible phase transformations, whereas superalloys maintain structural integrity under high-temperature thermal cycling through their robust microstructural stability.

shape memory alloy vs superalloy Infographic

njnir.com

njnir.com