Centrifugal pumps utilize rotational kinetic energy to move fluids efficiently in high-flow, low-viscosity applications, whereas reciprocating pumps employ positive displacement mechanisms ideal for high-pressure, low-flow scenarios. Centrifugal pumps offer continuous flow with fewer pulsations, making them suitable for water supply and chemical processing. Reciprocating pumps deliver precise volumetric flow rates and can handle viscous fluids, making them essential for oil and gas or hydraulic systems.

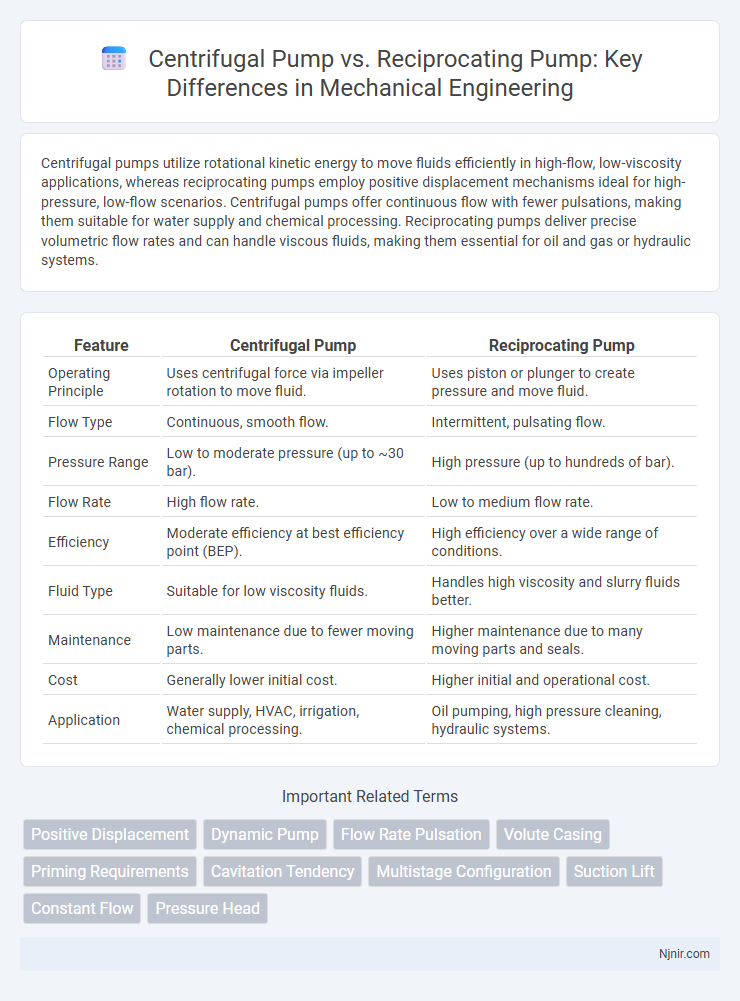

Table of Comparison

| Feature | Centrifugal Pump | Reciprocating Pump |

|---|---|---|

| Operating Principle | Uses centrifugal force via impeller rotation to move fluid. | Uses piston or plunger to create pressure and move fluid. |

| Flow Type | Continuous, smooth flow. | Intermittent, pulsating flow. |

| Pressure Range | Low to moderate pressure (up to ~30 bar). | High pressure (up to hundreds of bar). |

| Flow Rate | High flow rate. | Low to medium flow rate. |

| Efficiency | Moderate efficiency at best efficiency point (BEP). | High efficiency over a wide range of conditions. |

| Fluid Type | Suitable for low viscosity fluids. | Handles high viscosity and slurry fluids better. |

| Maintenance | Low maintenance due to fewer moving parts. | Higher maintenance due to many moving parts and seals. |

| Cost | Generally lower initial cost. | Higher initial and operational cost. |

| Application | Water supply, HVAC, irrigation, chemical processing. | Oil pumping, high pressure cleaning, hydraulic systems. |

Introduction to Centrifugal and Reciprocating Pumps

Centrifugal pumps utilize a rotating impeller to convert kinetic energy into fluid pressure, ideal for high flow rates and low viscosity liquids. Reciprocating pumps operate using a piston or diaphragm to create pressure through positive displacement, suitable for precise flow control and handling high-viscosity fluids. Both pump types are essential in industries such as water treatment, oil and gas, and chemical processing, with selection based on flow rate, pressure requirements, and fluid characteristics.

Working Principles: Centrifugal vs Reciprocating Pumps

Centrifugal pumps operate by converting rotational kinetic energy from an impeller into hydrodynamic energy, forcing fluid outward through centrifugal force. Reciprocating pumps use a piston or plunger moving back and forth within a cylinder, creating pressure changes that draw in and expel fluid in discrete volumes. The continuous flow of centrifugal pumps contrasts with the pulsating flow characteristic of reciprocating pumps, making their working principles fundamentally different in fluid movement and pressure generation.

Key Components and Construction Differences

Centrifugal pumps feature an impeller as the key component, housed within a casing designed to convert velocity into pressure, ideal for handling large flow rates with low viscosity fluids. Reciprocating pumps use pistons, plungers, or diaphragms within cylinders, driven by a crankshaft or cam mechanism, enabling precise flow control for high-pressure, low flow applications. The construction of centrifugal pumps emphasizes rotational motion and streamlined flow paths, while reciprocating pumps rely on linear motion and multiple valves to manage fluid intake and discharge.

Performance Characteristics and Efficiency

Centrifugal pumps deliver high flow rates with moderate pressure, exhibiting smooth and continuous output ideal for low-viscosity fluids but tend to have lower efficiency at high pressures. Reciprocating pumps provide high pressure with precise flow control, maintaining consistent efficiency across varying loads due to their positive displacement mechanism. Performance-wise, centrifugal pumps excel in applications requiring large volumes, while reciprocating pumps are favored for their superior efficiency and pressure in high-head, low-flow situations.

Flow Rate and Pressure Capabilities

Centrifugal pumps are designed for high flow rates, typically handling thousands of gallons per minute, with moderate pressure outputs usually below 400 psi. Reciprocating pumps generate significantly higher pressures, often exceeding 1,000 psi, but their flow rates are comparatively low, generally under a few hundred gallons per minute. The choice between these pumps depends on application requirements, with centrifugal pumps favoring volume and reciprocating pumps prioritizing pressure.

Applications and Suitable Industries

Centrifugal pumps are widely used in industries such as water treatment, agriculture, and chemical processing due to their efficiency in handling large volumes of low-viscosity fluids. Reciprocating pumps excel in applications requiring high pressure and precise flow control, making them ideal for oil and gas, hydraulic systems, and mining operations. Both pump types serve critical roles tailored to specific industrial demands, with centrifugal pumps favored for continuous flow and reciprocating pumps preferred for metering and high-pressure tasks.

Maintenance Requirements and Reliability

Centrifugal pumps typically require less maintenance due to fewer moving parts and a simpler design, resulting in higher reliability for continuous operation in applications like water supply and HVAC systems. Reciprocating pumps demand more frequent maintenance because of their complex components such as valves and pistons, but they offer superior reliability in handling high-pressure, low-flow applications like chemical injection and oil metering. Selecting between these pump types depends on balancing maintenance capabilities with operational requirements to maximize system performance and uptime.

Energy Consumption and Operational Costs

Centrifugal pumps generally consume less energy due to their continuous flow design and lower power requirements, making them more cost-effective for high-volume, low-pressure applications. Reciprocating pumps, with their positive displacement mechanism, tend to use more energy and incur higher operational costs because of increased maintenance needs and wear from pulsating flow. Energy consumption and maintenance frequency are critical factors influencing the higher total cost of ownership for reciprocating pumps compared to centrifugal pumps in industrial settings.

Advantages and Disadvantages Compared

Centrifugal pumps offer advantages such as simple design, smooth flow, and suitability for high flow rates with low viscosity fluids, but they exhibit lower efficiency at high pressure and struggle with viscous liquids. Reciprocating pumps provide high pressure output, excellent efficiency for viscous fluids, and precise flow control, yet they have complex construction, higher maintenance needs, and pulsating flow patterns. Choosing between centrifugal and reciprocating pumps depends on application requirements like flow rate, fluid viscosity, pressure, and maintenance capabilities.

Selection Criteria for Industrial Use

Centrifugal pumps excel in applications requiring high flow rates and low to medium pressure, making them ideal for water supply, chemical processing, and HVAC systems. Reciprocating pumps provide precise flow control and high pressure capabilities suited for metering, oil injection, and hydraulic systems. Selection criteria focus on fluid viscosity, required pressure, flow stability, maintenance frequency, and energy efficiency to ensure optimal industrial performance.

Positive Displacement

Reciprocating pumps, as positive displacement devices, deliver a fixed volume of fluid per cycle, providing precise flow rates and high pressure, unlike centrifugal pumps that rely on kinetic energy and vary flow with system resistance.

Dynamic Pump

Dynamic pumps, such as centrifugal pumps, provide continuous flow through rotational energy, making them ideal for high-flow, low-pressure applications compared to reciprocating pumps, which deliver pulsating flow suitable for high-pressure, low-flow scenarios.

Flow Rate Pulsation

Centrifugal pumps deliver a smooth, continuous flow with minimal pulsation, while reciprocating pumps generate high flow rate pulsations due to their piston-driven operation.

Volute Casing

The volute casing in centrifugal pumps efficiently converts velocity to pressure by gradually expanding the flow area, whereas reciprocating pumps typically lack volute casings as they rely on positive displacement rather than kinetic energy conversion.

Priming Requirements

Centrifugal pumps require priming to remove air and create suction, while reciprocating pumps are generally self-priming due to their positive displacement mechanism.

Cavitation Tendency

Centrifugal pumps exhibit a higher cavitation tendency at low flow rates due to reduced pressure at the impeller eye, whereas reciprocating pumps generally have lower cavitation risk because of their positive displacement mechanism maintaining consistent suction pressure.

Multistage Configuration

Multistage centrifugal pumps use multiple impellers to achieve higher pressure in a single pump, whereas reciprocating pumps increase pressure through multiple cylinders operating in a sequence.

Suction Lift

Centrifugal pumps generally have a lower suction lift, typically up to 7 meters, whereas reciprocating pumps can achieve higher suction lifts beyond 7 meters due to their positive displacement mechanism.

Constant Flow

Centrifugal pumps provide a continuous, constant flow ideal for low-viscosity fluids, whereas reciprocating pumps deliver pulsating flow with high pressure suitable for precise volume control in high-viscosity or variable flow applications.

Pressure Head

Centrifugal pumps generate lower pressure head suitable for high-flow, low-pressure applications, while reciprocating pumps produce higher pressure head ideal for low-flow, high-pressure systems.

centrifugal pump vs reciprocating pump Infographic

njnir.com

njnir.com