Permanent magnet motors offer higher efficiency and power density compared to induction motors, making them ideal for applications requiring compact size and energy savings. Induction motors, however, are typically more robust, cost-effective, and simpler to maintain, suitable for heavy-duty industrial environments. The choice between these motor types depends on balancing performance demands with cost and operational conditions.

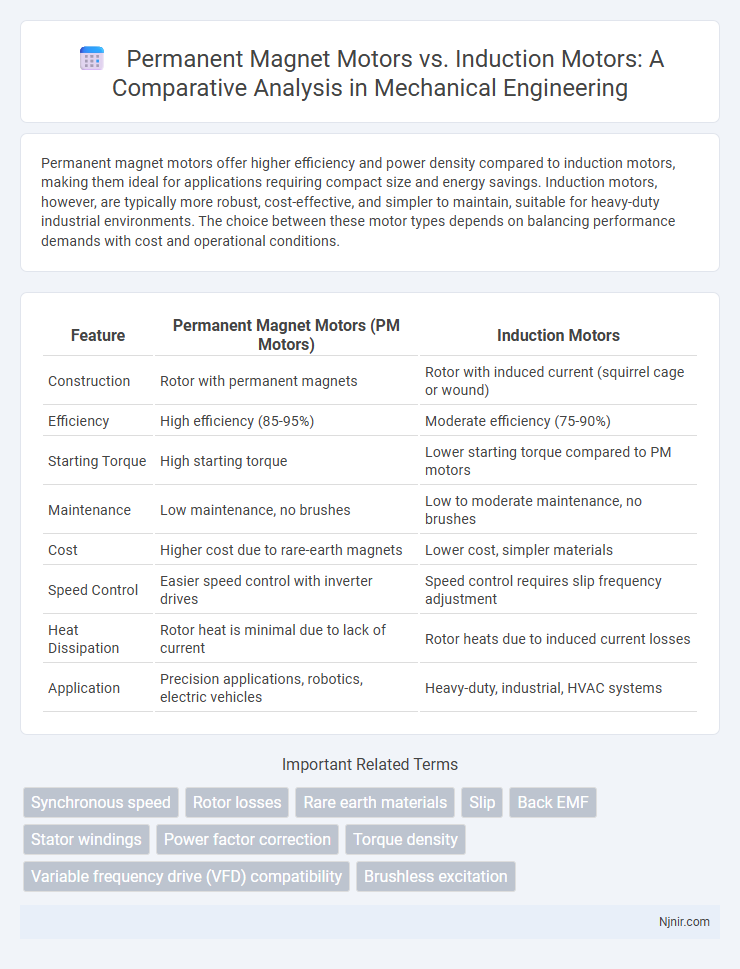

Table of Comparison

| Feature | Permanent Magnet Motors (PM Motors) | Induction Motors |

|---|---|---|

| Construction | Rotor with permanent magnets | Rotor with induced current (squirrel cage or wound) |

| Efficiency | High efficiency (85-95%) | Moderate efficiency (75-90%) |

| Starting Torque | High starting torque | Lower starting torque compared to PM motors |

| Maintenance | Low maintenance, no brushes | Low to moderate maintenance, no brushes |

| Cost | Higher cost due to rare-earth magnets | Lower cost, simpler materials |

| Speed Control | Easier speed control with inverter drives | Speed control requires slip frequency adjustment |

| Heat Dissipation | Rotor heat is minimal due to lack of current | Rotor heats due to induced current losses |

| Application | Precision applications, robotics, electric vehicles | Heavy-duty, industrial, HVAC systems |

Introduction to Motor Types in Mechanical Engineering

Permanent magnet motors use magnets embedded in the rotor to create a constant magnetic field, offering high efficiency and torque density, ideal for compact and precise mechanical engineering applications. Induction motors operate by inducing current in the rotor through electromagnetic induction, known for robustness, simplicity, and cost-effectiveness in heavy-duty industrial machinery. Understanding these motor types is crucial in mechanical engineering to select the optimal motor based on performance, efficiency, and application requirements.

Fundamental Principles of Permanent Magnet Motors

Permanent magnet motors operate based on the interaction between the magnetic field generated by permanent magnets on the rotor and the electromagnetic field produced by the stator windings, eliminating the need for external excitation. These motors utilize rare-earth magnets, such as neodymium or samarium-cobalt, to create a constant magnetic flux, enhancing efficiency and torque density compared to induction motors. The absence of rotor current reduces copper losses and heat generation, enabling higher performance and reliability in applications demanding precise speed control and compact design.

Key Characteristics of Induction Motors

Induction motors feature a robust, squirrel-cage rotor design that ensures durability and low maintenance requirements in industrial applications. They operate on electromagnetic induction between the stator and rotor, providing reliable torque and efficiency across a wide range of speeds and loads. These motors are widely favored for their cost-effectiveness, simplicity, and ability to handle harsh environments without permanent magnets.

Efficiency Comparison: Permanent Magnet vs Induction Motors

Permanent magnet motors typically offer higher efficiency across various load conditions compared to induction motors due to reduced rotor losses and improved power density. Induction motors experience greater energy losses from slip-induced rotor currents, leading to lower overall efficiency especially at partial loads. Advances in rare-earth magnet technology further enhance the performance and efficiency of permanent magnet motors in industrial and automotive applications.

Performance and Torque Characteristics

Permanent magnet motors deliver higher torque density and superior efficiency due to their strong magnetic fields generated by rare-earth magnets, resulting in excellent performance at low speeds. Induction motors provide robust durability and cost-effectiveness but produce lower starting torque and reduced efficiency under varying load conditions. The torque-speed curve of permanent magnet motors remains relatively flat, offering consistent torque across a broad speed range, whereas induction motors exhibit a torque drop-off at higher speeds.

Control Methods and Drive Requirements

Permanent magnet motors offer precise control through vector control and field-oriented control (FOC), enabling higher efficiency and dynamic performance with simpler drive electronics due to the absence of rotor currents. Induction motors require more complex drive systems employing scalar control or advanced sensorless vector control to estimate rotor flux, resulting in higher computational demands and typically lower efficiency under variable speed conditions. Drive requirements for permanent magnet motors often include careful torque and flux management to prevent demagnetization, while induction motors emphasize rotor resistance estimation and slip control for stable operation.

Cost Analysis and Lifecycle Considerations

Permanent magnet motors typically have higher upfront costs due to expensive rare-earth materials but offer greater energy efficiency, leading to lower operational expenses over their lifespan. Induction motors are less costly initially and more widely available but may incur higher maintenance and energy costs due to lower efficiency and brush or rotor wear. Lifecycle cost analysis often favors permanent magnet motors in applications requiring continuous operation and energy savings, while induction motors may be preferable for short-term, cost-sensitive deployments.

Maintenance and Reliability Factors

Permanent magnet motors require less maintenance due to the absence of brushes and slip rings, reducing wear and the need for frequent servicing. Induction motors, with their simpler construction, often have reliable performance but demand regular checks on bearings and rotor conditions to prevent failures. The higher efficiency and lower thermal stress in permanent magnet motors contribute to enhanced reliability and longer operational life compared to induction motors.

Application Suitability in Mechanical Systems

Permanent magnet motors offer superior efficiency and high torque density, making them ideal for precision applications such as robotics, aerospace, and electric vehicles where compact size and energy savings are critical. Induction motors excel in ruggedness and cost-effectiveness, suitable for industrial machinery, pumps, and HVAC systems requiring reliable operation under variable loads and harsh environments. The choice between the two depends on factors like required torque-to-weight ratio, efficiency demands, maintenance constraints, and initial investment in specific mechanical system applications.

Future Trends in Motor Technology

Permanent magnet motors are gaining prominence due to higher efficiency, compact size, and superior power density compared to traditional induction motors. Advances in rare-earth magnet materials enhance torque performance while reducing weight, supporting electric vehicle and renewable energy applications. Innovations in sensorless control and thermal management further optimize permanent magnet motor reliability and longevity, shaping future motor technology trends.

Synchronous speed

Permanent magnet motors maintain synchronous speed precisely due to their rotor magnets, while induction motors operate slightly below synchronous speed because of slip.

Rotor losses

Permanent magnet motors significantly reduce rotor losses compared to induction motors due to the absence of induced currents in the rotor.

Rare earth materials

Permanent magnet motors use rare earth materials like neodymium and dysprosium for high magnetic strength and efficiency, while induction motors avoid these costly rare earth elements by relying on electromagnetic induction.

Slip

Permanent magnet motors operate with near-zero slip due to their synchronous speed, while induction motors exhibit slip ranging from 1% to 6% under load to generate torque.

Back EMF

Permanent magnet motors generate higher and more consistent Back EMF than induction motors, resulting in improved efficiency and better speed control performance.

Stator windings

Permanent magnet motors feature simplified stator windings with lower resistance and reduced copper losses compared to the complex, multi-layered stator windings found in induction motors.

Power factor correction

Permanent magnet motors offer superior power factor correction compared to induction motors due to their inherent ability to maintain near-unity power factor under varying loads.

Torque density

Permanent magnet motors exhibit higher torque density compared to induction motors due to their efficient magnetic flux generation and reduced energy losses.

Variable frequency drive (VFD) compatibility

Permanent magnet motors exhibit higher efficiency and better torque control when paired with variable frequency drives (VFDs) compared to induction motors, which may experience reduced efficiency and increased heat generation under VFD operation.

Brushless excitation

Permanent magnet motors feature brushless excitation through embedded magnets in the rotor, providing higher efficiency and torque density compared to induction motors that rely on electromagnetic induction for rotor excitation.

Permanent magnet motors vs induction motors Infographic

njnir.com

njnir.com