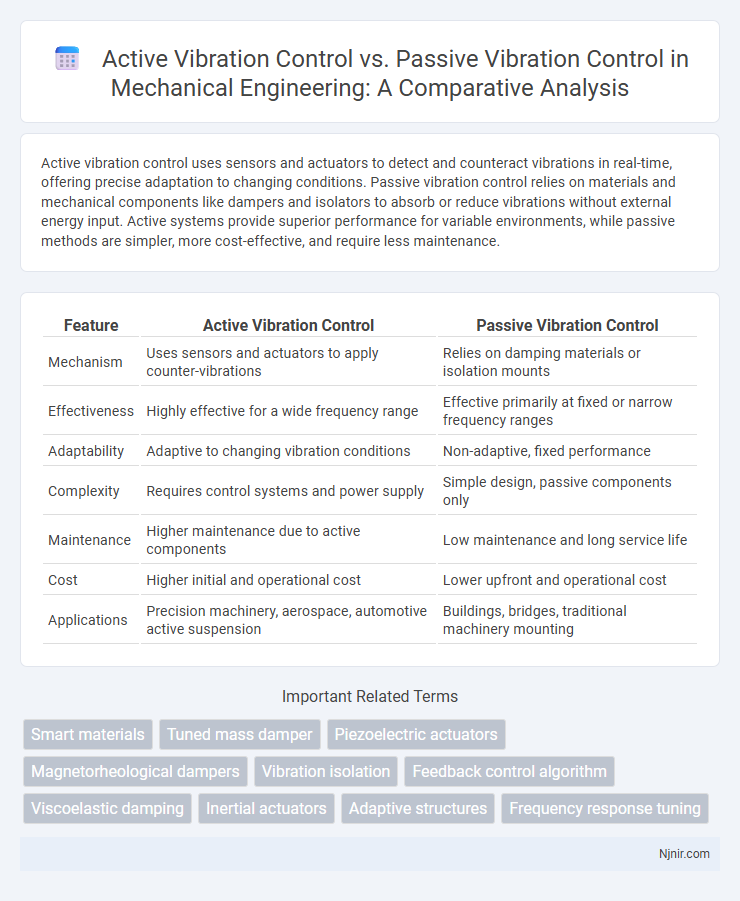

Active vibration control uses sensors and actuators to detect and counteract vibrations in real-time, offering precise adaptation to changing conditions. Passive vibration control relies on materials and mechanical components like dampers and isolators to absorb or reduce vibrations without external energy input. Active systems provide superior performance for variable environments, while passive methods are simpler, more cost-effective, and require less maintenance.

Table of Comparison

| Feature | Active Vibration Control | Passive Vibration Control |

|---|---|---|

| Mechanism | Uses sensors and actuators to apply counter-vibrations | Relies on damping materials or isolation mounts |

| Effectiveness | Highly effective for a wide frequency range | Effective primarily at fixed or narrow frequency ranges |

| Adaptability | Adaptive to changing vibration conditions | Non-adaptive, fixed performance |

| Complexity | Requires control systems and power supply | Simple design, passive components only |

| Maintenance | Higher maintenance due to active components | Low maintenance and long service life |

| Cost | Higher initial and operational cost | Lower upfront and operational cost |

| Applications | Precision machinery, aerospace, automotive active suspension | Buildings, bridges, traditional machinery mounting |

Introduction to Vibration Control in Mechanical Engineering

Active vibration control in mechanical engineering utilizes sensors, actuators, and control algorithms to dynamically reduce or eliminate unwanted vibrations in systems, offering adaptive and real-time response capabilities. Passive vibration control relies on materials, dampers, and isolators to absorb or dissipate vibrational energy without external power, providing simplicity and reliability in applications with stable vibration patterns. Understanding the distinctions between active and passive methods enables engineers to select appropriate vibration mitigation strategies based on system complexity, frequency range, and environmental conditions.

Fundamentals of Vibration Control Systems

Active vibration control systems utilize sensors, actuators, and control algorithms to detect and counteract vibrations in real-time, providing adaptive and precise attenuation across varying frequencies. Passive vibration control relies on materials and mechanical elements such as dampers, isolators, and absorbers to dissipate or block vibrational energy without external energy input. Fundamental differences include active systems' ability to respond dynamically to changing conditions versus passive systems' fixed properties and simpler implementation.

Overview of Passive Vibration Control Techniques

Passive vibration control techniques utilize materials and structural modifications such as dampers, isolators, and tuned mass dampers to reduce unwanted vibrations without requiring external energy input. These methods rely on inherent material properties like damping, stiffness, and mass distribution to absorb and dissipate vibrational energy. Common applications include rubber mounts for machinery isolation, viscoelastic layers in composite structures, and base isolation systems in buildings to enhance structural stability and comfort.

Principles of Active Vibration Control Methods

Active vibration control utilizes sensors and actuators to continuously monitor and counteract unwanted vibrations by generating opposing forces based on real-time feedback signals. Control algorithms, such as adaptive or optimal control, process sensor data to adjust actuator responses dynamically, enhancing vibration suppression efficiency in various mechanical systems. This method contrasts with passive vibration control, which relies on materials or structural elements to dissipate energy without active input or adaptability.

Comparison Between Active and Passive Vibration Control

Active vibration control utilizes sensors and actuators to detect and counteract vibrations in real-time, offering adaptive and precise suppression across a wide frequency range. Passive vibration control relies on materials and mechanical elements like dampers and isolators to absorb or dissipate energy, providing simplicity and reliability without external power. Compared to passive systems, active control achieves superior effectiveness in dynamic environments but requires higher complexity and energy consumption.

Performance Metrics in Vibration Suppression

Active vibration control systems achieve superior performance metrics in vibration suppression by dynamically adjusting control forces in real-time, resulting in higher damping ratios and broader frequency range attenuation compared to passive methods. Passive vibration control relies on fixed mechanical properties like mass, stiffness, and damping materials, which limit effectiveness to specific frequency bands and often yield lower vibration reduction levels. Quantitatively, active systems can reduce vibration amplitudes by up to 80%, whereas passive solutions typically achieve around 40-60% reduction, highlighting the advantage of active control in precision and adaptability.

Applications in Automotive and Aerospace Engineering

Active vibration control employs sensors and actuators to dynamically reduce vibrations, enhancing ride comfort and structural integrity in automotive and aerospace engineering. Passive vibration control utilizes materials like dampers and isolators to absorb and dissipate energy, providing cost-effective and maintenance-free solutions for noise reduction and stability. In aerospace, active systems optimize flight performance and fatigue life, while passive methods are favored for their simplicity and reliability in routine vehicle operations.

Cost and Maintenance Considerations

Active vibration control systems typically involve higher initial investment and operational costs due to sensors, actuators, and control algorithms, but offer real-time adaptability reducing long-term maintenance needs. Passive vibration control relies on simpler, often cheaper materials like dampers and isolation mounts, resulting in lower upfront costs but potentially higher maintenance and replacement expenses over time. Evaluating cost-effectiveness depends on application requirements, frequency of vibration, and acceptable upkeep intervals.

Recent Advances in Vibration Control Technologies

Recent advances in vibration control technologies highlight significant improvements in active vibration control systems, utilizing adaptive algorithms and real-time feedback sensors to enhance precision and responsiveness in various applications. Passive vibration control methods continue to evolve with the development of advanced materials such as viscoelastic dampers and meta-materials that offer superior energy dissipation without requiring external power. Integration of smart materials like piezoelectric sensors and actuators in hybrid control systems marks a pivotal advancement, combining the reliability of passive techniques with the efficiency of active control for optimal vibration mitigation.

Future Trends in Active and Passive Vibration Control

Future trends in active vibration control emphasize advanced smart materials, adaptive algorithms, and real-time sensory feedback to enhance precision and energy efficiency in diverse applications such as aerospace and automotive industries. Passive vibration control is evolving through the integration of novel composite materials and metamaterials, enabling lightweight, cost-effective solutions with improved damping capabilities. Hybrid systems combining active and passive techniques are gaining traction, offering optimized performance by leveraging the strengths of both approaches in dynamic environments.

Smart materials

Active vibration control using smart materials like piezoelectric sensors outperforms passive vibration control by dynamically adapting to changing conditions for enhanced precision and efficiency.

Tuned mass damper

Tuned mass dampers in active vibration control systems dynamically adjust to counteract structural oscillations, offering superior performance and adaptability compared to passive vibration control systems that rely on fixed, unchanging mass-spring elements.

Piezoelectric actuators

Active vibration control using piezoelectric actuators provides precise real-time damping of structural vibrations by converting electrical signals into mechanical strain, unlike passive vibration control which relies on fixed material properties without adaptive response.

Magnetorheological dampers

Magnetorheological dampers enable active vibration control by dynamically adjusting fluid viscosity through magnetic fields, offering superior real-time adaptability and performance compared to traditional passive vibration control systems.

Vibration isolation

Active vibration control uses real-time sensors and actuators to cancel vibrations, providing superior vibration isolation compared to passive vibration control, which relies on fixed dampers and isolators to absorb and reduce vibration transmission.

Feedback control algorithm

Active vibration control utilizes feedback control algorithms such as PID, adaptive, and model predictive control to dynamically counteract vibrations, offering superior precision compared to passive vibration control systems that rely on fixed mechanical components for dampening.

Viscoelastic damping

Viscoelastic damping in active vibration control provides adaptive energy dissipation through real-time stiffness modulation, whereas passive vibration control relies on fixed material properties offering consistent but less flexible damping performance.

Inertial actuators

Inertial actuators enhance active vibration control by dynamically counteracting vibrations using feedback mechanisms, unlike passive vibration control which relies on fixed dampers and isolators without adaptive response.

Adaptive structures

Adaptive structures using active vibration control employ real-time sensing and actuators to dynamically reduce vibrations, offering superior performance and customization compared to passive vibration control systems that rely on fixed damping materials.

Frequency response tuning

Active vibration control achieves precise frequency response tuning through real-time feedback and adaptive algorithms, whereas passive vibration control relies on fixed-material properties and damping elements, limiting its ability to adjust to varying frequencies.

Active vibration control vs passive vibration control Infographic

njnir.com

njnir.com