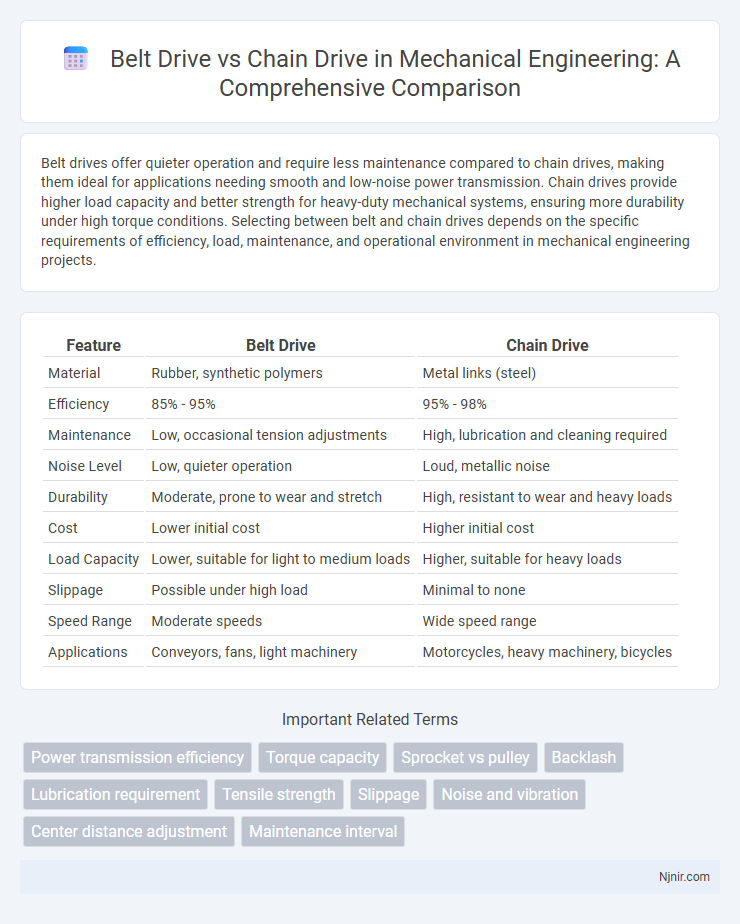

Belt drives offer quieter operation and require less maintenance compared to chain drives, making them ideal for applications needing smooth and low-noise power transmission. Chain drives provide higher load capacity and better strength for heavy-duty mechanical systems, ensuring more durability under high torque conditions. Selecting between belt and chain drives depends on the specific requirements of efficiency, load, maintenance, and operational environment in mechanical engineering projects.

Table of Comparison

| Feature | Belt Drive | Chain Drive |

|---|---|---|

| Material | Rubber, synthetic polymers | Metal links (steel) |

| Efficiency | 85% - 95% | 95% - 98% |

| Maintenance | Low, occasional tension adjustments | High, lubrication and cleaning required |

| Noise Level | Low, quieter operation | Loud, metallic noise |

| Durability | Moderate, prone to wear and stretch | High, resistant to wear and heavy loads |

| Cost | Lower initial cost | Higher initial cost |

| Load Capacity | Lower, suitable for light to medium loads | Higher, suitable for heavy loads |

| Slippage | Possible under high load | Minimal to none |

| Speed Range | Moderate speeds | Wide speed range |

| Applications | Conveyors, fans, light machinery | Motorcycles, heavy machinery, bicycles |

Overview of Belt Drive and Chain Drive Systems

Belt drive systems use flexible belts typically made of rubber or synthetic materials to transmit power between pulleys, offering smooth and quiet operation with low maintenance requirements. Chain drive systems employ metal chains and sprockets, providing high torque transmission and durability suitable for heavy-duty applications but requiring regular lubrication and tension adjustments. Both systems have distinct advantages in efficiency and application depending on load, speed, and environmental conditions.

Fundamental Working Principles

Belt drives operate by transferring power through a flexible belt tensioned between pulleys, relying on friction to transmit motion smoothly and quietly. Chain drives use interlocking metal links engaged with sprockets to transfer torque mechanically, providing higher load capacity and positive engagement without slippage. The fundamental difference lies in belt drives' reliance on friction and elasticity versus chain drives' direct mechanical interlock for power transmission.

Key Components and Materials Used

Belt drive systems primarily consist of belts made from reinforced rubber or polyurethane and pulleys often constructed from aluminum or steel, ensuring flexibility and quiet operation. Chain drives use metal chains, typically steel alloys, and sprockets made from hardened steel to withstand higher torque and provide durability. The choice of materials directly impacts the efficiency, maintenance needs, and lifespan of the drive system.

Efficiency Comparison

Belt drives typically offer efficiency rates of 90-98%, reflecting lower friction and quieter operation compared to chain drives, which average 85-95% efficiency due to metal-on-metal contact and higher maintenance needs. The efficiency of chain drives can degrade with wear, stretching, and insufficient lubrication, impacting power transmission reliability. Optimal system design often favors belt drives for applications prioritizing energy conservation and reduced mechanical losses.

Power Transmission Capacity

Chain drives typically offer higher power transmission capacity than belt drives, making them suitable for heavy-duty applications with significant torque requirements. Belt drives excel in quieter operation and require less maintenance but may slip under high loads, limiting their use in high-torque scenarios. Advanced synchronous belts can narrow the performance gap, yet chains remain the preferred choice for maximum power transfer efficiency and durability.

Maintenance Requirements

Belt drives require less frequent maintenance compared to chain drives due to their enclosed design and resistance to dirt and debris. Chain drives demand regular lubrication, tension adjustments, and cleaning to prevent wear and ensure smooth operation. Proper maintenance of chain drives extends their lifespan but involves more time and effort than the relatively low-maintenance belt systems.

Noise and Vibration Factors

Belt drive systems produce significantly less noise and vibration compared to chain drives due to the flexible nature of belts and the absence of metal-to-metal contact. Chain drives generate more noise from the engagement of metal links and sprockets, leading to higher vibration levels that may require additional damping components. Reduced noise and vibration in belt drives contribute to smoother operation and lower maintenance requirements in various mechanical applications.

Durability and Lifespan

Belt drives typically offer greater durability and longer lifespan compared to chain drives due to their resistance to corrosion, reduced friction, and lack of lubrication requirements. Chain drives, while robust and capable of transmitting higher torque, tend to wear faster because of metal-on-metal contact and require regular maintenance to prevent rust and elongation. High-quality synchronous belts made from reinforced rubber compounds can last up to 100,000 miles, whereas standard chains often need replacement after 20,000 to 30,000 miles under similar conditions.

Cost and Installation Considerations

Belt drives generally offer lower initial costs and simpler installation processes compared to chain drives due to fewer components and reduced maintenance requirements. Chain drives may involve higher upfront expenses and more complex installation, especially with tensioning and alignment needs, but they provide durability in heavy-duty applications. Cost-effectiveness of belt drives is influenced by material lifespan, while chain drives often require investment in lubrication and periodic adjustments.

Applications in Mechanical Engineering

Belt drives are commonly used in mechanical engineering applications requiring smooth, quiet operation and moderate power transmission, such as in HVAC systems, conveyor belts, and light machinery. Chain drives excel in heavy-duty applications demanding high torque and durability, including motorcycles, bicycles, and industrial machinery with precise synchronization needs. The choice between belt and chain drives depends on factors like load requirements, maintenance preferences, operational environment, and the need for efficiency or flexibility.

Power transmission efficiency

Belt drives typically offer lower power transmission efficiency around 90-98% compared to chain drives, which achieve higher efficiency levels of 95-99% due to reduced slippage and better mechanical engagement.

Torque capacity

Belt drives typically offer lower torque capacity but require less maintenance and provide quieter operation compared to chain drives, which can handle higher torque loads and are more suitable for heavy-duty applications.

Sprocket vs pulley

Sprockets in chain drives offer precise engagement and higher load capacity for heavy-duty power transmission, while pulleys in belt drives provide quieter operation and require less maintenance but may experience slippage under high torque.

Backlash

Belt drives provide minimal backlash compared to chain drives, resulting in smoother and more precise power transmission in mechanical systems.

Lubrication requirement

Belt drives require minimal to no lubrication compared to chain drives, which need regular lubrication to prevent wear and ensure smooth operation.

Tensile strength

Belt drives typically exhibit lower tensile strength compared to chain drives, making chain drives more suitable for high-torque applications requiring greater durability and load capacity.

Slippage

Belt drives experience less slippage than chain drives due to their higher friction coefficient and continuous contact surface.

Noise and vibration

Belt drives produce significantly less noise and vibration compared to chain drives, making them ideal for quieter and smoother operation in mechanical systems.

Center distance adjustment

Belt drives offer easier and more precise center distance adjustment compared to chain drives, which require more complex tensioning mechanisms.

Maintenance interval

Belt drives require maintenance intervals of up to 100,000 miles due to low wear, while chain drives typically need lubrication and adjustment every 500 to 1,000 miles for optimal performance.

Belt drive vs chain drive Infographic

njnir.com

njnir.com