Fatigue in mechanical engineering refers to the progressive structural damage that occurs when a material undergoes cyclic loading, resulting in crack initiation and growth over time. Fracture denotes the sudden and complete separation of a material once the crack reaches a critical size, often leading to catastrophic failure. Understanding the distinction between fatigue and fracture is essential for designing durable components that can withstand repeated stress without unexpected breakage.

Table of Comparison

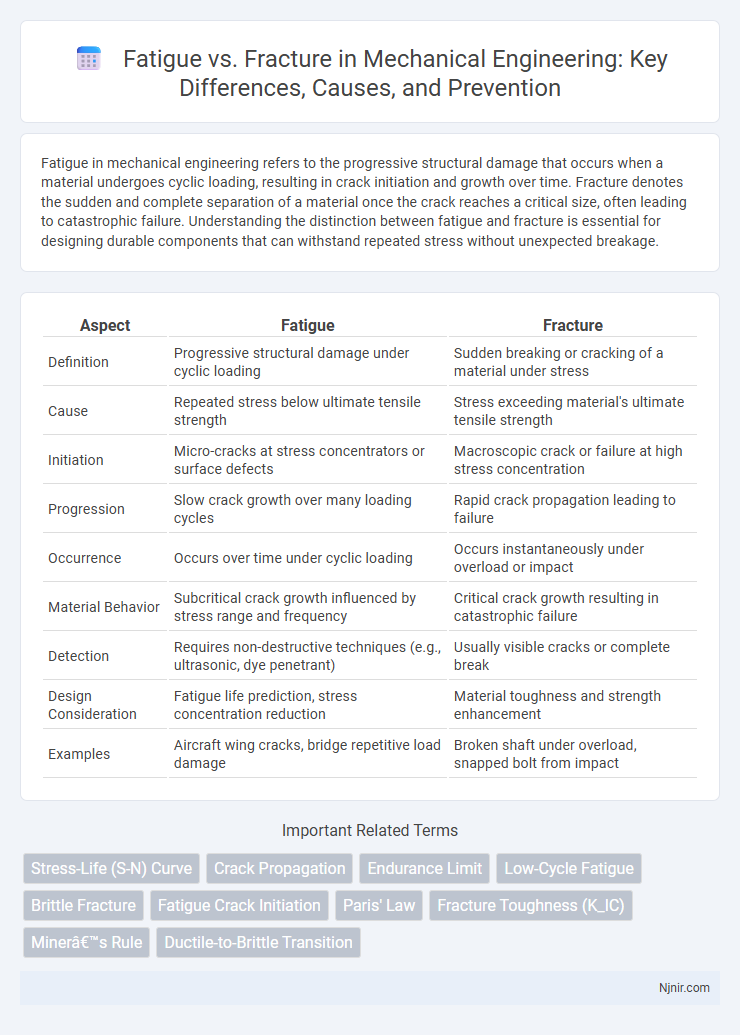

| Aspect | Fatigue | Fracture |

|---|---|---|

| Definition | Progressive structural damage under cyclic loading | Sudden breaking or cracking of a material under stress |

| Cause | Repeated stress below ultimate tensile strength | Stress exceeding material's ultimate tensile strength |

| Initiation | Micro-cracks at stress concentrators or surface defects | Macroscopic crack or failure at high stress concentration |

| Progression | Slow crack growth over many loading cycles | Rapid crack propagation leading to failure |

| Occurrence | Occurs over time under cyclic loading | Occurs instantaneously under overload or impact |

| Material Behavior | Subcritical crack growth influenced by stress range and frequency | Critical crack growth resulting in catastrophic failure |

| Detection | Requires non-destructive techniques (e.g., ultrasonic, dye penetrant) | Usually visible cracks or complete break |

| Design Consideration | Fatigue life prediction, stress concentration reduction | Material toughness and strength enhancement |

| Examples | Aircraft wing cracks, bridge repetitive load damage | Broken shaft under overload, snapped bolt from impact |

Understanding Fatigue and Fracture in Mechanical Engineering

Fatigue in mechanical engineering refers to the progressive and localized structural damage that occurs when a material is subjected to cyclic loading, leading to crack initiation and growth over time. Fracture, on the other hand, is the sudden and complete separation of a material into pieces under stress, often following crack propagation caused by fatigue or other mechanisms. Understanding the distinction between fatigue and fracture is crucial for predicting component lifespan, designing against failure, and enhancing material durability in engineering applications.

Fundamental Differences Between Fatigue and Fracture

Fatigue is a progressive and localized structural damage that occurs when a material is subjected to cyclic loading, whereas fracture is the rapid propagation of a crack leading to complete separation of the material. Fatigue failure develops over time due to repeated stress below the material's ultimate tensile strength, while fracture typically results from a single overload or sudden impact exceeding the material's fracture toughness. Fundamental differences include the initiation and growth of microcracks in fatigue versus the immediate brittle or ductile crack propagation seen in fracture.

Causes and Mechanisms of Fatigue Failure

Fatigue failure occurs due to repetitive cyclic loading that induces microscopic cracks, which propagate over time even under stresses lower than the material's tensile strength. Causes of fatigue include fluctuating stress concentrations, material defects, and environmental factors such as corrosion that accelerate crack initiation. The mechanism involves crack nucleation at stress risers, crack propagation through cyclic plastic deformation, and eventual fracture when the remaining cross-section can no longer support the applied load.

Fracture Types: Ductile vs. Brittle

Fracture types are classified primarily as ductile or brittle, each exhibiting distinct mechanical behaviors and failure characteristics. Ductile fractures involve significant plastic deformation before failure, often displaying a fibrous or cup-and-cone appearance due to microvoid coalescence, while brittle fractures occur suddenly with minimal plastic deformation, characterized by a shiny, granular surface. Understanding the differences between ductile and brittle fractures is critical in engineering applications to predict material performance under cyclic loading and prevent fatigue failure.

Microstructural Behavior Under Cyclic Loading

Fatigue and fracture under cyclic loading are governed by distinct microstructural mechanisms where fatigue involves the initiation and propagation of cracks due to repeated stress, often at grain boundaries or inclusions. Microstructural features like dislocation movement, accumulation of slip bands, and microvoid coalescence play critical roles in fatigue crack initiation and growth. In contrast, fracture typically results from a single overload event causing rapid crack propagation, with microstructural toughness and grain size significantly influencing resistance to crack spreading.

Influence of Material Properties on Fatigue and Fracture

Material properties such as hardness, toughness, and grain structure critically influence fatigue and fracture behavior by dictating crack initiation and propagation rates. High toughness materials resist crack growth under cyclic loading, enhancing fatigue life, while brittle materials with low fracture toughness are more prone to sudden fracture even under lower stress levels. Optimizing microstructure through heat treatment or alloying improves resistance to both fatigue and fracture.

Methods for Detecting Fatigue and Fracture

Non-destructive testing (NDT) methods such as ultrasonic testing, magnetic particle inspection, and acoustic emission are widely used to detect early signs of fatigue and fracture in materials. Advanced imaging techniques like scanning electron microscopy (SEM) provide detailed analysis of crack initiation and propagation at microstructural levels. Strain gauge measurements and fracture mechanics-based modeling also play crucial roles in assessing fatigue life and predicting fracture behavior in engineering components.

Fatigue Life Prediction and Assessment Techniques

Fatigue life prediction relies on advanced methods such as S-N curves, fracture mechanics, and strain-life approaches to accurately estimate the number of cycles a material can endure before failure. Assessment techniques integrate nondestructive testing, damage tolerance analysis, and computational modeling to evaluate the initiation and propagation of fatigue cracks. Implementing these methods enhances the reliability and safety of components subjected to cyclic loading by optimizing maintenance schedules and preventing unexpected fractures.

Prevention Strategies for Fatigue and Fracture

Prevention strategies for fatigue and fracture revolve around controlling stress concentrations through material selection, surface treatments, and design improvements to distribute loads evenly. Regular inspections, non-destructive testing methods, and monitoring techniques help detect early signs of cracking or fatigue damage, enabling timely maintenance. Implementing proper load management, such as avoiding overloads and reducing cyclic stresses, significantly enhances structural durability and minimizes the risk of catastrophic failures.

Case Studies: Real-World Failures Due to Fatigue and Fracture

Case studies reveal that fatigue failures often occur in aircraft wings and bridges due to repetitive stress cycles leading to crack initiation and growth, whereas fracture failures are typically sudden and catastrophic, as seen in high-impact collisions or overload conditions in pipelines and structural steel components. In the Silver Bridge collapse of 1967, a fatigue crack propagated unnoticed, resulting in a sudden fracture and tragic failure. These real-world examples emphasize the critical need for regular inspection and maintenance to detect fatigue cracks before they develop into complete fractures.

Stress-Life (S-N) Curve

The Stress-Life (S-N) curve characterizes fatigue by depicting the relationship between cyclic stress amplitude and the number of cycles to failure, contrasting with fracture mechanics that focus on crack initiation and propagation under static or dynamic loads.

Crack Propagation

Crack propagation in fatigue involves the gradual extension of microscopic cracks under cyclic loading, leading to fracture once the crack reaches a critical size.

Endurance Limit

Fatigue failure occurs when cyclic stresses exceed a material's Endurance Limit, beyond which fractures develop even if peak stresses are below the ultimate tensile strength.

Low-Cycle Fatigue

Low-cycle fatigue describes material failure caused by high stress levels inducing plastic deformation and fracture within a relatively low number of loading cycles.

Brittle Fracture

Brittle fracture occurs suddenly in materials under stress without significant plastic deformation, often triggered by fatigue cracks propagating through microstructural weaknesses.

Fatigue Crack Initiation

Fatigue crack initiation occurs due to localized cyclic stresses causing microstructural damage and persistent slip bands that evolve into microscopic cracks before propagating into fractures.

Paris' Law

Paris' Law quantifies fatigue crack growth rate by relating the crack growth per cycle (da/dN) to the stress intensity factor range (DK), providing a predictive model to distinguish fatigue failure from instantaneous fracture.

Fracture Toughness (K_IC)

Fracture toughness (K_IC) quantifies a material's resistance to crack propagation, distinguishing brittle fracture behavior from fatigue-induced crack growth under cyclic loading.

Miner’s Rule

Miner's Rule quantifies fatigue damage by summing the ratios of applied cycle counts to failure cycle counts for each stress level, predicting cumulative fatigue failure before a fracture occurs.

Ductile-to-Brittle Transition

The Ductile-to-Brittle Transition significantly influences fatigue and fracture behavior by reducing material toughness and increasing crack propagation rates at lower temperatures.

fatigue vs fracture Infographic

njnir.com

njnir.com