Fluid couplings transmit torque smoothly between engine and transmission by using hydraulic fluid to absorb shock and vibrations, but they do not multiply torque. Torque converters enhance power delivery by providing torque multiplication during acceleration, improving vehicle performance in varying load conditions. Both devices rely on fluid dynamics, yet torque converters offer greater versatility and efficiency in automotive applications.

Table of Comparison

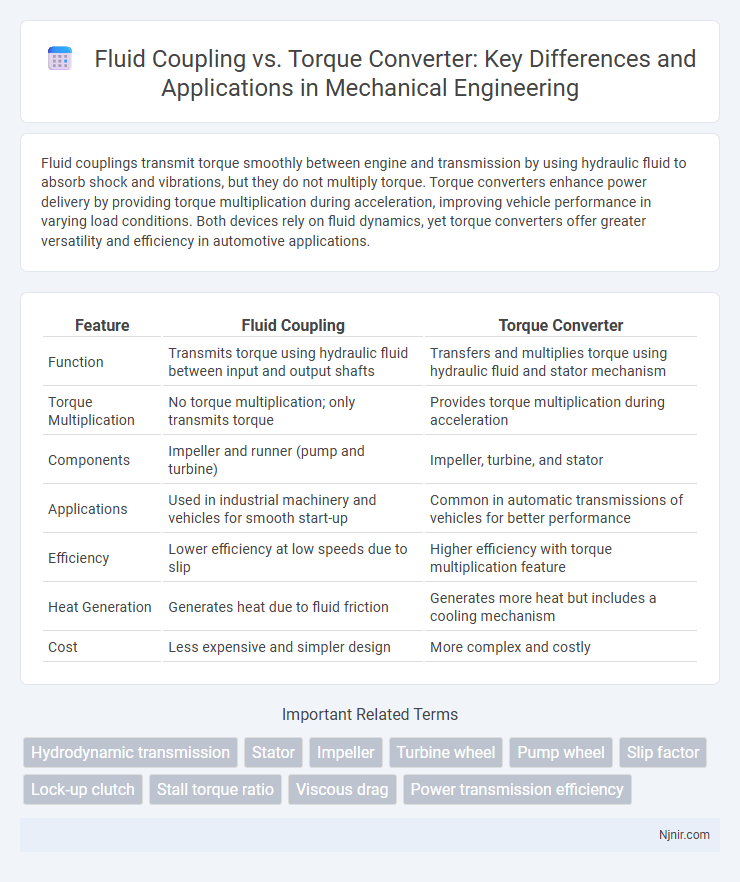

| Feature | Fluid Coupling | Torque Converter |

|---|---|---|

| Function | Transmits torque using hydraulic fluid between input and output shafts | Transfers and multiplies torque using hydraulic fluid and stator mechanism |

| Torque Multiplication | No torque multiplication; only transmits torque | Provides torque multiplication during acceleration |

| Components | Impeller and runner (pump and turbine) | Impeller, turbine, and stator |

| Applications | Used in industrial machinery and vehicles for smooth start-up | Common in automatic transmissions of vehicles for better performance |

| Efficiency | Lower efficiency at low speeds due to slip | Higher efficiency with torque multiplication feature |

| Heat Generation | Generates heat due to fluid friction | Generates more heat but includes a cooling mechanism |

| Cost | Less expensive and simpler design | More complex and costly |

Introduction to Fluid Coupling and Torque Converter

Fluid coupling and torque converter are both essential components in automatic transmissions, providing smooth power transfer between the engine and drivetrain without a direct mechanical connection. Fluid coupling uses hydraulic fluid to transmit torque through a pair of turbine and pump impellers, enabling slip and cushioning sudden loads for smoother vehicle operation. Torque converters enhance this principle by incorporating a stator that multiplies torque, improving acceleration and efficiency during varying engine speeds.

Fundamental Working Principles

Fluid coupling transmits torque from the engine to the transmission using a hydraulic fluid medium, relying on the interaction between the impeller and the turbine to transfer rotational energy with minimal slippage. Torque converters extend this principle by incorporating a stator, which redirects fluid flow to multiply torque during acceleration, enhancing power transmission efficiency and vehicle performance. The fundamental difference lies in the torque converter's ability to provide torque multiplication, unlike fluid coupling, which primarily serves as a smooth mechanical link.

Key Components Comparison

Fluid couplings consist primarily of an impeller, turbine, and housing, facilitating smooth power transmission without torque multiplication. Torque converters include these same components but add a stator, which redirects fluid flow to multiply torque and improve efficiency during acceleration. The presence of the stator in torque converters distinguishes their key component design, enabling enhanced vehicle performance compared to fluid couplings.

Power Transmission Mechanisms

Fluid couplings transmit power through hydrodynamic fluid movement, providing smooth torque transfer without direct mechanical connection, ideal for reducing shock loads in drivetrains. Torque converters enhance this mechanism by incorporating a stator that redirects fluid flow, multiplying torque during acceleration and improving power delivery efficiency. Both systems rely on fluid dynamics, but torque converters offer variable torque multiplication, making them more versatile in automotive powertrain applications.

Efficiency and Performance Analysis

Fluid couplings provide smooth torque transmission with moderate efficiency, primarily used for reducing shock loads in mechanical systems without torque multiplication. Torque converters offer improved performance through torque multiplication, enhancing vehicle acceleration and overall drivetrain efficiency, especially at low speeds. Efficiency differences arise from the torque converter's complex hydraulic design, which can cause higher fluid drag losses compared to the simpler fluid coupling mechanism.

Applications in Mechanical Systems

Fluid couplings are primarily used in mechanical systems for smooth starting and torque transmission in industrial machinery such as conveyors, crushers, and pumps, where controlled acceleration and overload protection are essential. Torque converters are integral to automotive transmissions and heavy equipment, providing variable torque multiplication and enabling seamless gear shifts in automatic transmissions. Both devices enhance mechanical system performance by optimizing power transfer, but torque converters add torque multiplication, making them suitable for dynamic load variations.

Advantages and Limitations

Fluid couplings provide smooth power transmission by using hydraulic fluid to transfer rotational energy, reducing shock loads and minimizing mechanical wear, which enhances the longevity of connected components; however, they lack torque multiplication, resulting in limited performance during startup or under heavy load conditions. Torque converters offer torque multiplication, improving vehicle acceleration and load-handling capabilities by using a stator to redirect fluid flow and increase torque output, but this complexity leads to higher costs, increased heat generation, and potential efficiency losses at cruising speeds. While fluid couplings excel in simplicity and durability, torque converters deliver superior performance versatility albeit with greater mechanical complexity and maintenance requirements.

Maintenance and Durability Considerations

Fluid couplings require less maintenance due to their simpler design with fewer moving parts, resulting in lower wear and longer service intervals. Torque converters have more complex components like stators and lock-up clutches, which may increase maintenance frequency and repair costs over time. Durability of fluid couplings excels in consistent operations, while torque converters provide enhanced performance but can experience accelerated wear under heavy load and high-temperature conditions.

Selection Criteria for Industrial Use

Fluid coupling is selected for industrial applications requiring smooth start-up and protection against shock loads due to its simple design and cost-effectiveness. Torque converters are preferred when variable torque multiplication and stall torque capacity are needed, offering better control and efficiency in heavy-duty machinery. Key selection factors include load characteristics, required torque multiplication, speed variation, and system complexity.

Future Trends and Technological Advancements

Future trends in fluid coupling and torque converter technologies emphasize increased efficiency and integration with electric and hybrid powertrains. Advancements include the development of smart torque converters with adaptive control systems and fluid couplings utilizing improved materials for reduced energy loss. Innovations in electronic control units (ECUs) and sensor technologies enable real-time optimization of torque transfer, enhancing vehicle performance and fuel economy.

Hydrodynamic transmission

Fluid couplings provide smooth hydrodynamic transmission by transmitting torque through a fluid medium without gear reduction, while torque converters enhance hydrodynamic transmission efficiency by incorporating a stator to multiply torque and improve vehicle acceleration.

Stator

The stator in a torque converter enhances torque multiplication by redirecting fluid flow between the pump and turbine, a feature absent in fluid couplings where no torque multiplication occurs.

Impeller

The impeller in a torque converter features curved blades designed to transfer fluid efficiently to the turbine, enabling torque multiplication, whereas the impeller in a fluid coupling primarily transmits torque without multiplication through a simpler blade design.

Turbine wheel

The turbine wheel in a torque converter features a stator that enhances torque multiplication, unlike the simpler turbine wheel in a fluid coupling which solely transmits torque without amplification.

Pump wheel

The pump wheel in a fluid coupling transfers mechanical power by fluid motion without torque multiplication, while in a torque converter, it also enables torque multiplication through its interaction with the turbine and stator.

Slip factor

Fluid couplings exhibit higher slip factors around 5-10%, whereas torque converters typically reduce slip to less than 2% by employing a stator to enhance torque multiplication and improve drivetrain efficiency.

Lock-up clutch

A torque converter with a lock-up clutch improves fuel efficiency and drivability by mechanically linking the engine to the transmission, unlike a fluid coupling that lacks this feature and solely relies on fluid dynamics for torque transfer.

Stall torque ratio

The torque converter offers a significantly higher stall torque ratio than a fluid coupling, enhancing engine torque multiplication during vehicle startup.

Viscous drag

Torque converters exhibit higher viscous drag than fluid couplings due to their complex stator design, resulting in increased energy loss and reduced efficiency at low speeds.

Power transmission efficiency

Fluid couplings offer lower power transmission efficiency compared to torque converters due to the absence of torque multiplication capabilities, resulting in higher energy losses during operation.

fluid coupling vs torque converter Infographic

njnir.com

njnir.com