Ball screws offer higher efficiency and precision than lead screws due to their rolling motion, which reduces friction and wear. Lead screws, typically simpler and less expensive, rely on sliding contact, leading to lower efficiency and faster wear under heavy loads. Ball screws are preferable in applications requiring high speed and accuracy, while lead screws are suitable for low-speed, low-load conditions where cost is a primary concern.

Table of Comparison

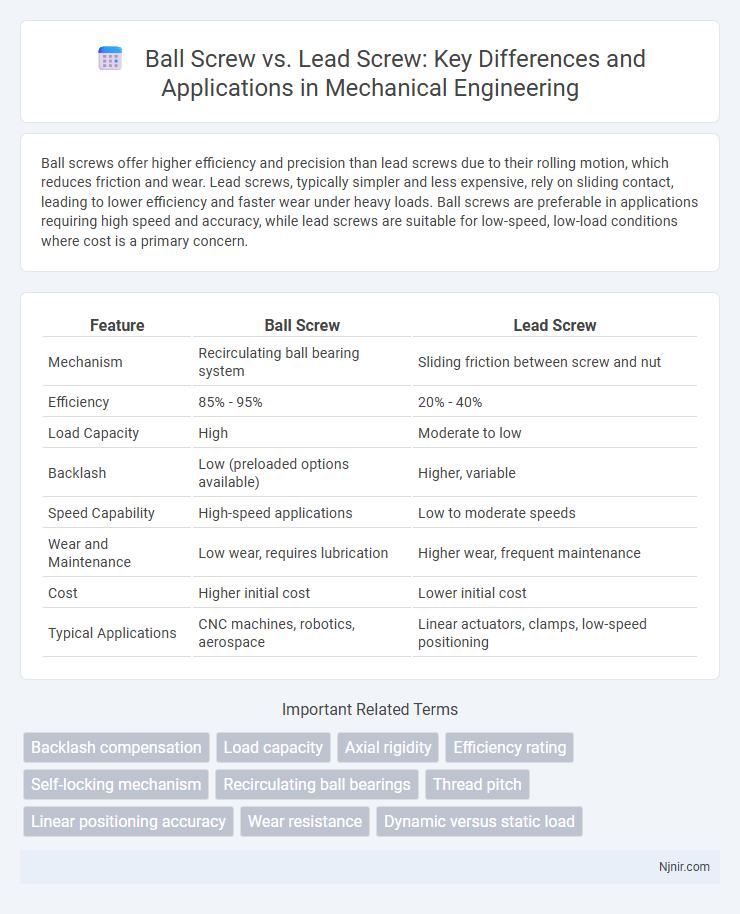

| Feature | Ball Screw | Lead Screw |

|---|---|---|

| Mechanism | Recirculating ball bearing system | Sliding friction between screw and nut |

| Efficiency | 85% - 95% | 20% - 40% |

| Load Capacity | High | Moderate to low |

| Backlash | Low (preloaded options available) | Higher, variable |

| Speed Capability | High-speed applications | Low to moderate speeds |

| Wear and Maintenance | Low wear, requires lubrication | Higher wear, frequent maintenance |

| Cost | Higher initial cost | Lower initial cost |

| Typical Applications | CNC machines, robotics, aerospace | Linear actuators, clamps, low-speed positioning |

Introduction to Ball Screws and Lead Screws

Ball screws and lead screws are mechanical devices used to convert rotational motion into linear motion with high precision and efficiency in various machinery applications. Ball screws utilize recirculating ball bearings to reduce friction and increase movement accuracy, making them ideal for CNC machines and robotics. Lead screws rely on a threaded shaft and nut, providing simpler, cost-effective linear motion solutions with moderate accuracy and load capacity.

Fundamental Design Differences

Ball screws feature recirculating ball bearings that reduce friction and enable high efficiency and precision in linear movement, making them ideal for applications requiring rapid and accurate positioning. Lead screws rely on a threaded shaft and nut mechanism with direct sliding contact, resulting in higher friction and lower efficiency but simpler design and lower cost. The fundamental design difference lies in the use of rolling elements in ball screws versus sliding contact in lead screws, impacting load capacity, wear resistance, and mechanical efficiency.

Load Capacity and Efficiency Comparison

Ball screws offer higher load capacity due to their rolling element design, which minimizes friction and enables handling of heavier loads compared to lead screws. Lead screws rely on sliding friction between the screw and nut, resulting in lower efficiency, typically around 20-40%, whereas ball screws achieve efficiency rates of 90% or higher. This significant difference in efficiency also reduces heat generation and wear in ball screws, enhancing their suitability for high-precision and high-load applications.

Precision and Accuracy in Motion Control

Ball screws provide higher precision and superior accuracy in motion control due to their rolling contact mechanism, which minimizes friction and backlash compared to lead screws. Lead screws, relying on sliding friction, have inherent limitations in repeatability and positioning accuracy, making them less suitable for applications requiring tight tolerances. The reduced friction in ball screws results in smoother motion and consistent torque transmission, enhancing overall system performance in high-precision environments.

Wear, Friction, and Maintenance Requirements

Ball screws exhibit significantly lower friction and wear due to rolling element contact, resulting in higher efficiency and longer service life compared to lead screws, which rely on sliding motion. Lead screws experience greater friction, leading to increased wear and more frequent lubrication and maintenance to prevent premature failure. Maintenance requirements for ball screws are generally less intensive, involving periodic inspections and lubrication, whereas lead screws demand consistent lubrication and adjustment to manage wear and maintain performance.

Speed and Performance Capabilities

Ball screws offer higher speed and superior performance capabilities compared to lead screws due to their reduced friction and increased efficiency, enabling faster linear motion with minimal heat generation. Lead screws, while typically slower, provide greater load-carrying capacity and better self-locking characteristics, making them suitable for applications requiring precise positioning without backlash. The choice between ball and lead screws depends on the balance between required speed, load capacity, and accuracy in specific mechanical systems.

Applications in Mechanical Engineering

Ball screws are widely used in CNC machines, robotics, and precision automation due to their high efficiency, low friction, and ability to handle heavy loads with minimal backlash. Lead screws find applications in 3D printers, linear actuators, and adjustable medical equipment where simplicity, lower cost, and moderate load capacity are sufficient. Mechanical engineers select ball screws for high-speed, high-accuracy motion control, while lead screws are preferred for low-speed, lower-precision tasks with less frequent movement.

Cost Analysis and Economic Considerations

Ball screws typically involve higher initial costs due to precision manufacturing and materials but offer greater efficiency and longer lifespan, reducing maintenance expenses over time. Lead screws are generally more economical upfront with simpler design and lower production costs but experience higher wear and energy losses, leading to increased replacement and operational costs. Choosing between ball screw and lead screw requires balancing upfront investment against long-term maintenance and efficiency expenses to optimize overall economic benefits.

Selection Criteria for Engineers

Engineers select between ball screws and lead screws based on load capacity, efficiency, and precision requirements. Ball screws offer higher efficiency and accuracy due to rolling elements, making them ideal for high-speed and heavy load applications. Lead screws provide simpler design and lower cost, suitable for low-speed, low-load scenarios where self-locking feature is beneficial.

Summary: Choosing Between Ball Screws and Lead Screws

Ball screws offer high efficiency and precision due to their rolling contact mechanism, making them ideal for high-speed and heavy-load applications, while lead screws rely on sliding contact, providing better self-locking capabilities and simpler maintenance for slower, lower-load systems. The choice depends on the application's speed, load capacity, accuracy, and whether back-driving resistance is required. Cost differences also influence the decision, with ball screws typically being more expensive but delivering superior performance in demanding environments.

Backlash compensation

Ball screws offer superior backlash compensation through preloaded nut assemblies that minimize axial play, whereas lead screws typically require external mechanisms to achieve comparable backlash reduction.

Load capacity

Ball screws offer higher load capacity and greater efficiency than lead screws due to their rolling contact bearings that reduce friction and wear.

Axial rigidity

Ball screws provide significantly higher axial rigidity than lead screws due to their rolling contact design, which reduces friction and deflection under axial loads.

Efficiency rating

Ball screws offer an efficiency rating of 90-95%, significantly outperforming lead screws, which typically range from 20-50% efficiency due to higher friction losses.

Self-locking mechanism

Ball screws typically lack a self-locking mechanism due to their low friction, whereas lead screws inherently provide self-locking capabilities because of their higher friction and thread geometry.

Recirculating ball bearings

Recirculating ball bearings in ball screws significantly reduce friction and increase efficiency compared to the sliding contact of lead screws, resulting in higher precision and longer lifespan in linear motion applications.

Thread pitch

Ball screws typically feature a larger thread pitch for higher efficiency and faster linear motion compared to the finer thread pitch of lead screws designed for greater mechanical advantage and precise positioning.

Linear positioning accuracy

Ball screws provide superior linear positioning accuracy compared to lead screws due to their reduced friction and minimal backlash, enabling high-precision motion control in CNC machines and industrial automation.

Wear resistance

Ball screws offer superior wear resistance due to their rolling contact design, while lead screws experience higher wear from sliding friction, resulting in shorter service life and more frequent maintenance.

Dynamic versus static load

Ball screws provide higher dynamic load capacity and efficiency for high-speed applications, while lead screws excel in static load handling with better resistance to wear under low-speed or stationary conditions.

Ball screw vs lead screw Infographic

njnir.com

njnir.com